Color steel tile clamp with calibrating function based on lever principles

A lever principle, color steel tile technology, applied to roofs, roofs, buildings, etc. where tiles/slate tiles are used, it can solve the problems of easy oxidation and rust, difficult to remove screws, and not installed in place, etc., to enhance practicability and stability, simple and convenient operation, easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

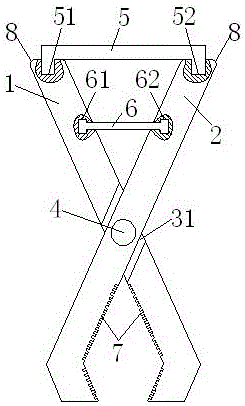

[0030] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, in this embodiment, a color steel tile fixture based on the principle of leverage and with its own calibration function includes a hinge 4, a left splint 1 and a right splint 2 that are hinged together through the hinge 4, and also includes connecting the left splint 1 and the right splint 2 and a locking piece 5 for locking, and a calibration piece 6 connected between the left splint 1 and the right splint 2 and used for calibration.

[0031] The present invention adopts the principle of leverage, and uses the locking member 5 to lock the two left splints 1 and right splints 2 that are hinged together through the hinge 4, so that the present invention does not need to tighten the bolts during the installation and disassembly process, thus making the operation easier Convenience, the present invention also installs the calibration part 6 on the two splints. When the two splints are in...

Embodiment 2

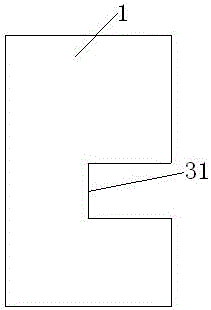

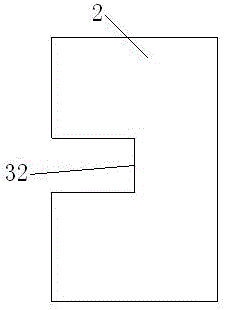

[0033] This embodiment is further limited on the basis of Embodiment 1. In this embodiment, the upper end surface of the left splint 1 is provided with an A locking groove 51, and the upper end surface of the right splint 2 is provided with a B locking groove 52; The two ends of 5 are matched and installed in the A locking groove 51 and the B locking groove 52 respectively.

[0034] The locking member 5 in the present invention is installed in the locking groove provided on the two splints in a clamping manner, and the locking is realized by mutual restriction between the locking groove and the locking member 5. When installing, the user Clamping can be realized by snapping the locking piece 5 into the locking grooves of the two splints without the step of screwing, which makes the operation of the present invention more convenient, and the snap-fit connection method is compared with the threaded connection More stable, thus enhancing the stability of the present invention. ...

Embodiment 3

[0037] This embodiment is further improved on the basis of Embodiment 1. In this embodiment, the side of the left splint 1 opposite to the right splint 2 is provided with an A positioning groove 61, and the right splint 2 corresponds to the A positioning groove 61. The position of B positioning groove 62 is set, and the two ends of the calibrating part 6 are matched and installed in A positioning groove 61 and B positioning groove 62 respectively.

[0038] The calibrating part 6 of the present invention is inserted into the positioning grooves provided on the two clamping blocks in the way of mortise joint. Using the above method, while realizing the connection, the calibration function can be realized, and the second locking effect can be realized, so that the present invention The installation and disassembly of the invention is more convenient, and the calibrating part 6 is used together with the locking part 5, which can enhance the stability of the present invention after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com