Pump and assembly method of the same

An assembly method and impeller technology, applied to pumps, components of pumping devices for elastic fluids, pump components, etc., can solve problems such as severe loss, complex processing, assembly, design, and durability issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

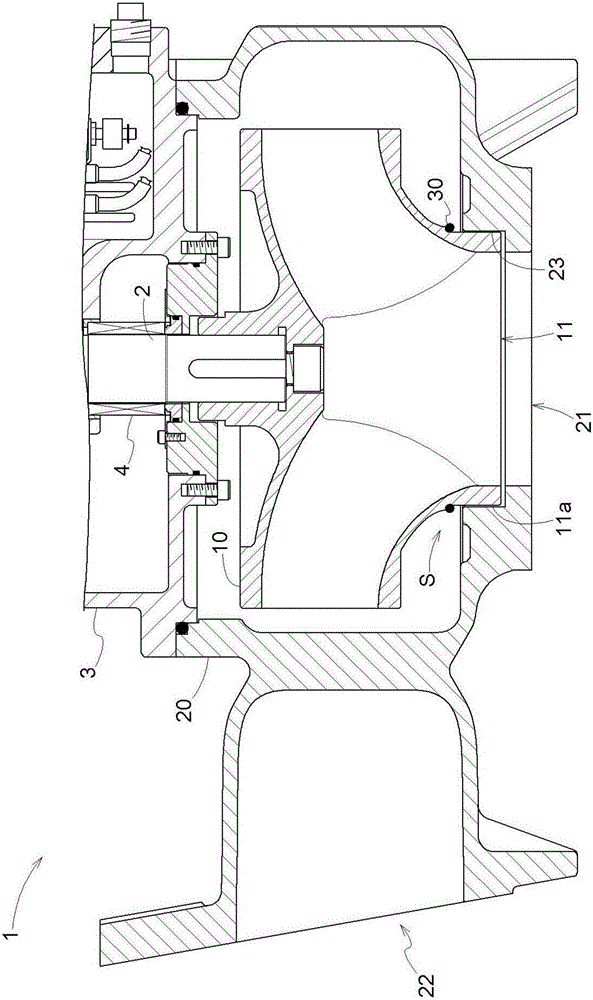

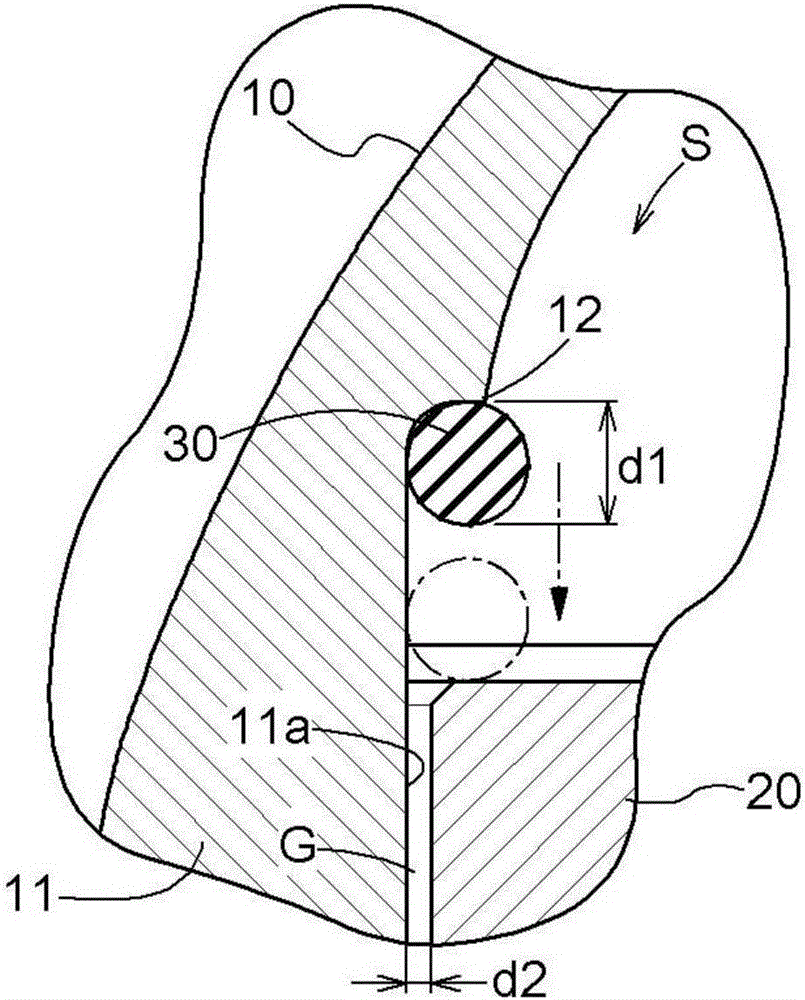

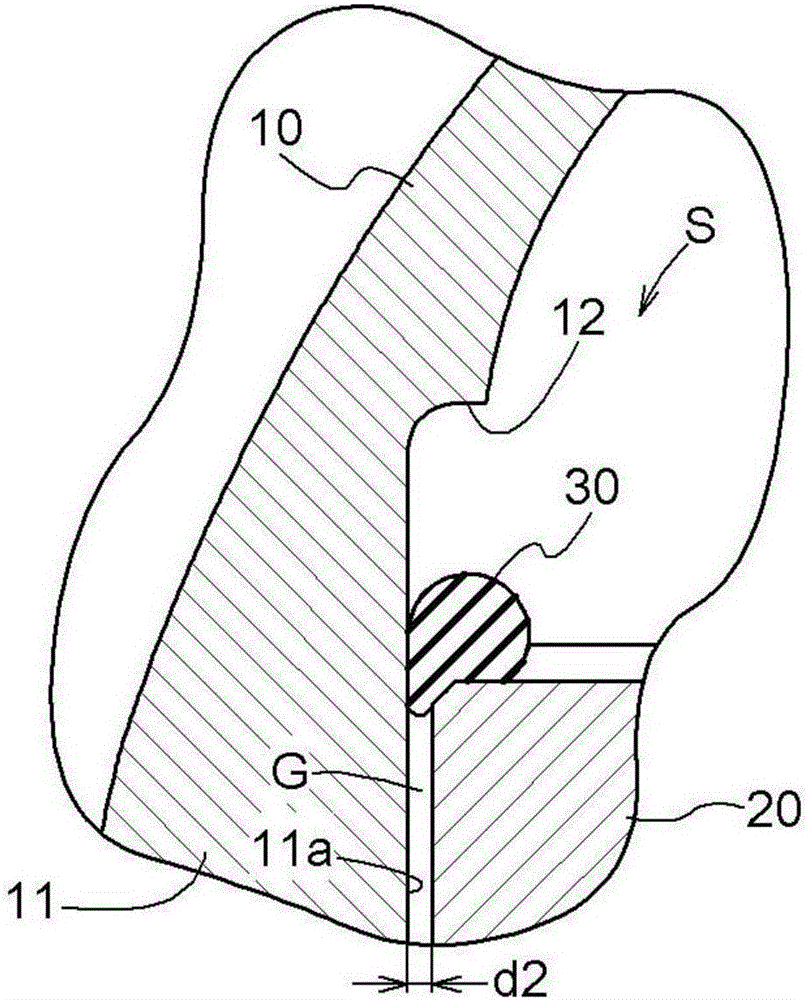

[0030] Embodiments of the pump and the method of assembling the pump according to the present invention will be described with reference to the drawings. The pump 1 of the present embodiment includes an impeller 10 and a pump housing 20 that accommodates the impeller 10 . In the pump 1 , an annular gap G is formed between the outer peripheral surface 11 a of the suction port 11 of the impeller 10 and the housing 20 . In addition, a sealing member 30 is provided on the outer peripheral surface 11a of the suction port 11 on the inner side of the casing 20 than the annular gap G, and the sealing member 30 is accommodated in the suction port so as to be movable in the axial direction into an open state and a closed state. 11, the open state is a state in which the sealing member 30 is separated from the annular gap G, and the closed state is a state in which the sealing member 30 moves from the open state to the annular gap G side to block the annular gap G. Thereby, assembly and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com