Ejection system and operation method thereof

An ejection system and an ejection technology, applied in the field of ejection systems, can solve the problems that the burr 1 of the bump hole cannot be completely repaired, affects the output, and delays time, etc., so as to solve the problem of flashing on the bump surface, improve the pressing condition, Effect of improving mold life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

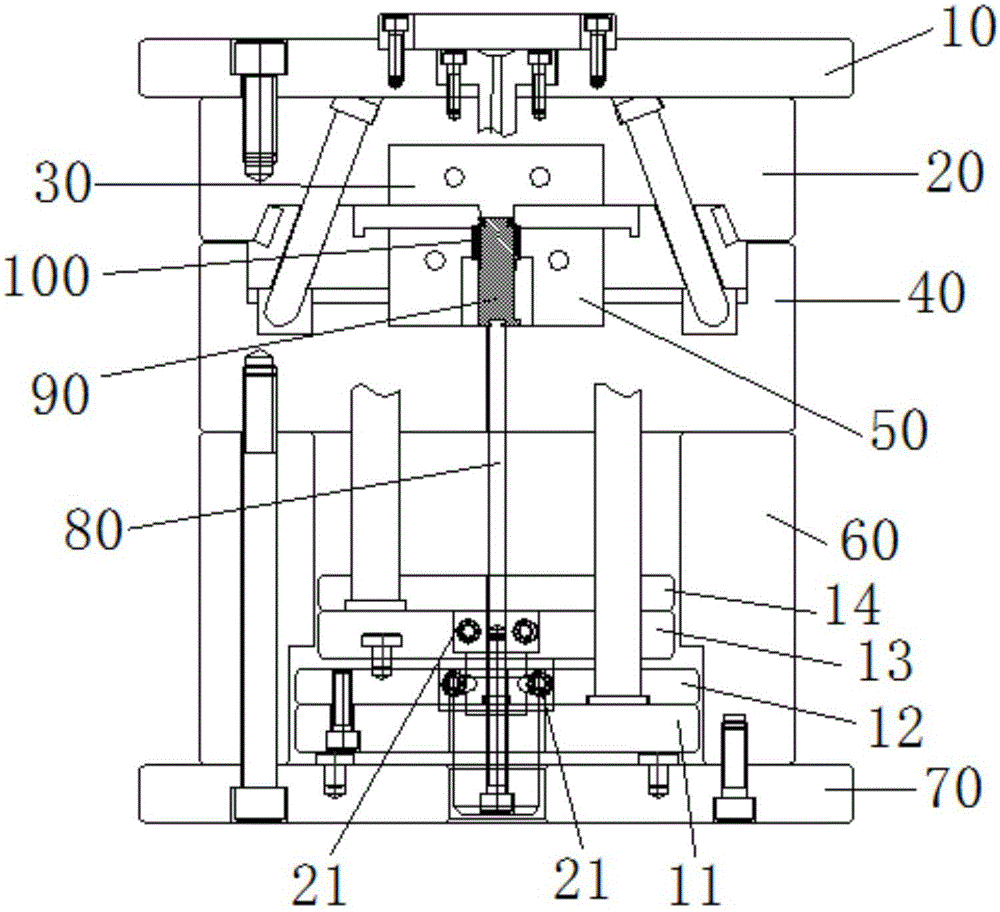

[0020] figure 2 is an overall schematic diagram of the ejection system according to a preferred embodiment of the present invention.

[0021] Such as figure 2 As shown, the ejection system according to a preferred embodiment of the present invention includes: an upper fixed plate 10, a front template 20 fixed below the upper fixed plate 10, a front mold core 30 fixed in the front template 20, a lower fixed plate 70, a fixed The square iron 60 on the lower fixing plate 70, the back template 40 fixed on the square iron 60, and the back mold core 50 fixed in the back template 40.

[0022] Among them, a top stick groove is arranged through the lower fixing plate 70, the square iron 60, the back template 40 and the back mold core 50, and a top stick 80 is arranged in the top stick groove, and a top of the top stick 80 is arranged to prevent the product 100 to be ejected. The insert 90.

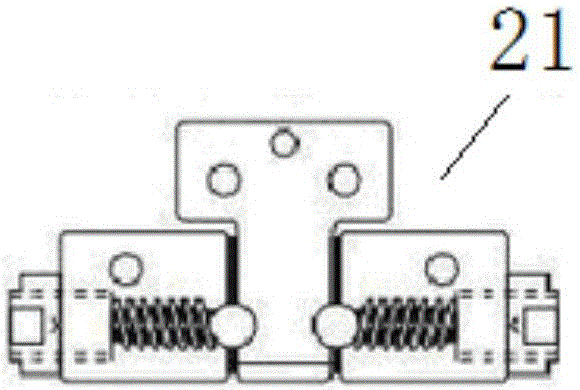

[0023] And wherein, the first ejector plate 11, the second ejector plate 12, the third eje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com