An iron tower positioning platform

A positioning platform and iron tower technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of potential safety hazards, prolonging the welding construction period, wasting manpower, etc., to shorten the construction period, avoid safety hazards, Easy to adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

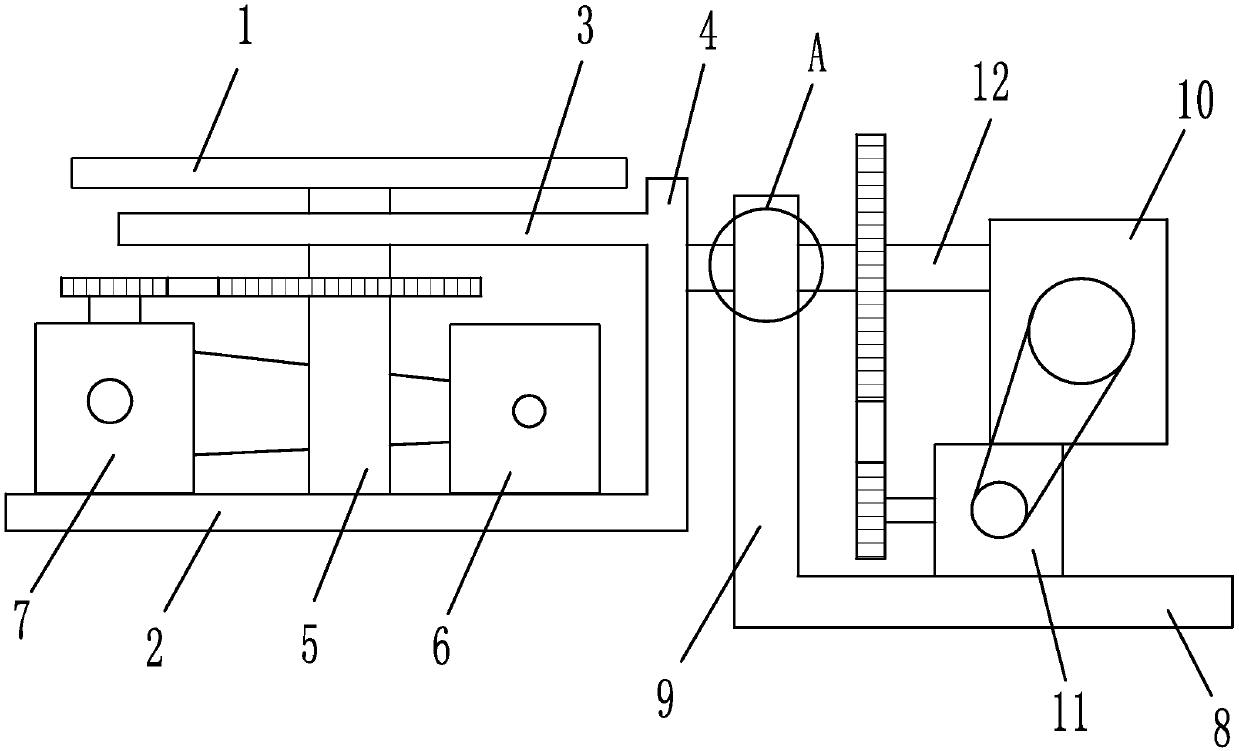

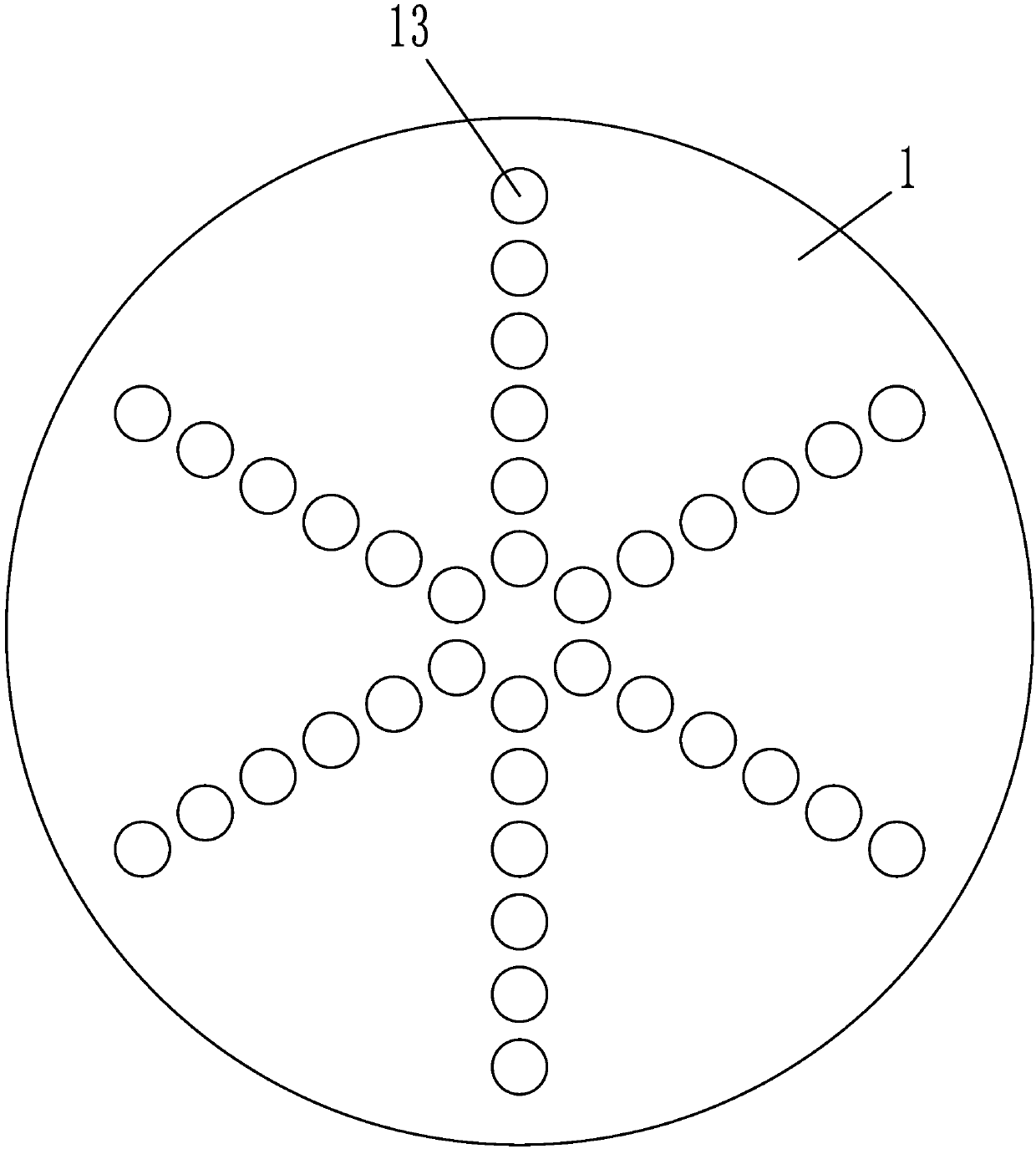

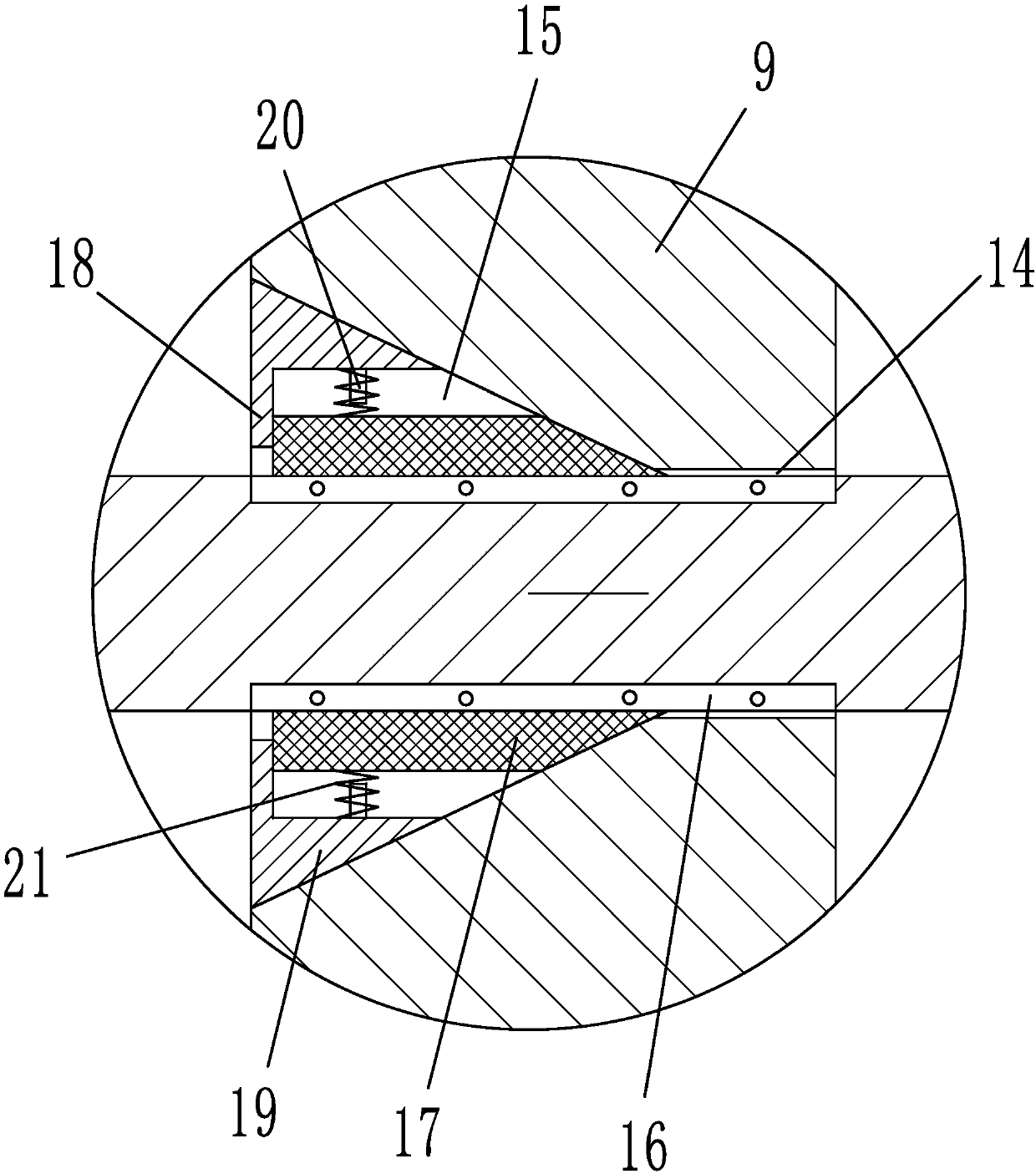

[0017] Embodiment 1: as figure 1 As shown, a kind of iron tower positioning platform, comprises platform and frame, and platform comprises platform and fixed frame, and platen 1 and fixed frame are rotatably connected by the driving rotating shaft 5 that vertically arranges, and the fixed frame is provided with first motor 6 and the first reduction box 7 connected with the first motor, the first reduction box is connected with the drive shaft through a sprocket. The frame and the fixed frame are rotationally connected by a horizontal turning shaft 12. The frame is provided with a second motor 10 and a second reduction box 11 connected to the second motor. The second reduction box is connected with the turning shaft by a sprocket. The frame is in an "L" shape, and the frame includes a base plate 8 and a vertical plate 9, and the turning shaft runs through the vertical plate horizontally. The fixed frame includes a horizontal support plate 2, a horizontal positioning plate 3 po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com