Pig-raising pigsty capable of automatically removing excrements

An automatic technology for raising pigs, which is applied in the field of agriculture and breeding, can solve the problems of pigs' stress effect, fat loss, etc., and achieve the effect of long service life, good strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

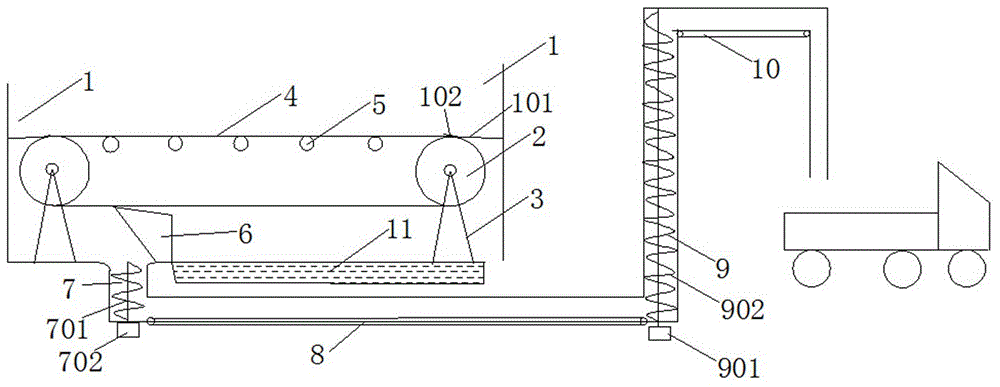

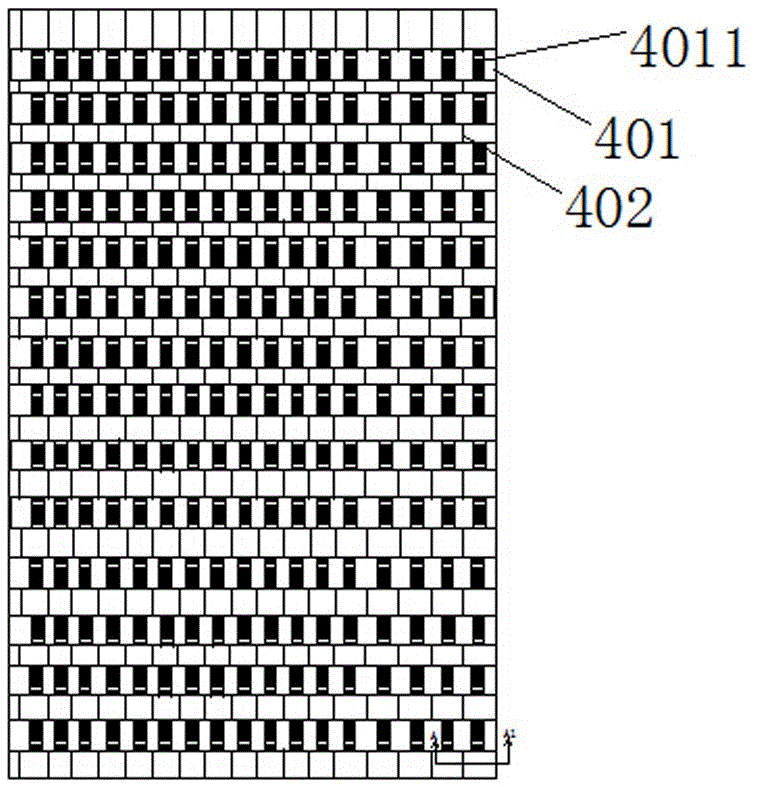

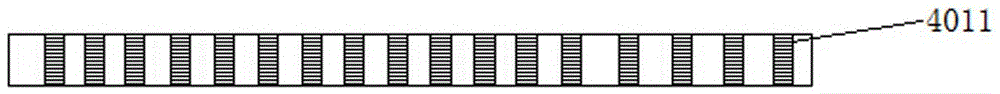

[0032] Specific embodiment 1: as Figure 1-5 As shown, the present invention discloses a pigpen that can automatically remove manure, including a fence 1 and a transmission shaft 2. The transmission shaft 2 is located on the inner side of the fence, and a bracket 3 is arranged below the transmission shaft 2 to fix the transmission shaft. The transmission shaft Connected to the power supply, the transmission shafts are two, and the two transmission shafts are provided with a moving bottom plate 4, the moving bottom plate 4 can rotate around the transmission shaft, and the inside of the moving bottom plate is provided with a support rod 5 for supporting the transmission bottom plate ;

[0033] The lower end of the movable base plate is fixed with a defecation baffle plate 6 for removing feces on the movable base plate, and the lower end of the junction between the movable base plate and the feces removal baffle plate 6 is provided with a channel, and the channel is provided with...

specific Embodiment 2

[0044] Specific embodiment 2: as Figure 1-5 As shown, the present invention discloses a pigpen that can automatically remove manure, including a fence 1 and a transmission shaft 2. The transmission shaft 2 is located on the inside of the fence, and a bracket 3 is arranged below the transmission shaft 2 to fix the transmission shaft. The transmission shaft Connected to the power supply, the transmission shafts are two, and the two transmission shafts are provided with a movable base plate 4, the movable base plate 4 can rotate around the transmission shaft, and the inside of the movable base plate is provided with a support rod 5 for supporting the transmission base plate ;

[0045] The lower end of the movable base plate is fixed with a defecation baffle plate 6 for removing feces on the movable base plate, and the lower end of the junction between the movable base plate and the feces removal baffle plate 6 is provided with a channel, and the channel is provided with a descen...

specific Embodiment 3

[0056] Specific embodiment 3: as Figure 1-5 As shown, the present invention discloses a pigpen that can automatically remove manure, including a fence 1 and a transmission shaft 2. The transmission shaft 2 is located on the inner side of the fence, and a bracket 3 is arranged below the transmission shaft 2 to fix the transmission shaft. The transmission shaft Connected to the power supply, the transmission shafts are two, and the two transmission shafts are provided with a moving bottom plate 4, the moving bottom plate 4 can rotate around the transmission shaft, and the inside of the moving bottom plate is provided with a support rod 5 for supporting the transmission bottom plate ;

[0057] The lower end of the movable base plate is fixed with a defecation baffle plate 6 for removing feces on the movable base plate, and the lower end of the junction between the movable base plate and the feces removal baffle plate 6 is provided with a channel, and the channel is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com