Power connector

A connector and power technology, which is applied in the connection/disconnection of connecting devices, equipment for connecting/terminating cables, and connections where permanent deformation works. To achieve the effect of quick installation, improved work efficiency and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

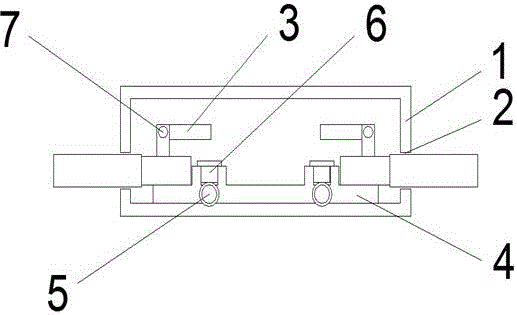

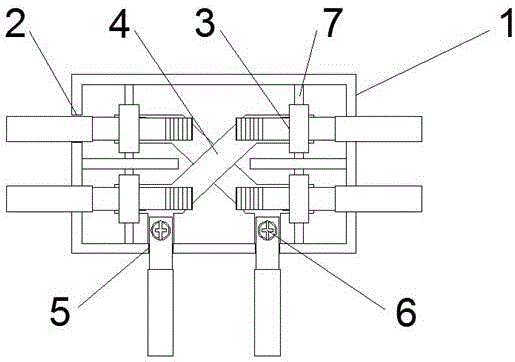

[0014] Such as Figure 1-2 As shown, a power connector includes a main body 1. The main body 1 is provided with a wire inlet 2, a wire clamp 3 and a connecting iron piece 4. The wire inlet 2 is arranged on the left and right sides of the main body 1, and the wire clamp 3 passes through The rotating shaft 7 is installed on both sides inside the main body 1, the connecting iron sheet 4 is arranged below the crimping buckle 3, the lower end of the connecting iron sheet 4 is provided with a split line interface 5, and the top of the split line interface 5 is threadedly provided with a set screw 6.

[0015] Specific use method: when wiring, insert the wire into the wire inlet 2, press the wire clamp 3 to press and fix the wire on the wiring iron piece 4, when connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com