Positioning installation method of cutter seat of cutter-suction dredger

A cutter suction dredger, positioning and installation technology, applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc., can solve the problems of low efficiency and complex process, and achieve simple process, Improve work efficiency and reduce the effect of measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The positioning and installation method of the cutter seat of the cutter suction dredger according to the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention cannot be limited thereby.

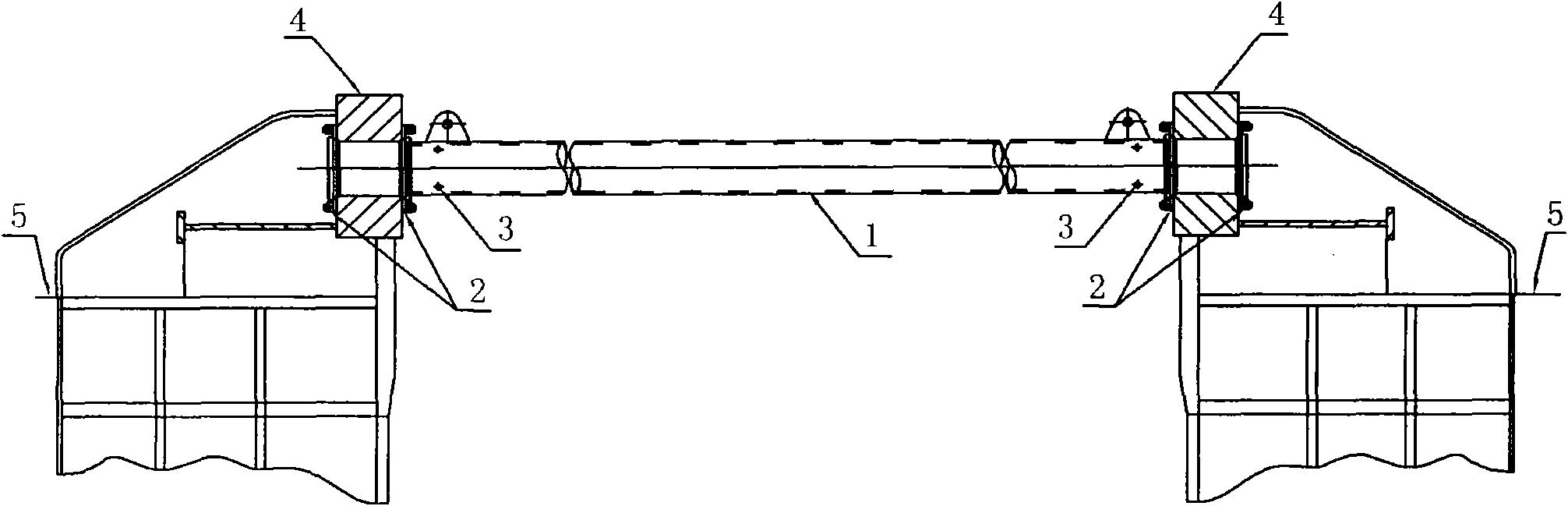

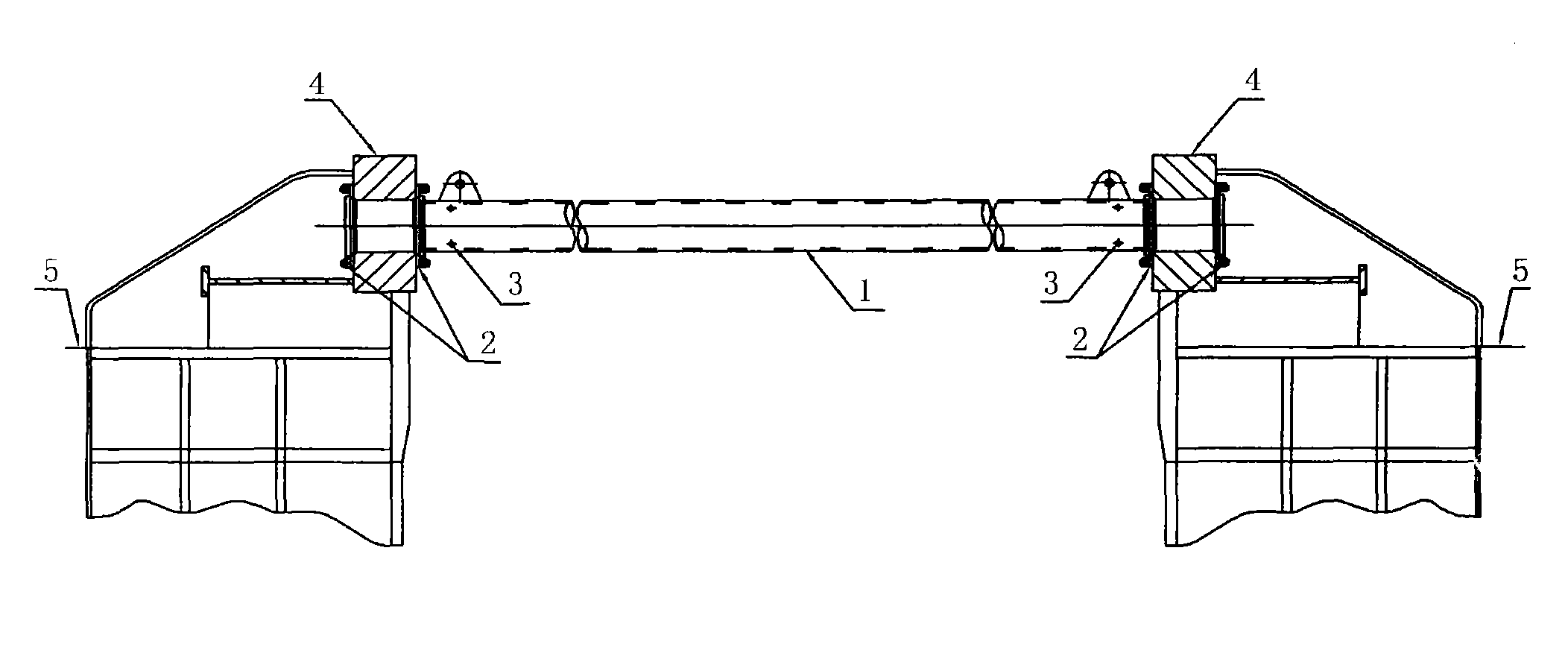

[0014] Such as figure 1 As shown, grooves are installed at both ends of the dummy shaft 1 to install a pair of limit blocks 2. After the dummy shaft 1 is assembled with the two reamer seats 4 on the left and right, each pair of limit blocks 2 is respectively located in the shaft hole of the reamer seat. On both sides, each pair of limit blocks 2 is located on both sides of the shaft hole of the corresponding reamer seat 4, and the distance between the left and right two reamer seats 4 is controlled by two pairs of limit blocks 2; The jack 3 that lever is inserted, this jack 3 can be inserted into lever at any time, whether test craft dummy shaft 1 rotates smo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com