Detachable durable gear

A gear, durable technology, applied in the direction of gear lubrication/cooling, belt/chain/gear, elements with teeth, etc., to achieve the effect of improving dynamic balance, saving production costs, and shortening repair time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

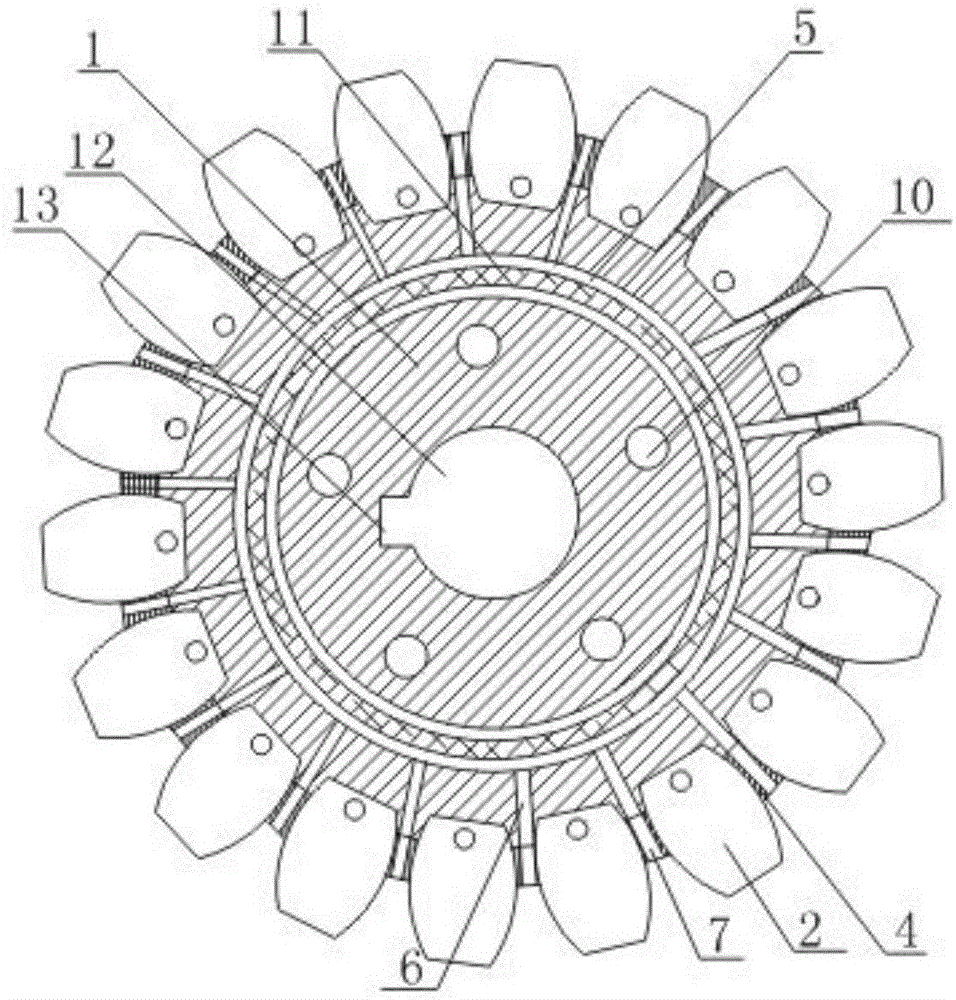

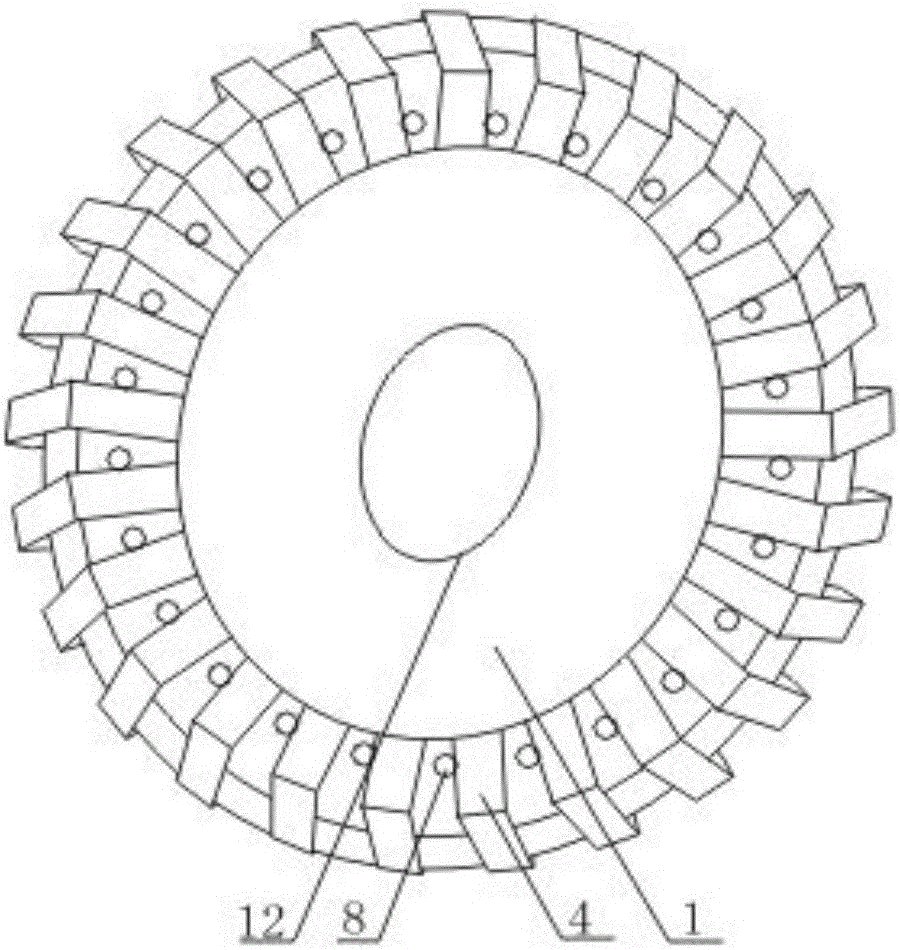

[0028] The detachable durable gear includes a gear body 1 and a plurality of gear teeth 2 evenly distributed on the outer circumference of the gear body 1. The lower end of the gear teeth 2 is provided with a slot 3, and the gear teeth 2 are stuck in the gear body 1 through the slot 3. On the outer circular side wall, the gear body 1 and the gear teeth 2 are connected by bolts; the outer circumference of the gear body 1 is uniformly provided with a plurality of positioning protrusions 4, the gear teeth 2 are located between the adjacent positioning protrusions 4, and the positioning protrusions 4 The height is less than the height of the gear teeth 2; the inside of the gear body 1 is provided with an annular chamber 5 and several oil guide pipes 6 communicating with the annular chamber 5, and an oil outlet hole communicating with the oil guide pipe 6 is opened on the positioning protrusion 4 7.

Embodiment 2

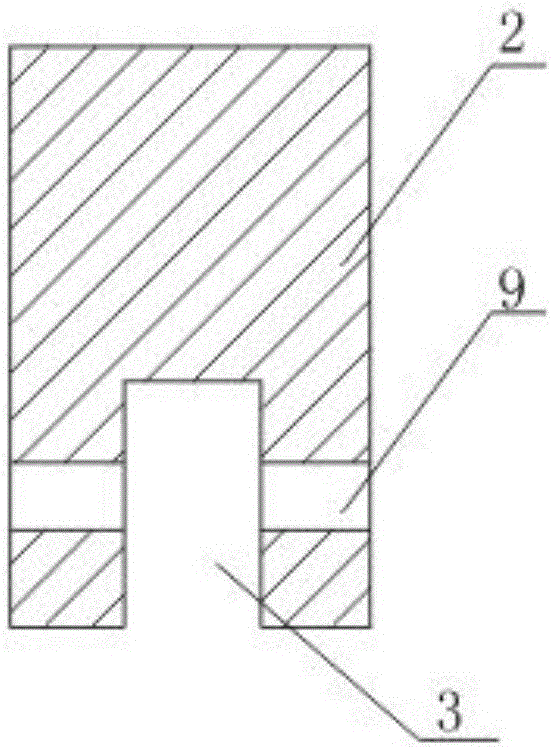

[0030] In this embodiment, on the basis of Embodiment 1, there are several threaded holes A8 evenly distributed on the outer peripheral edge of the gear body 1 for installing the gear teeth 2, and the two sides of the slot 3 of the gear teeth 2 are respectively provided with Threaded hole B9 matched with threaded hole A8.

Embodiment 3

[0032] In this embodiment, on the basis of embodiment 1 or embodiment 2, the gear body 1 is provided with a plurality of weight reducing holes 10 , and the plurality of weight reducing holes 10 are evenly distributed on the gear body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com