Disposable air inflating detonation split gas detonator and manufacturing method thereof

A split-type, one-time technology, which is applied in the field of blasting devices and gas blasters, can solve the problems of high labor costs and consumable costs, easy deformation of the pipe body, and difficult maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

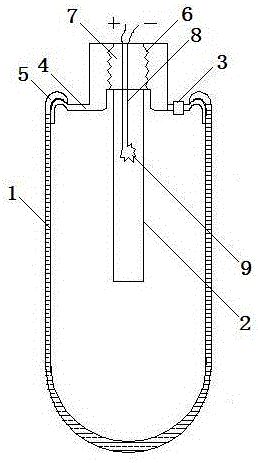

[0115] like figure 1 As shown, a one-time inflatable detonation split-type gas blaster includes an energy storage device 1, a detonating mechanism 2, an inflating mechanism 3, an energy discharge head 4, a wrapping layer 5, an internal thread 6, a sealing head 7, and a lead wire Holes 8 and heating wires 9; the energy storage device 1 is provided with a discharge head 4, the energy storage device 1 fixes the discharge head 4 through the wrapping layer 5, and the middle part of the discharge head 4 is provided with an internal thread 6 and a matching seal Activator 201 is provided at the lower part of head 7 and sealing head 7, and lead wire hole 8 is arranged at the middle part of sealing head 7, and detonating wire 202 is arranged in the leading wire hole 8, and detonating wire 202 is connected with heating wire 9 two ends.

Embodiment 2

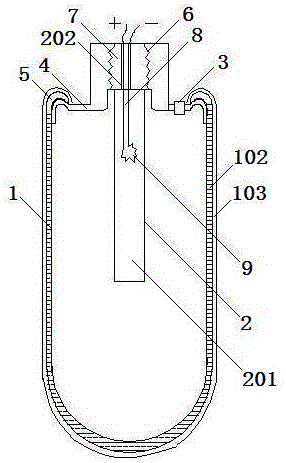

[0117] A gas blaster, comprising an energy storage device 1 and an energy discharge head 4, and one end of the energy storage device 1 is equipped with an energy discharge head 4;

[0118] like figure 2 As shown, the energy storage device 1 includes a mesh layer 102 and a hardened layer 103, and the mesh layer 102 and the hardened layer 103 are distributed sequentially from the inside to the outside.

Embodiment 3

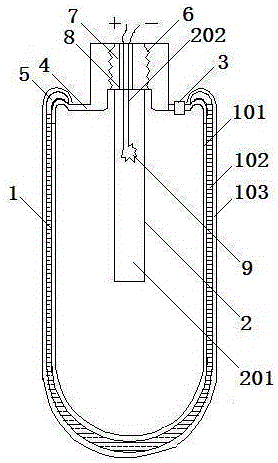

[0120] like image 3 As shown, the energy storage device 1 includes a base layer 101 , a mesh layer 102 and a hardened layer 103 , and the base layer 101 , the mesh layer 102 and the hardened layer 103 are distributed sequentially from inside to outside.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com