Bolt underwater dissembling and assembling tool

A technology for bolts and tools, which is applied in the field of underwater disassembly and assembly of bolts and storage tools. It can solve the problems that disassembly and installation tools cannot meet the requirements of underwater long-distance disassembly and installation, and achieve reliable bolt disassembly and assembly work, simple structure, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

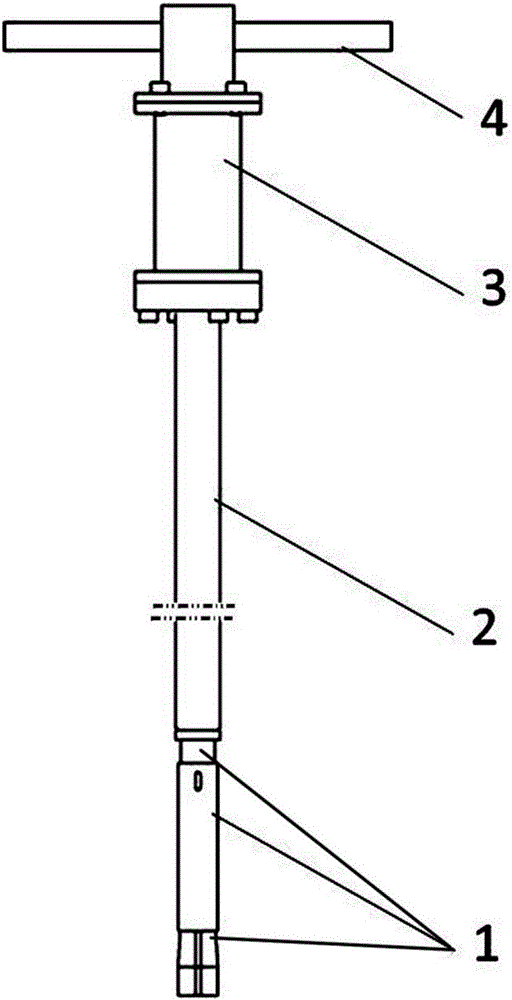

[0030] Bolt underwater disassembly tools, such as figure 1 As shown, it includes an operating rod, an elastic grab head 1, a handle 4 and a driving device.

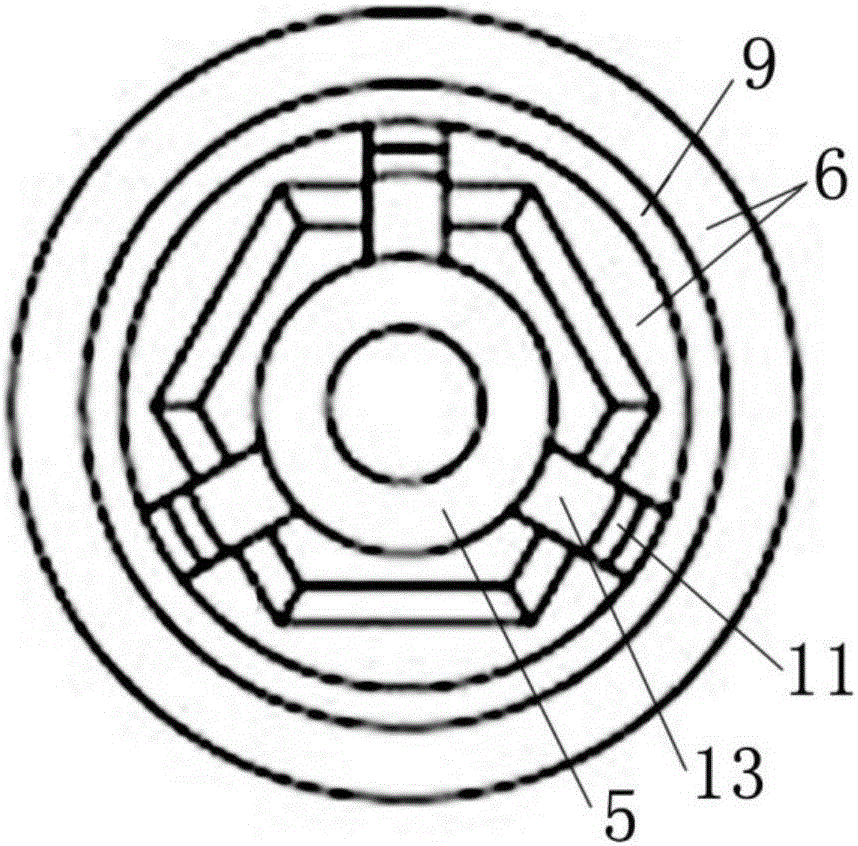

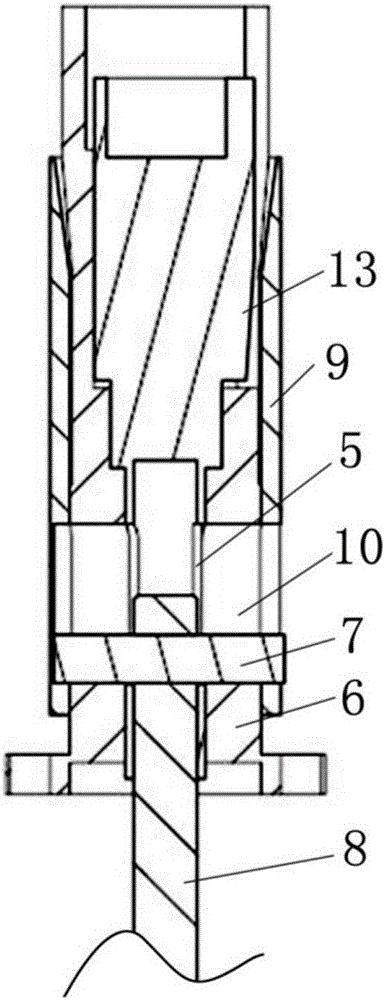

[0031] The elastic grab head 1, such as figure 2 with image 3 As shown, it includes an elastic sleeve 6 made of precipitation hardening stainless steel, and a locking sleeve 9 sleeved on the elastic sleeve 6. The front end of the elastic sleeve 6 is provided with three squeezing through grooves 11 distributed at 120° in the circumferential direction to facilitate the compression of the locking sleeve 9. The locking sleeve 9 cooperates with the elastic sleeve 6 and can slide on the elastic sleeve 6. The anti-rotation pin 7 is connected with the locking sleeve 9 and the moving rod 8 as a whole, and the anti-rotation pin 7 can pass through the sliding slot 10 in The elastic sleeve 6 slides on.

[0032] When the locking sleeve 9 moves upward, the elastic sleeve 6 is opened; when the locking sleeve 9 moves downward, the elastic ...

Embodiment 2

[0043] The difference between this embodiment and embodiment 1 is that this embodiment adds an anti-torsion device, such as Figure 4 As shown, the specific settings are as follows:

[0044] The anti-torsion device is arranged in the elastic sleeve 6 and welded together with the elastic sleeve 6. The anti-torsion device includes a connecting sleeve 5 and a prismatic tooth 13, and the rear end of the connecting sleeve 5 is provided with a connecting through groove 12 and a connecting through groove 12 It corresponds to the sliding through groove 10. The front end of the connecting sleeve 5 is provided with prismatic teeth 13, the number of the prismatic teeth 13 is set to three, and the three prismatic teeth 13 are respectively clamped into the three extrusion through grooves 11 of the elastic sleeve 6. The anti-torsion device A hexagonal prism 14 is arranged in the middle of the, the hexagonal prism 14 is matched with the hexagonal hole of the elastic sleeve 6, and the moving rod...

Embodiment 3

[0047] The difference between this embodiment and Embodiment 2 is that, in order to be better suited for the disassembly and installation of underwater bolts or nuts, during the use of the present invention, it is also located at a position adjacent to the disassembly and installation of bolts or nuts. Set up new and old bolt storage containers, such as Figure 5 As shown, the new and old bolt storage container is plate-shaped, and a plurality of bolt connection holes and nut connecting rods are provided on the new and old bolt storage container.

[0048] When in use, you can first install a new nut on the nut connecting rod, then install the new bolt on the bolt connecting hole, and then place it at the position where the bolt and nut need to be replaced. After the nut or bolt is disassembled by the tool of the present invention, the disassembled nut or bolt is installed on the new and old bolt storage container, and then the new bolt and nut are removed from the old and new bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com