Integrated construction technology of anti-collision wall formwork

A construction technique and anti-collision wall technology, which is applied in the erection/assembly of bridges, bridge parts, buildings, etc., can solve the problems of difficulty in high-altitude protection of anti-collision walls, weak edge protection for high-altitude operations, and low safety of construction personnel. To achieve the effect of perfect safety measures, reduce construction cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

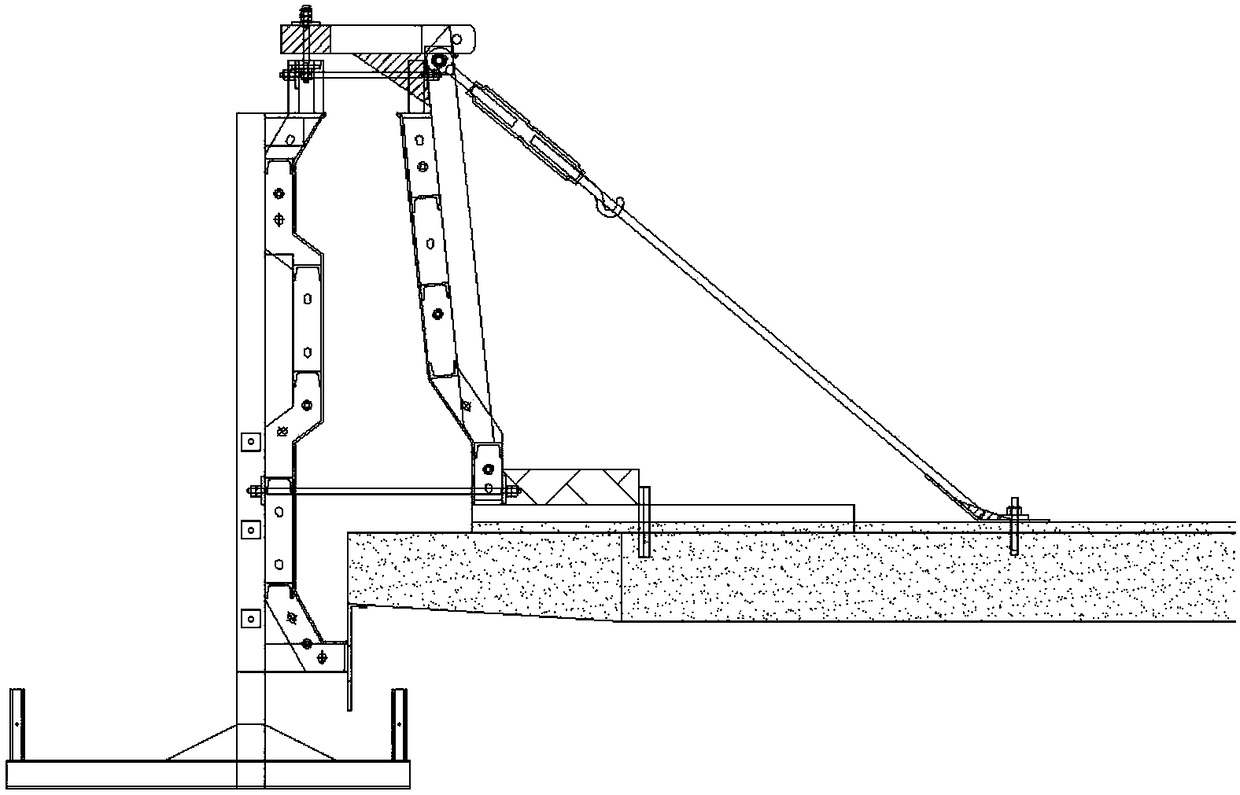

[0037] Such as figure 1 As shown, the formwork integrated construction process of the anti-collision wall is characterized in that it includes the following parts:

[0038] (1) Platform Transformation

[0039] On the outside of the outer formwork of the anti-collision wall, a T-shaped platform is added. The T-shaped platform includes a plurality of T-shaped frames arranged side by side and bamboo plywood laid at the bottom of the T-shaped frame. Each T-shaped frame includes a vertical bar and is perpendicular to the The horizontal bar at the bottom of the vertical bar, the vertical bar of each T-shaped frame is connected with the vertical rib on the outer side of the outer mold by bolts, the bamboo plywood is laid on the upper surface of the horizontal bar of the T-shaped frame, and the outer surface of the horizontal bar of the T-shaped frame There is also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com