A roof clamp for easy installation

A clamp and splint technology, applied in the field of roof clamps that are easy to install, can solve the problems of reducing the work efficiency of the installer, narrow operation space, troublesome operation, etc., and achieve the effect of simple and convenient clamping operation, easy installation and disassembly, and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

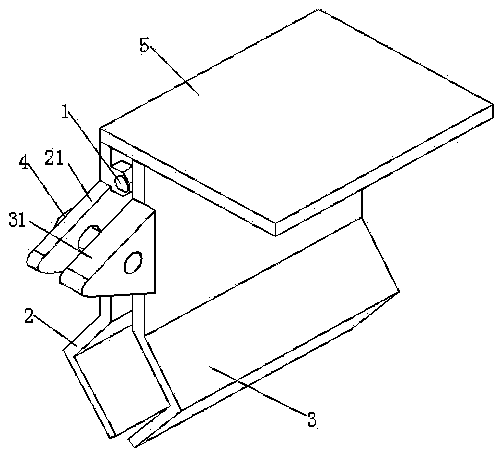

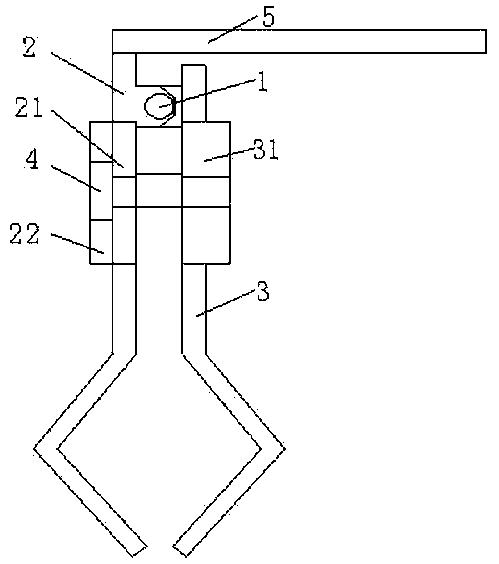

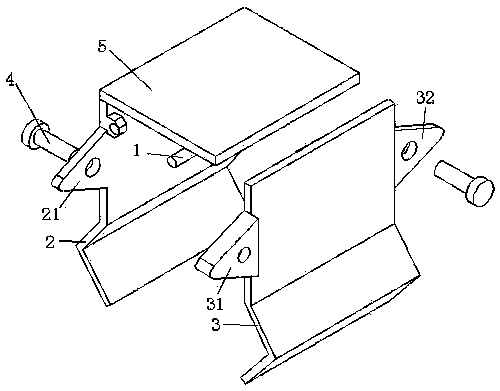

[0023] like figure 1 , figure 2 , image 3 As shown, in this embodiment, a roof clamp that is easy to install includes a hinge 1, a splint A 2 and a splint B 3 that are hinged together through the hinge 1, and is arranged at a corresponding position above the splint A 2 and is used to install the rest of the components. The supporting plate 5, the left side of the A splint 2 extends outwards with an A left fixing ear 21, and the right side of the A splint 2 extends outwards with an A right fixing ear 22, and the two sides of the B splint 3 are respectively provided with A Left fixed ear 21, A right fixed ear 22 correspond to B right fixed ear 31 and B left fixed ear 32, also includes A left fixed ear 21 and B right fixed ear 31, B left fixed ear 32 and A right fixed ear 22 Connectors 4 connected together.

[0024] As a specific implementation of this embodiment, the A splint 2 is provided with hinged A bosses, and the A bosses are located on both sides of the A splint 2, a...

Embodiment 2

[0028] This embodiment is further limited on the basis of Embodiment 1. In this embodiment, the above-mentioned connector 4 is a screw, adopts the above-mentioned structure, and adopts threaded connection and locking, so that the present invention is easy to install and disassemble, and its working performance is reliable. Strong practicality.

Embodiment 3

[0030] This embodiment is further limited on the basis of the above embodiments. In this embodiment, the thickness of the above-mentioned left fixing ear 21 of A is the same as that of the splint 2 of A, and the thickness of the right fixing ear 22 of A is greater than the thickness of the left fixing ear 21 of A. , the thickness of the right fixing ear 31 of B is the same as the thickness of the right fixing ear 22 of A, the thickness of the left fixing ear 32 of B is the same as the thickness of the left fixing ear 21 of A; In the through holes passing through the connecting piece 4 , the A right fixing ear 22 and the B right fixing ear 31 are provided with threaded holes matching with the connecting piece 4 .

[0031] With the above-mentioned structure, when the present invention is locked by screws, the screw can pass through a fixed ear with a thinner thickness, and be screwed with the fixed ear on the thicker side, increasing the thread of the screw in the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com