Method for improving ethanol tolerance of synechocystis PCC6803 and application

A technology of PCC6803 and Synechocystis, applied in the field of industrial microorganisms, can solve the problems of reduced growth rate and poor ethanol tolerance, and achieve the effect of improved tolerance and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

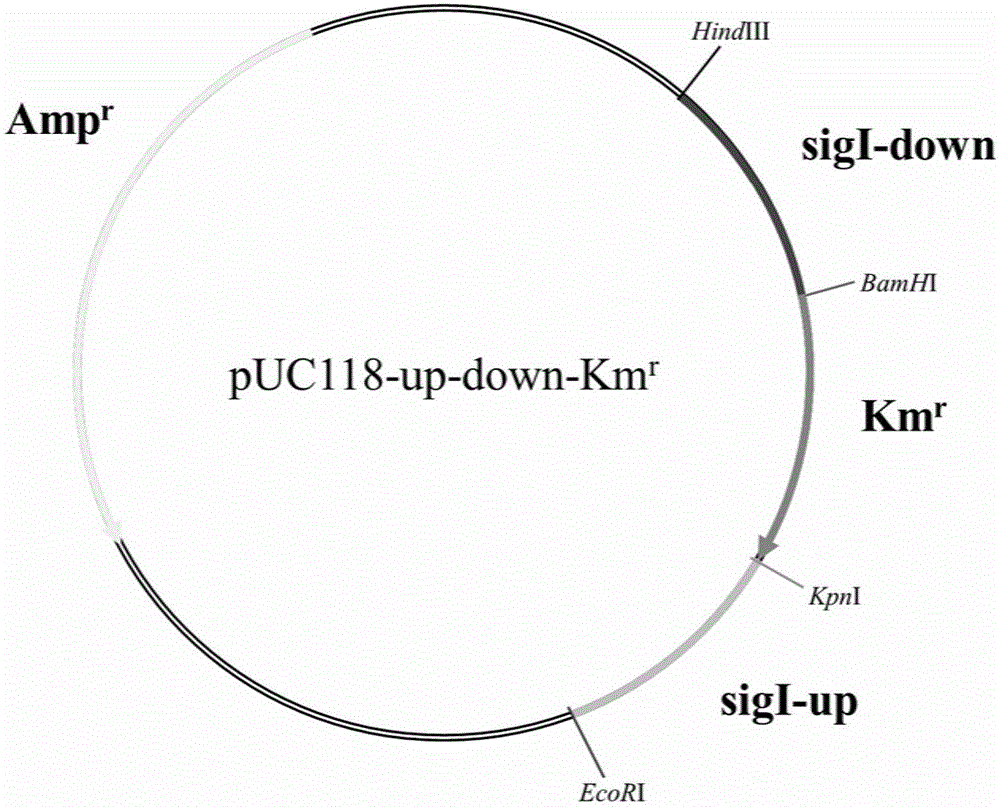

[0023] Homologous recombination double crossover plasmid pUC118-up-down-Km r The build:

[0024] (1) Amplification of the insert:

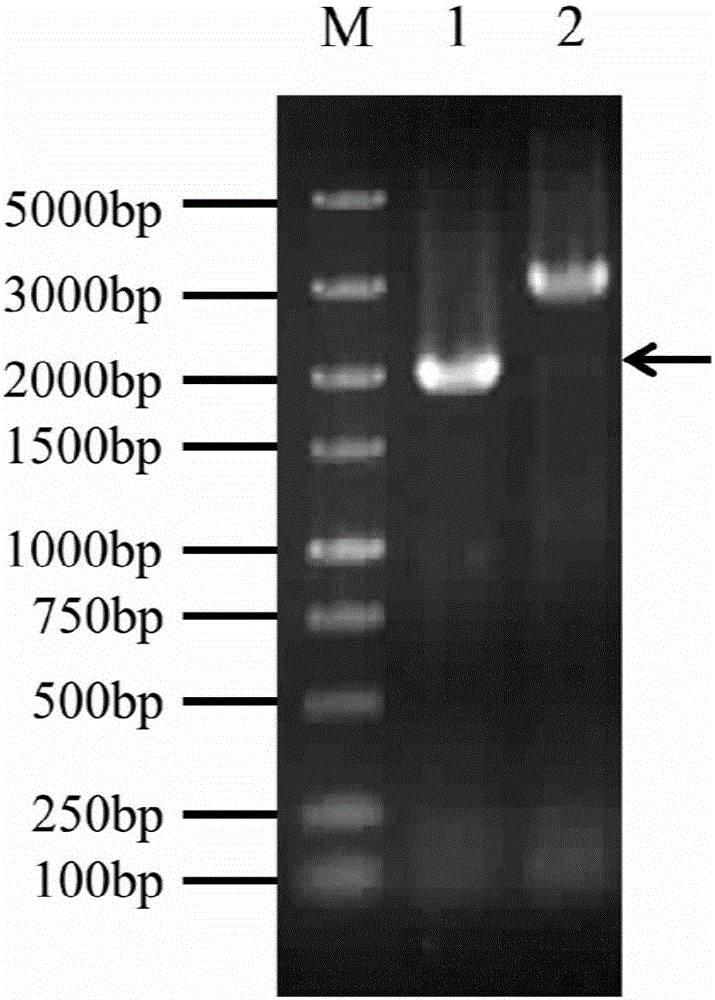

[0025] Using SEQ ID NO: 1 and SEQ ID NO: 2 in the sequence listing as upstream and downstream primers, using the wild-type Synechocystis PCC6803 genome as a template, the upstream sequence sigI-up of the sll0687 gene was obtained by PCR amplification, as shown in SEQ ID NO in the sequence listing Shown in ID NO: 7; using SEQ ID NO: 3 and SEQ ID NO: 4 as the upstream and downstream primers, using the wild-type Synechocystis PCC6803 genome as a template, the downstream sequence sigI-down of the sll0687 gene was obtained by PCR amplification, as shown in Shown in SEQ ID NO: 8; using SEQ ID NO: 5 and SEQ ID NO: 6 as the upstream and downstream primers, using the pET-30b plasmid as a template, the kanamycin gene and its upstream and downstream partial sequences were amplified by PCR Km r , as shown in SEQ ID NO:9. The genome extraction of Synechocy...

Embodiment 2

[0032] Obtainment of Synechocystis PCC6803 strain with significantly improved tolerance to ethanol:

[0033] (1) Plasmid transformation

[0034] pUC118-up-down-Km r After the plasmid was sterilized by filtration with a 0.22 μm microporous membrane, it was loaded into a 2 mL sterile centrifuge tube. A certain amount of BG11 medium (with HEPES buffer added) was added thereto, so that the final concentration of the plasmid was about 10 ng / μL. Take 30 mL of wild-type PCC6803 in logarithmic phase, centrifuge at 6000 rpm for 7 min, and remove the supernatant. Resuspend the algae mud with 20mL of fresh BG11 medium, centrifuge at 6000rpm for 7min, and remove the supernatant. Resuspend the algae mud with plasmid-containing medium. The resuspended algae liquid was cultured at 29°C, 150rpm, and 1400Lux continuous light for 6h. After the algae solution was applied to the solid medium covered with mixed fiber filter membrane and cultured under light for 1 day (upright culture), the me...

Embodiment 3

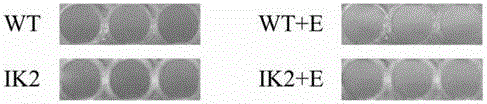

[0040] Analysis of the growth status of IK2 strains under ethanol stress:

[0041] Measure the growth curve of the IK2 algal strain obtained in Synechocystis PCC6803 wild type and Example 2 under 1.5% (v / v) ethanol stress: the algae grown to the logarithmic phase are used as seed liquid and inoculated to 50mL of BG11 medium containing , the starting OD of each bottle of algae 730 = 0.1. Continuous culture for 4 days, sampling OD every day 730 value to draw a growth curve. The culture conditions are 29°C, 150rpm, 1400Lux continuous light. At the beginning of the culture, ethanol was added to the medium of the wild-type and IK2 experimental groups to a final concentration of 1.5% (v / v). The experimental group and the control group each had three parallels.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com