Continuous digital gravure overprinting method

A digital printing and digital technology, applied in the field of gravure digital continuous overprinting, which can solve the problems of incompatibility with large-volume production, inability to repeat overprinting, large color difference, etc. , make up for the effect of repeated overprinting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with specific embodiment and accompanying drawing, the present invention will be further described:

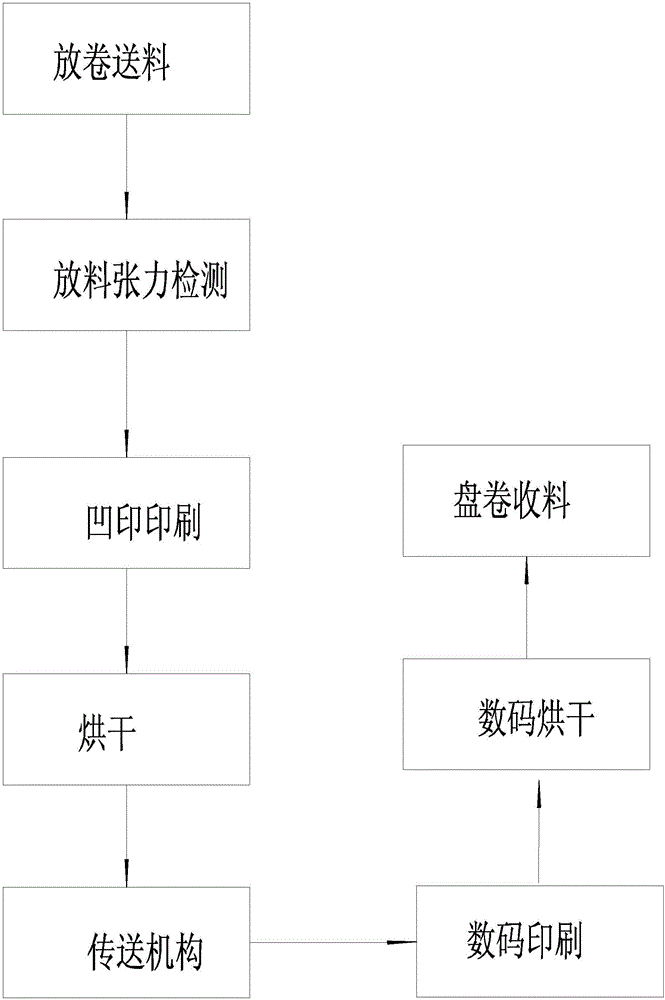

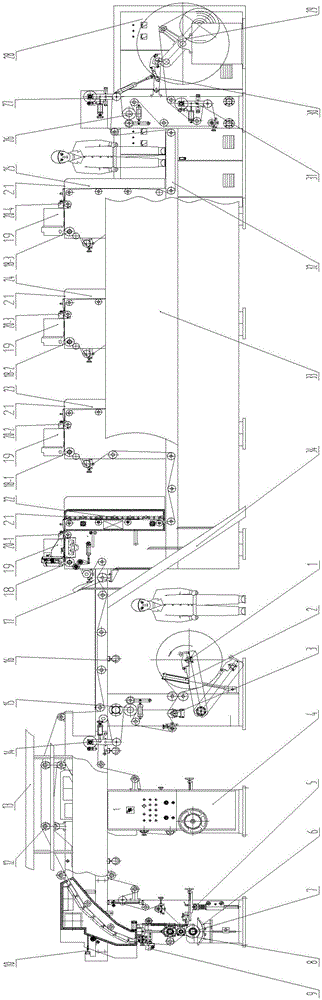

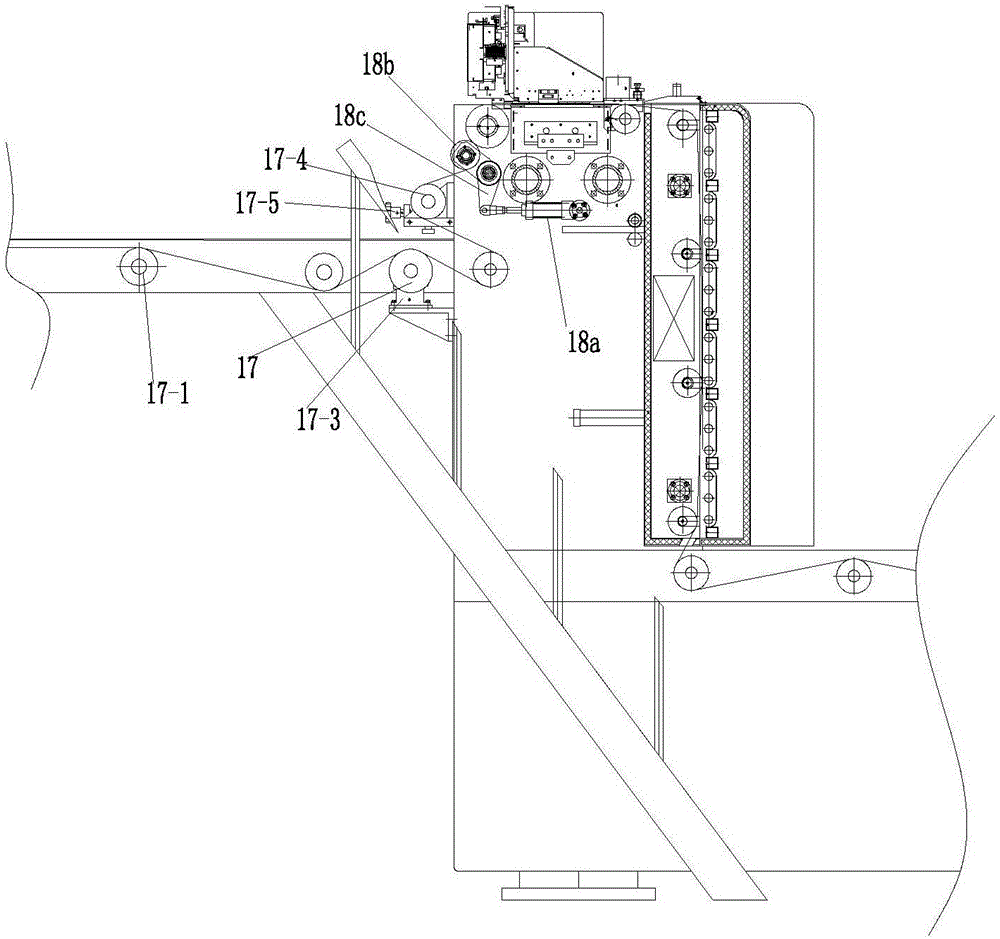

[0021] Refer to attached figure 1 As shown, in the gravure digital continuous overprinting method of the present invention, the gravure combination printing machine is composed of a combination of concave numbers, and the machine is used for printing on roll paper and film, including the following steps: (1) unwinding and feeding , the discharge traction mechanism feeds the printing paper suitable for the entire wall at a preset speed; (2) discharge tension detection, real-time detection of wallpaper raw material tension, and adjusts discharge traction according to the comparison result between real-time tension and tension preset value Mechanism feeding speed; (3) gravure printing, ink printing is carried out on the surface of the printing paper through the printing mechanism, the printing paper is provided with a starting printing mark, and printi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com