A construction method and device for pre-embedding ship bilge keel

A construction method and technology of bilge keel, which are applied in ship construction, ship parts, transportation and packaging, etc., can solve the problems of increased workload of cutting and grinding, potential safety hazards and low precision, and can shorten the installation time of bilge keel, reduce The effect of welding and grinding process, saving working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] A construction method and device for sub-embedded installation of bilge keels of the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments, in order to understand its structure type and usage more clearly. However, it cannot be used to limit the protection scope of the patent of the present invention.

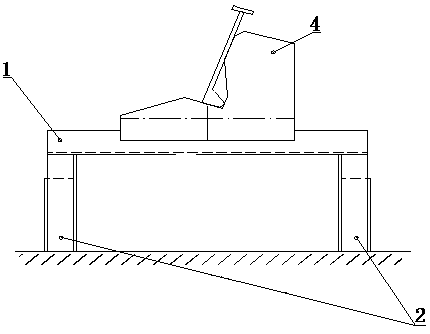

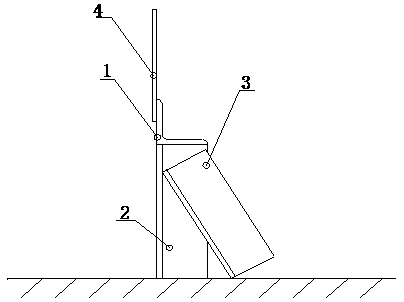

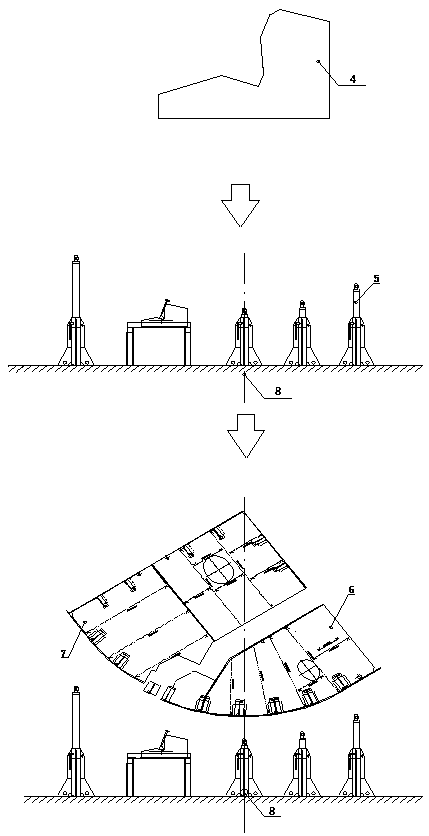

[0036] Such as figure 1 , figure 2 and image 3 Shown, a kind of construction method for pre-embedded installation of bilge keel of ship section, this method comprises the following steps:

[0037] The first step is to draw the bilge keel pre-embedded tire frame process drawing according to the outer plate molding line, the original tire frame data and the bilge keel installation drawing, which includes the shape, height and position of the embedded tire frame, and the 5, the position and height of the flexible tire frame is a conventional tool in the prior art, and will not be repeated here. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com