Variable gap adjustment device

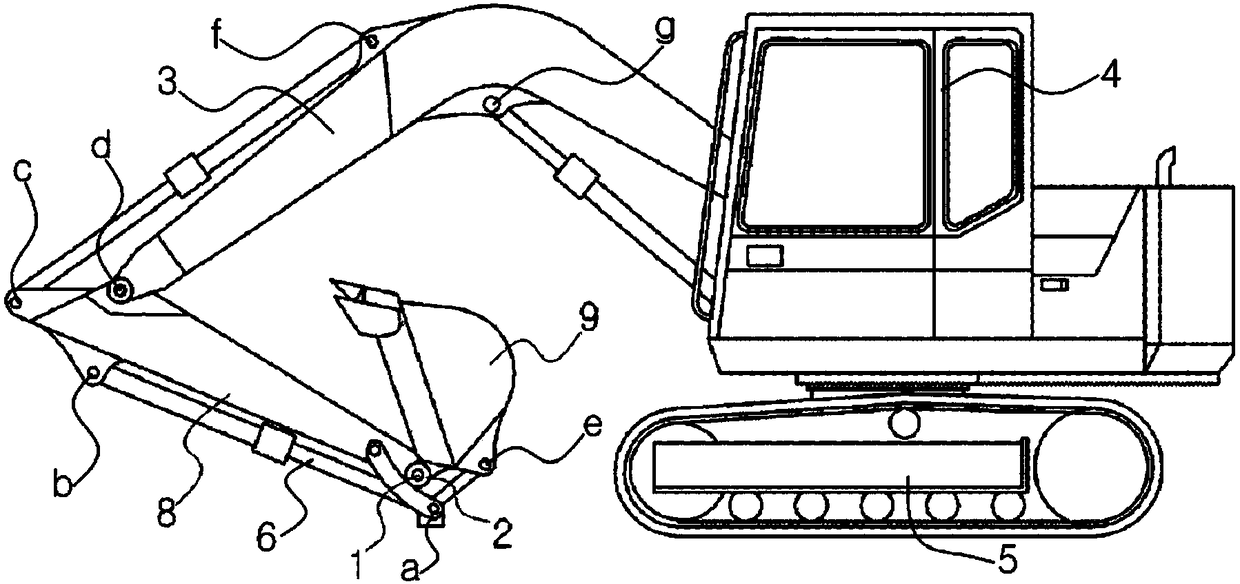

A gap adjustment device and variable technology, applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of time waste, excavator durability decline, burden, etc., achieve stable and strong support, and improve convenience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

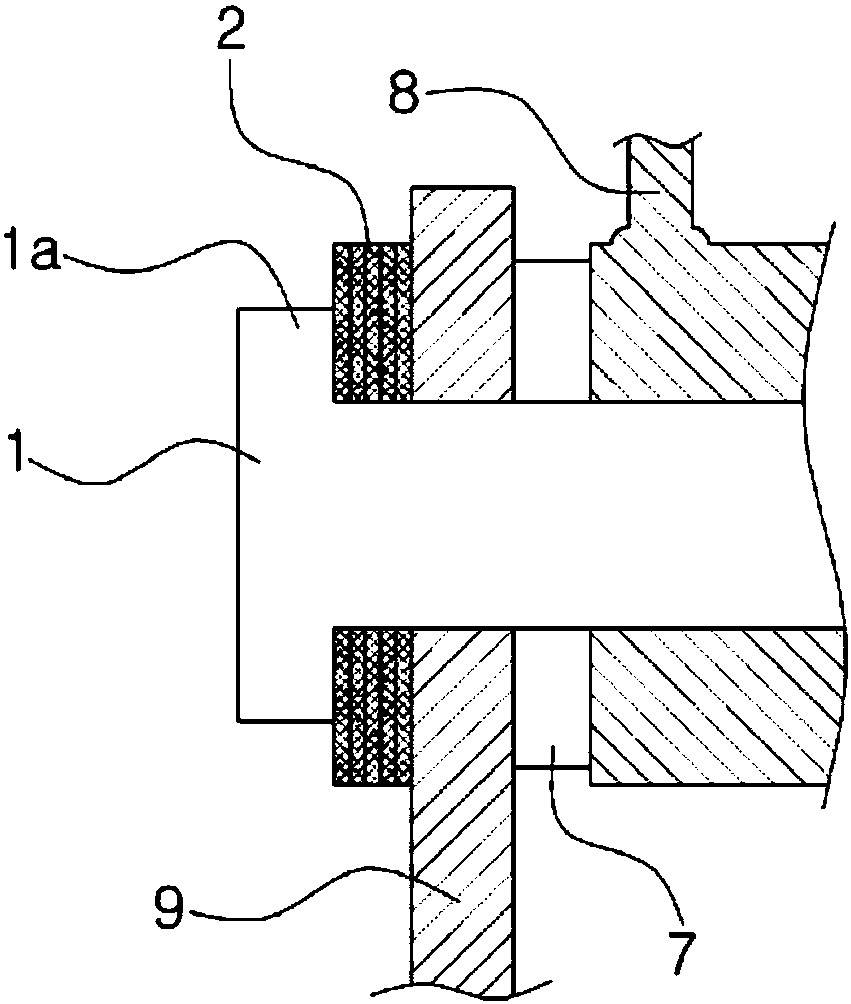

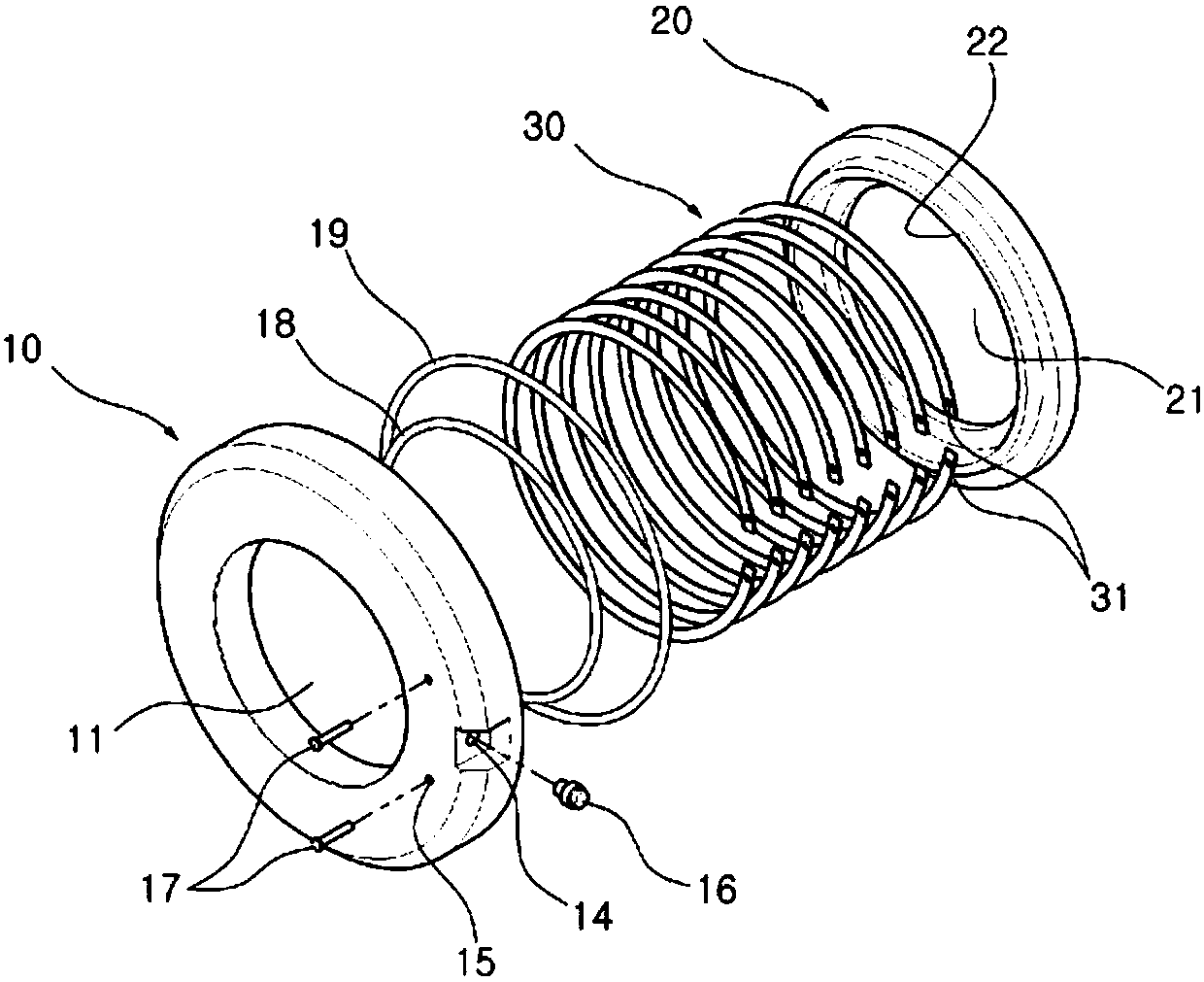

[0026] The best implementation form of the present invention will be described in detail in the following content with reference to the accompanying drawings.

[0027] In the following, the variable gap adjusting device applicable to the preferred embodiment of the present invention will be described in detail with reference to the accompanying drawings.

[0028] image 3 It is an exploded oblique view of a variable clearance adjusting device applicable to one embodiment of the present invention, Figure 4 and Figure 5 It is a schematic diagram of the connecting parts of the various structures of the variable gap adjusting device applicable to one embodiment of the present invention, Image 6 It is a schematic diagram of the combined state of the guide plate and the gap supporting snap ring to which one embodiment of the present invention is applied.

[0029] Such as Figure 3 to Figure 6 As shown, the variable gap adjustment device 100 applicable to the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com