A shading method and shading panel body

A coloring and panel technology, applied in the field of coloring, can solve the problems of affecting the coloring effect of the panel body, poor coloring effect of the panel body, poor coloring effect, etc., achieve good coloring effect and quality, improve coloring quality, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

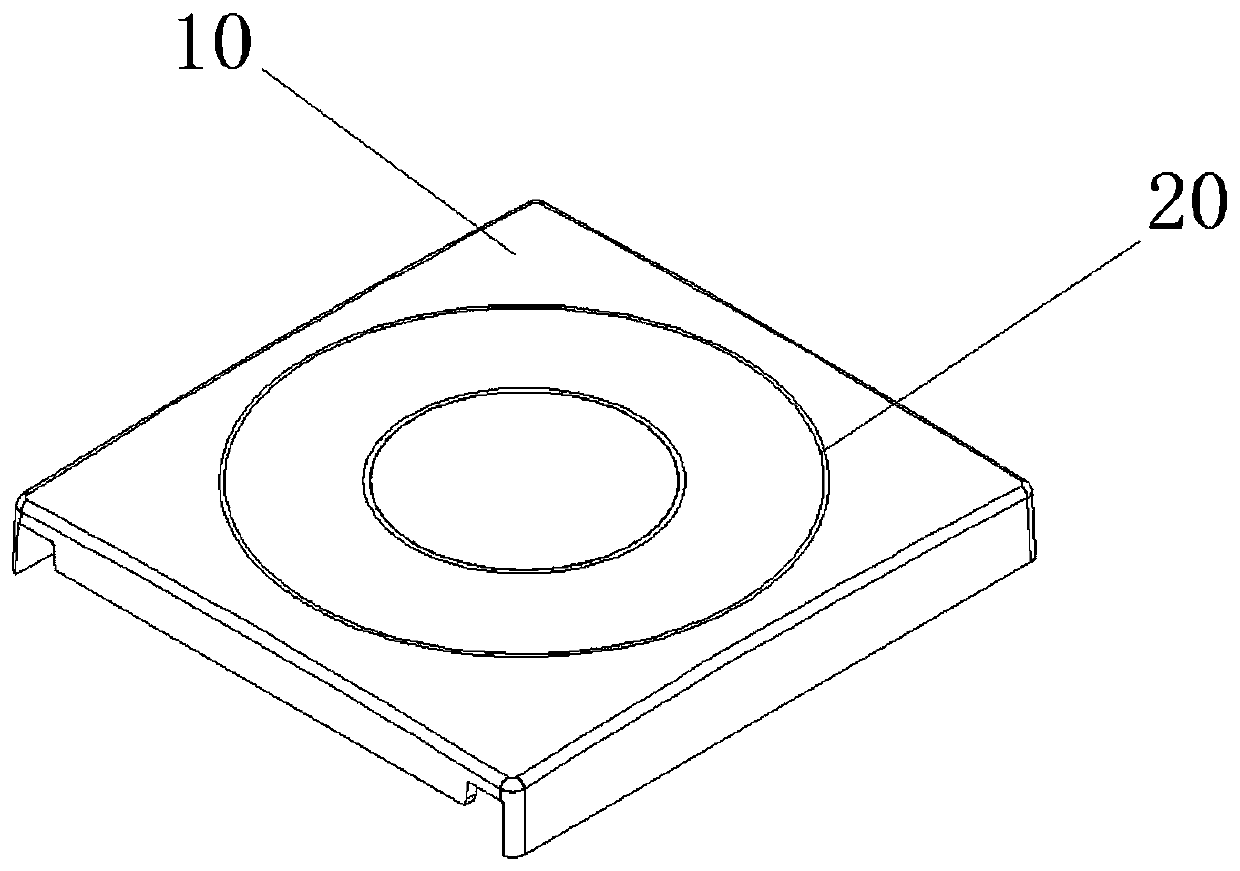

[0024] The following will be combined with Figures 1 to 5 The specific embodiment of the present invention is described in detail:

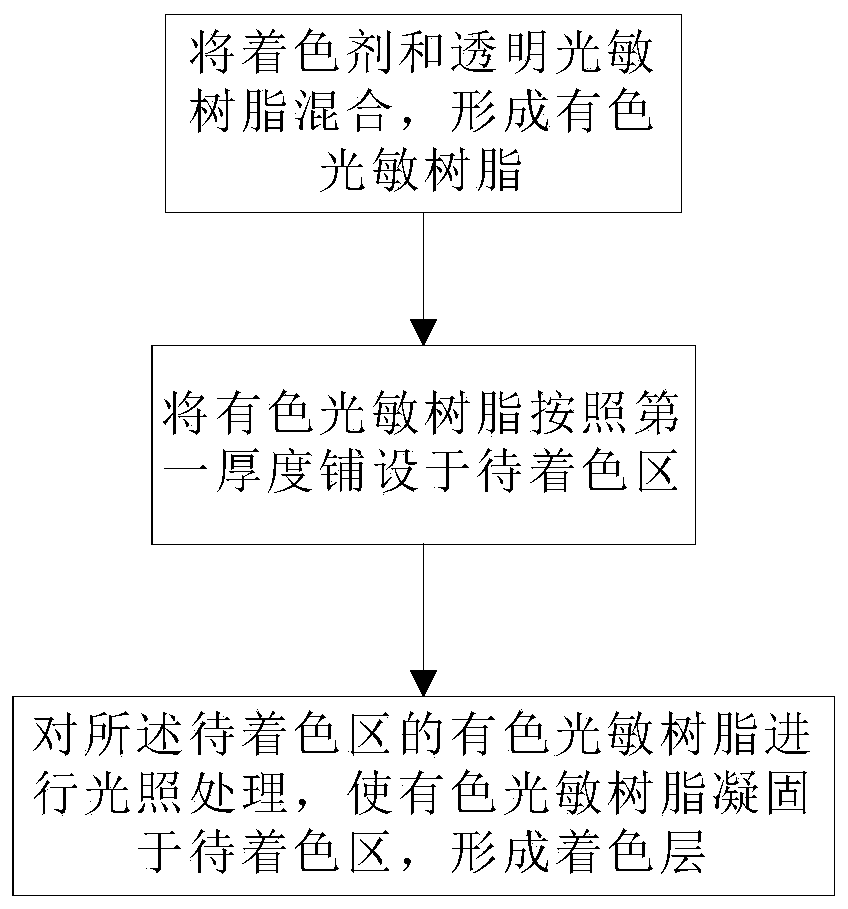

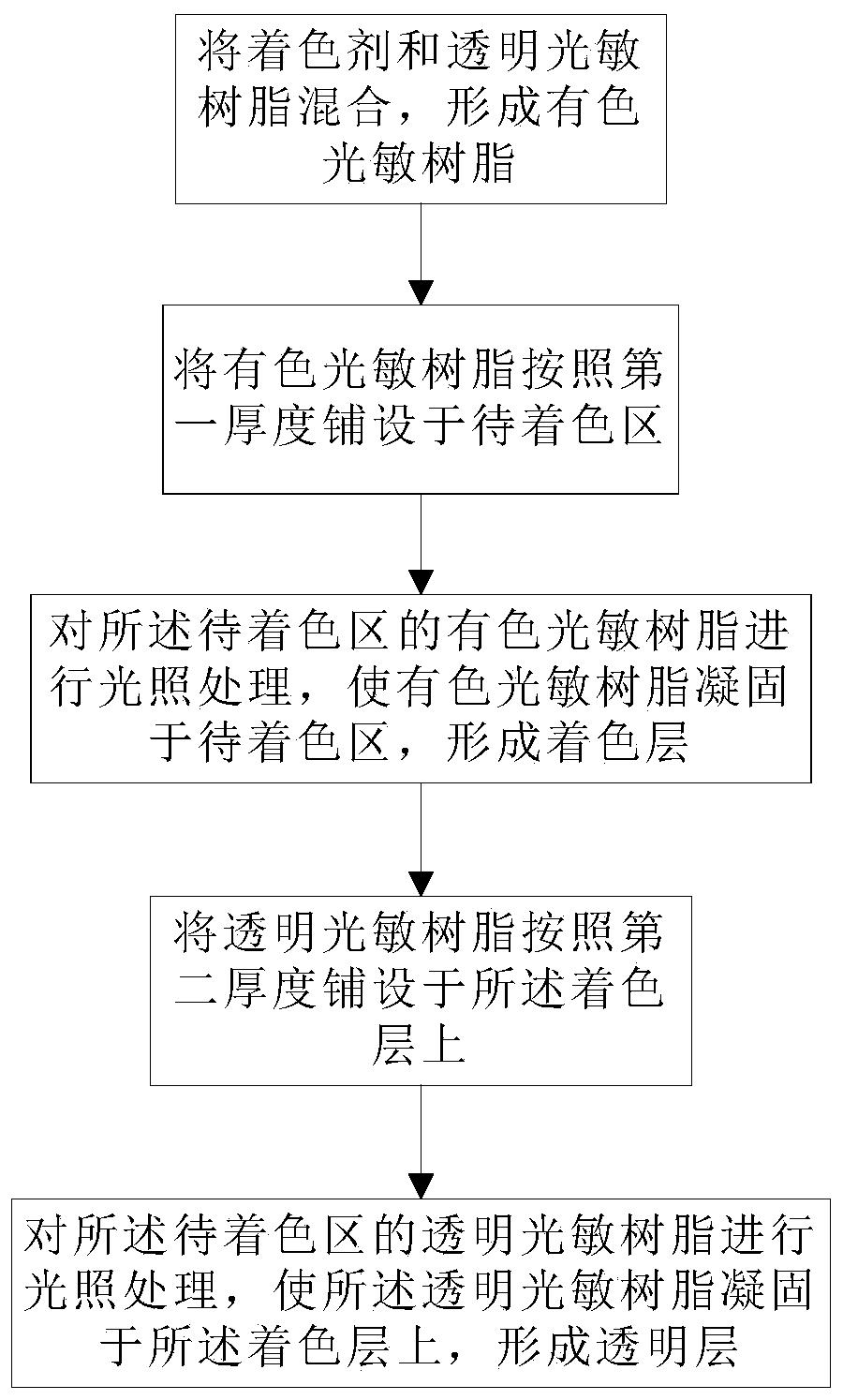

[0025] like figure 1 As shown in the flow chart, the coloring method includes the following steps: mixing the colorant and the transparent photosensitive resin to form a colored photosensitive resin; laying the colored photosensitive resin on the area to be colored 20 according to the first thickness; The colored photosensitive resin is subjected to light treatment, so that the colored photosensitive resin is solidified in the area to be colored 20 to form the colored layer 21 . Wherein, the first thickness is less than or equal to the first curing depth, and the first curing depth is the distance at which light perpendicular to the surface of the colored photosensitive resin penetrates into the colored photosensitive resin and cures the colored photosensitive resin. This method adopts the photosensitive resin mixed with the coloring agent, wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com