Load platform for rock mechanical testing

A technology of rock mechanics and loading, applied in the field of rock mechanics testing, can solve the problems of mechanical damage of precision cable, high operation risk, load sensor damage, etc., to achieve the effect of preventing falling damage, supporting stable and strong, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention is described further as follows:

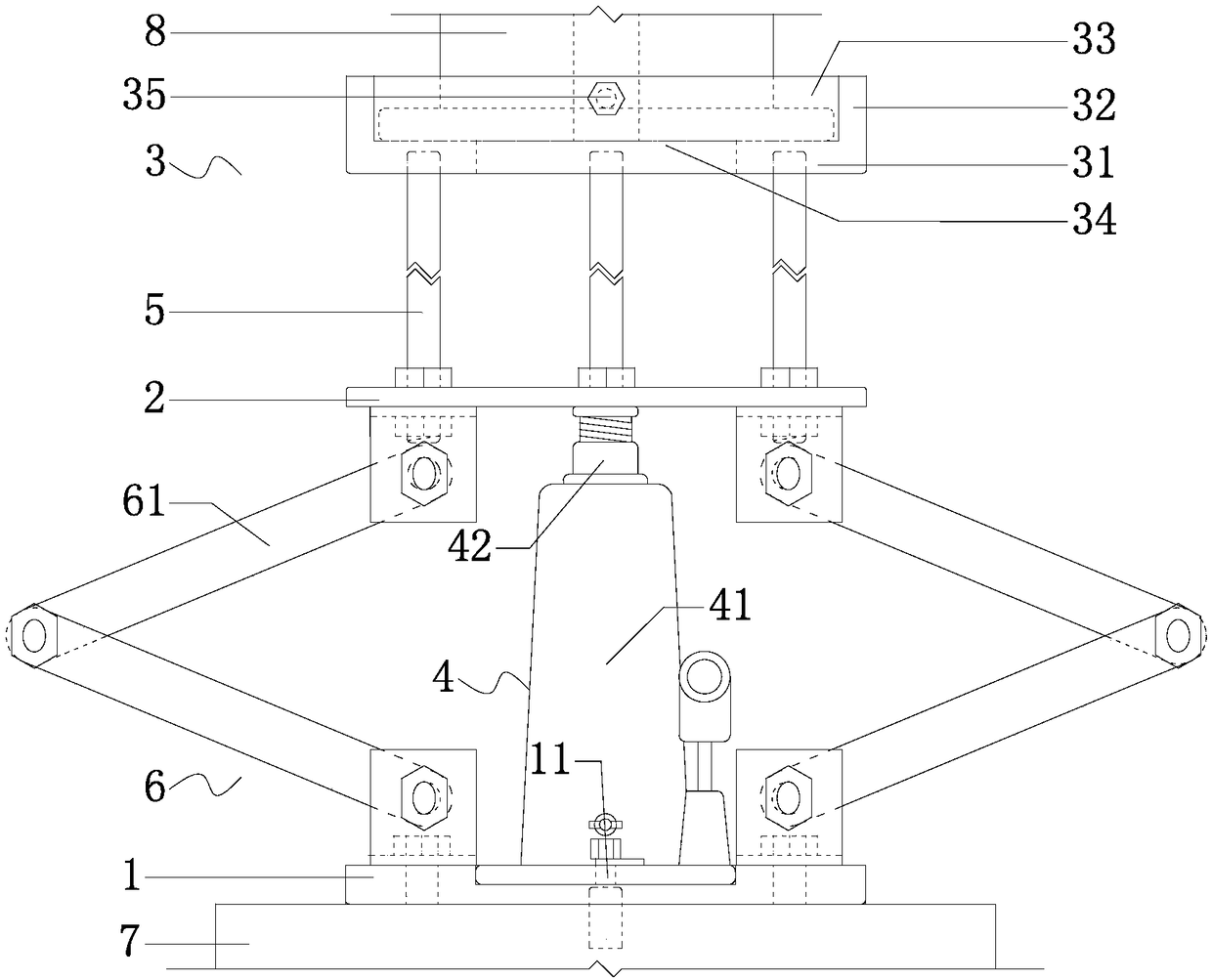

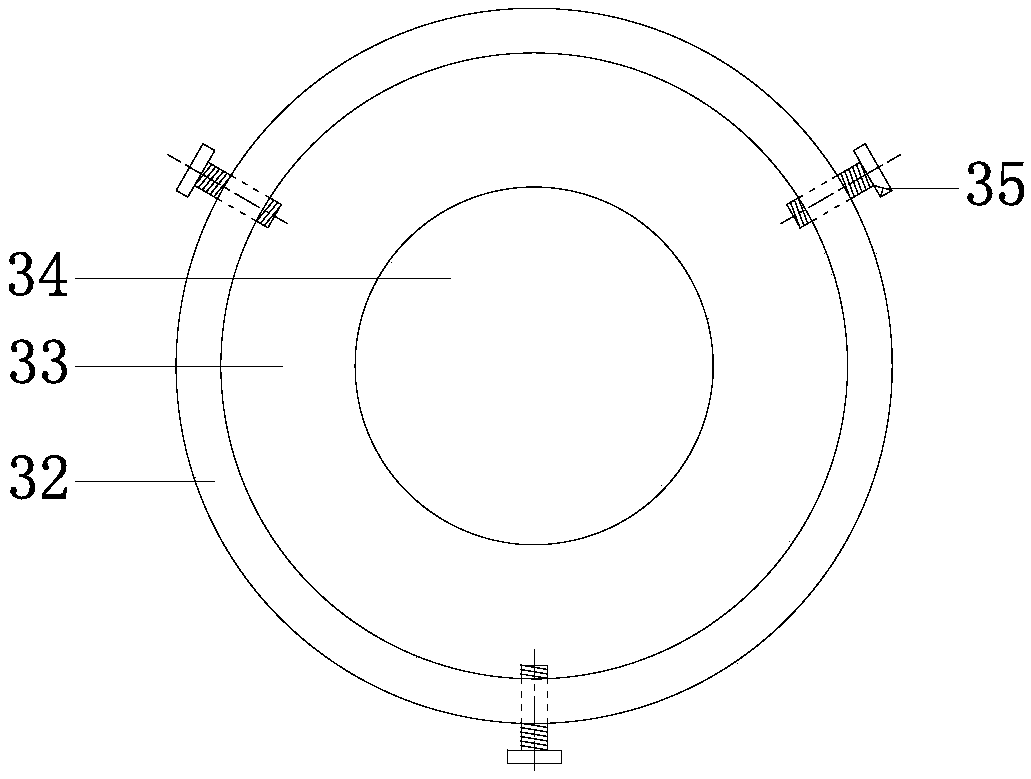

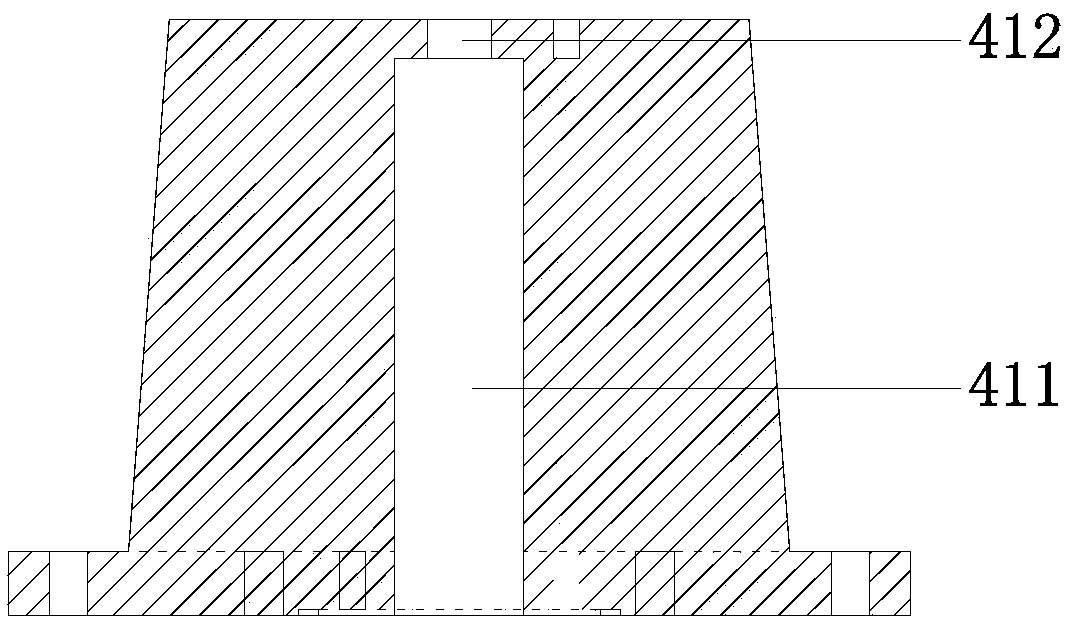

[0020] like figure 1 As shown, a load platform for rock mechanics testing includes a base 1, a lifting seat 3, and an intermediate connection seat 2 between the base 1 and the lifting seat 3; Assembly 4; the piston end of the hydraulic assembly 4 is connected to the bottom of the intermediate connecting seat 2, and the other end is connected to the base 1; the intermediate connecting seat 2 and the lifting seat 3 are connected through a set of connecting rods 5 The holding seat 3 includes a base plate 31 and a side wall 32 arranged on the base plate 31; surrounded by the side wall 32 and the base plate 31 to form an upward accommodating groove 33 for accommodating the MTS high temperature and high pressure sensor; The center of the bottom plate 31 of the lifting seat 3 is provided with an operation channel 34 passing through the bottom plate 31 along i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com