Heat dissipation fan blade structure and heat dissipation fan

A heat dissipation fan and fan blade technology, which is applied to non-variable pumps, pump components, components of pumping devices for elastic fluids, etc., can solve problems such as reducing fan characteristics, increasing noise, and unstable fan flow field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The above-mentioned purpose of the present invention and its structural and functional characteristics will be described based on the preferred embodiments of the accompanying drawings.

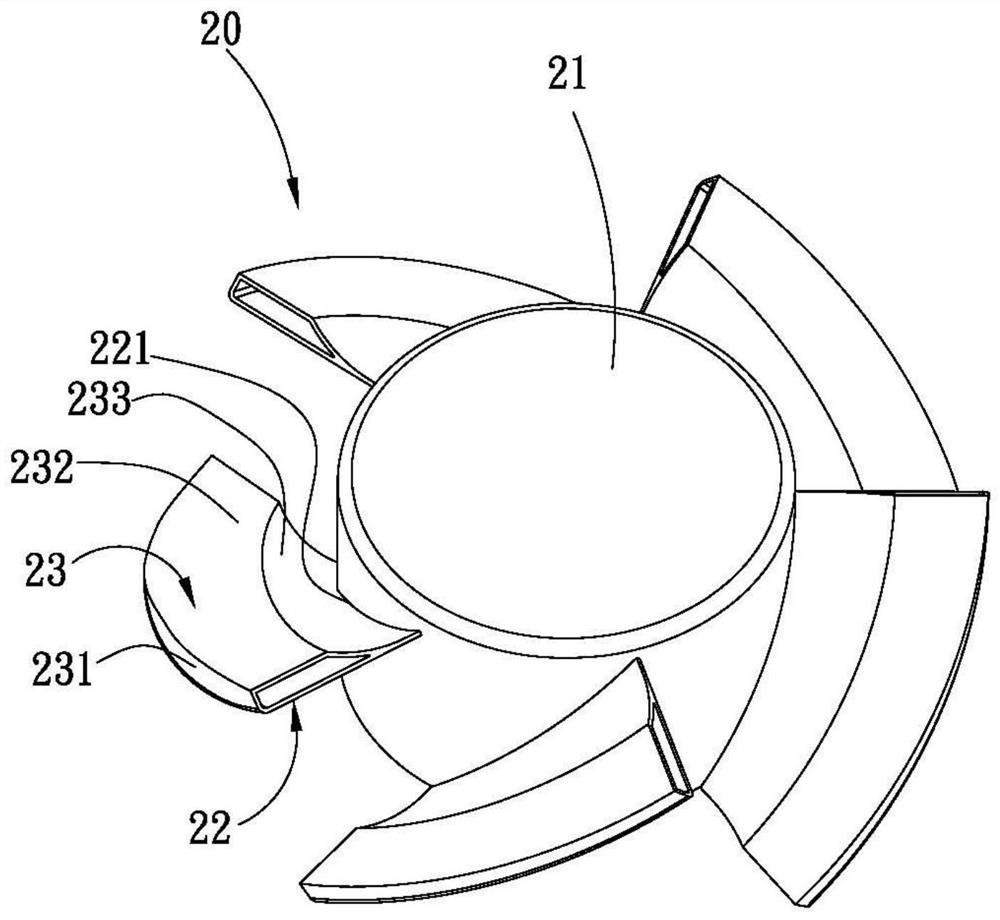

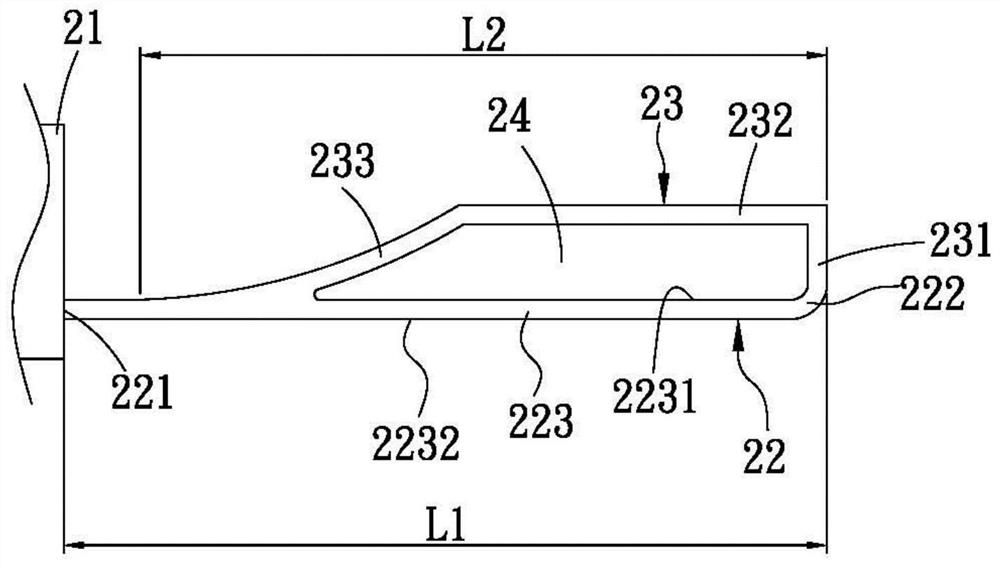

[0045] Please refer to figure 2 It is a three-dimensional schematic diagram of a cooling fan with a cooling blade structure according to the present invention; Figure 3A A cross-sectional schematic diagram of an annular structure for a cooling fan blade structure; Figure 3B-3E It is a cross-sectional schematic diagram of an alternative implementation of the annular structure of the cooling fan blade structure. As shown in the figure, the cooling fan 20 of the present invention includes a hub 21 and a plurality of main fan blades 22 . The main fan blades 22 are arranged around the outer side of the hub 21, each main fan blade 22 has a root portion 221 and an end portion 222, and the root portion 221 and the end portion 222 are respectively arranged on opposite ends of the main fan ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com