Substrate and circuit board

A technology of circuit boards and substrates, which is applied to printed circuit components, circuit inspection/recognition, etc., can solve the problems of fading graphics, blurred positioning marks, and inability to provide references for electronic component deployment, so as to improve production levels and avoid The effect of inaccurate positioning and reducing production loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

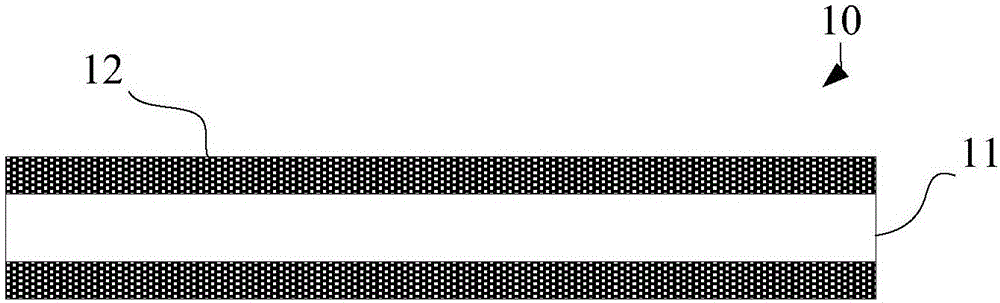

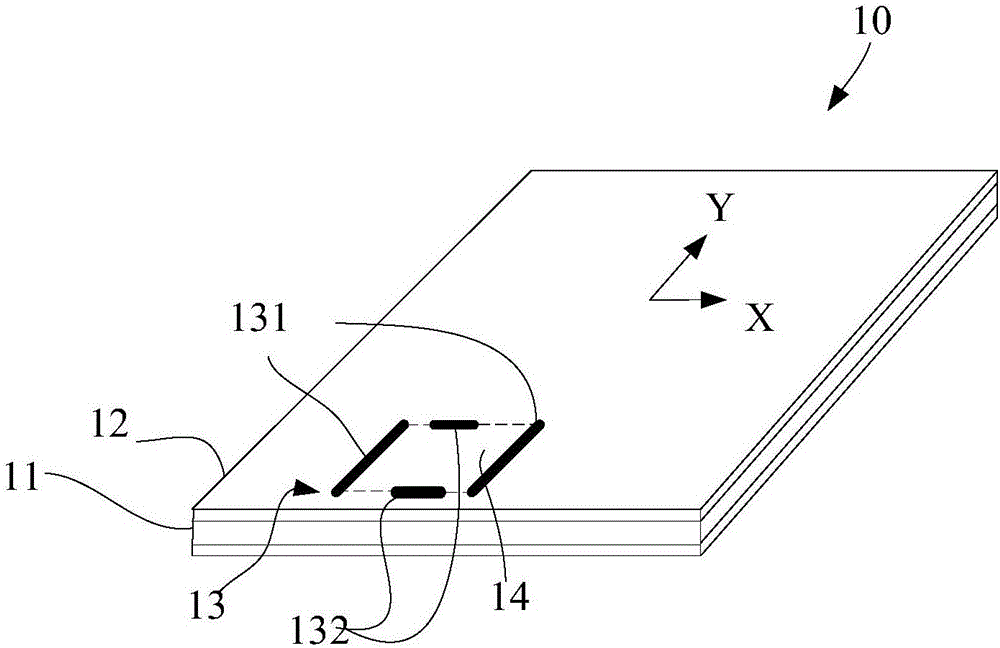

[0029] This embodiment provides a substrate, please refer to figure 1 , the substrate 10 includes a metal layer 11 and an ink layer 12 covering the surface of the metal layer 11 . Various types of electronic components can be deployed on the surface of the substrate 10 , such as capacitors, resistors, triodes, and other chip components that implement various functions. In order to locate certain components that need to be arranged on the substrate, positioning marks can be arranged on the surface of the substrate 10 .

[0030] The positioning mark in this embodiment is realized by etching the ink layer 12 on the metal layer 11 . Etching is the technique of removing material using chemical reaction or physical impact. Etching technology is a light-weight processing technology in PCB production, which can be divided into wet etching and dry etching. The basic principle is: the ink layer 12 is usually black or dark green. The metal layer 11 used in the substrate 10 is basical...

no. 2 example

[0042] This embodiment will continue to introduce the substrate and the circuit board including the substrate. In order for those skilled in the art to understand the advantages and details of the substrate and the circuit board in this embodiment more clearly, the following combined Figure 6 To elaborate:

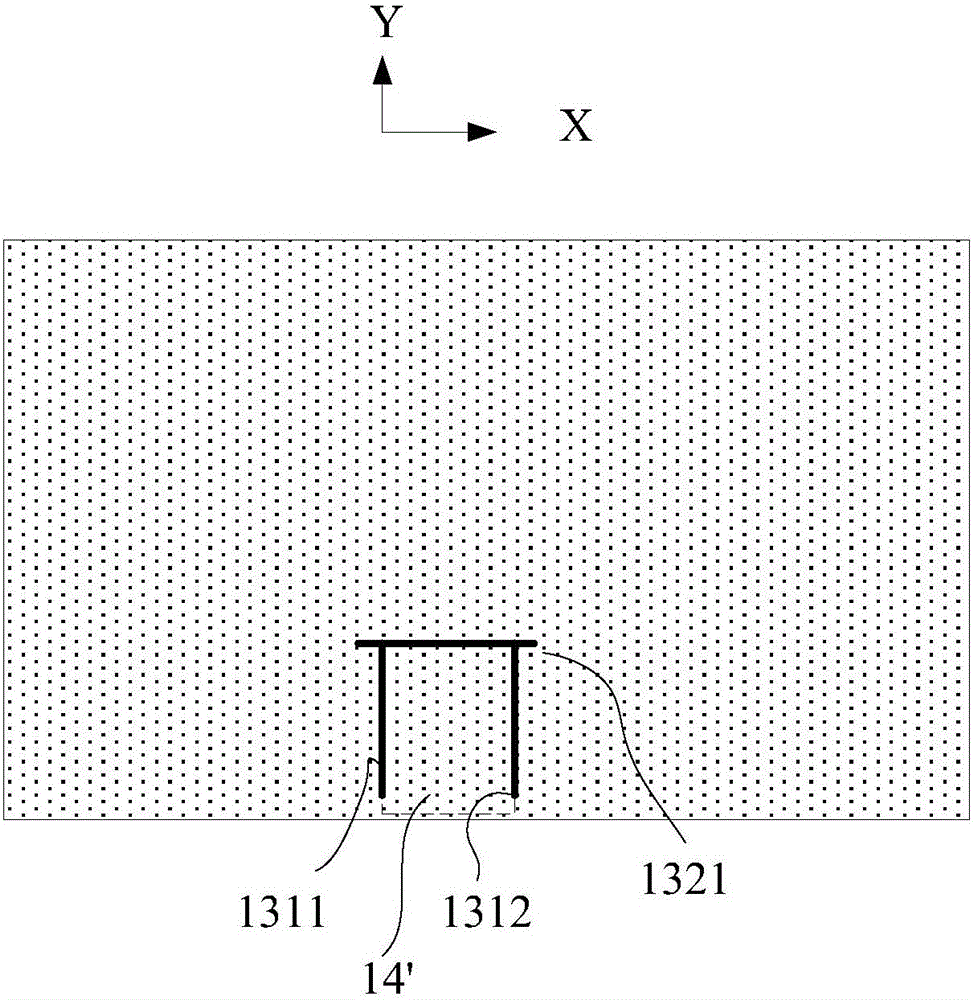

[0043] exist Figure 6 Among the substrates 60 provided, the positioning mark 63 arranged on the surface of the substrate still includes a first limit mark 631 for indicating the limit of the electronic component in the first direction, and a limit mark 631 for indicating that the electronic component is set in the second direction. Set the second limit mark 632 of the limit, and the first direction is perpendicular to the second direction. The first limit mark 631 is a line segment parallel to the second direction formed by etching the ink layer on the copper clad board; the second limit mark 632 is a line segment parallel to the first direction formed by etching the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com