Improved steel anti-burning tank

A section steel and steel technology, applied in the field of foam fire extinguishing agent performance testing equipment, can solve problems such as different thicknesses and height differences, and achieve the effects of reducing errors, improving design, and accurate and reliable results of anti-burning experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

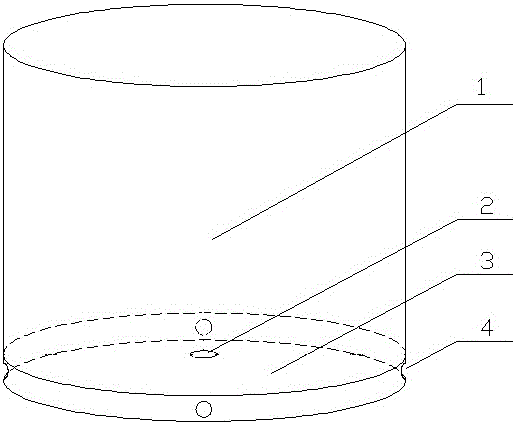

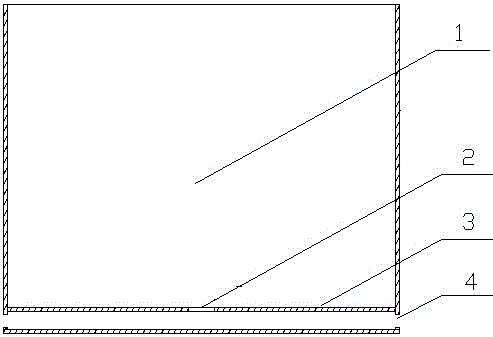

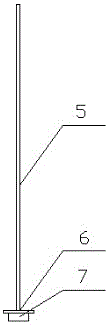

[0019] Such as figure 1 , figure 2 , image 3 As shown, the improved steel anti-scorching tank in this embodiment includes a steel anti-scorching tank body 1, an intermediate partition 3 is arranged at the bottom of the steel anti-scorching tank body 1, and a partition is opened in the middle of the intermediate partition 3. The plate through hole 2 and the partition through hole 2 are provided with a sealing plug. The sealing plug includes a sealing plug handle 5, a plastic pad 6 and a rubber stopper 7 fixedly connected in sequence. The diameter of the rubber plug 7 is the same as that of the partition through hole 2, and the plastic The diameter of the pad 6 is larger than that of the rubber stopper 7, and four external communication holes 4 are arranged on the outer wall of the anti-scorching tank between the bottom plate of the steel anti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com