Cleaning device

A technology for cleaning devices and mounting holes, which is applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as obstacles to the production and manufacturing efficiency of circuit boards, low cleaning efficiency, etc., and saves time for water changes. , Improve the effect of cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

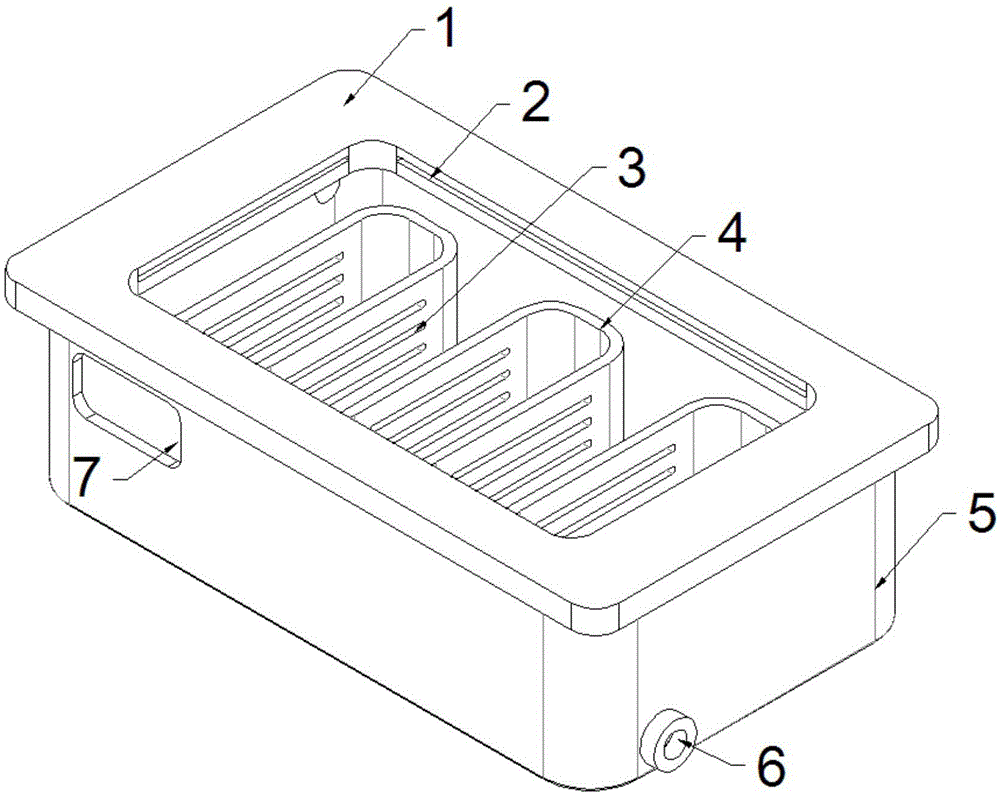

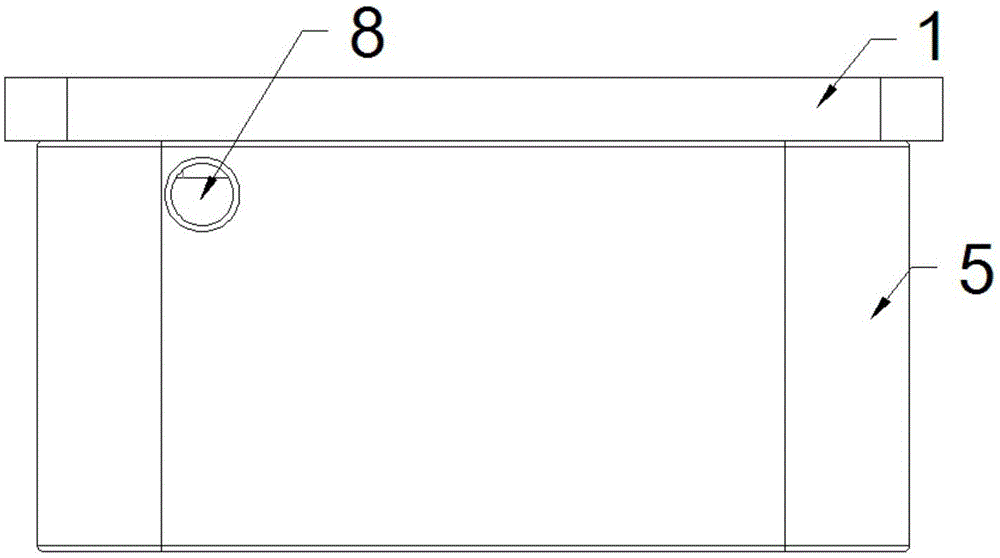

[0021] Such as Figure 1-2 As shown, a cleaning device includes a cover 1 and a body 5, and the cover 1 is fixedly connected to the body 5. The cover 1 is a closed frame, and the inside of the frame is provided with a glass installation hole 2 for installing a glass lens. This design is to make it convenient for the staff to observe the cleaning status of the circuit board inside the body 5 in real time. A bracket 4 is mounted on the bottom of the body 5 , and a socket 3 for installing the circuit board is provided on the side of the bracket 4 . This design effectively avoids the disadvantage of simply stacking the circuit boards in the cleaning device, resulting in less water on the surface of the circuit boards and not being able to clean them thoroughly. Because of this, this design effectively improves the cleaning efficiency of the cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com