A method for jointing polyurethane belts and a high-frequency friction jointing tool

A tool, high-frequency technology, applied in the field of tools used for connection, can solve the problems of joint misalignment, poor temperature control, uneven connection surface, etc., to achieve the effect of increasing elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The essence of the method for butt jointing polyurethane round belts or triangular belts described in the present invention is to use the vibration and friction heating of the chuck to butt the two ends of the polyurethane. This is the difference between the present invention and the existing technology. Significant contributions made by technology. Invented a method for jointing polyurethane belts. A linear polyurethane belt is butted, the two ends of the polyurethane belt are butted together, and one of the ends is vibrated at high frequency to generate heat. Gradually lower to a stop, during which the polyurethane ends are fused together and then centered, thereby melting and butting the ends of the polyurethane band together.

[0031] The present invention will be further elaborated below in conjunction with accompanying drawing:

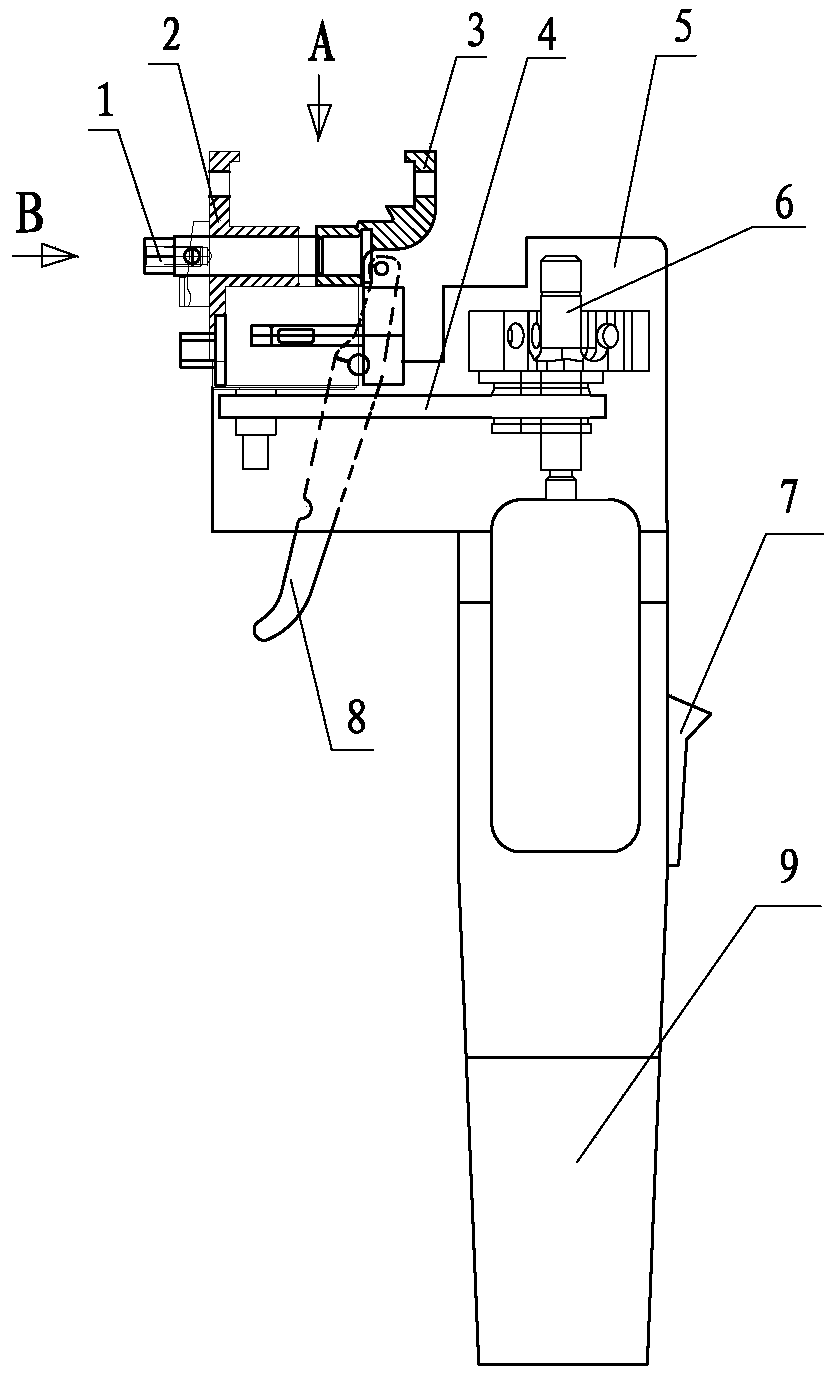

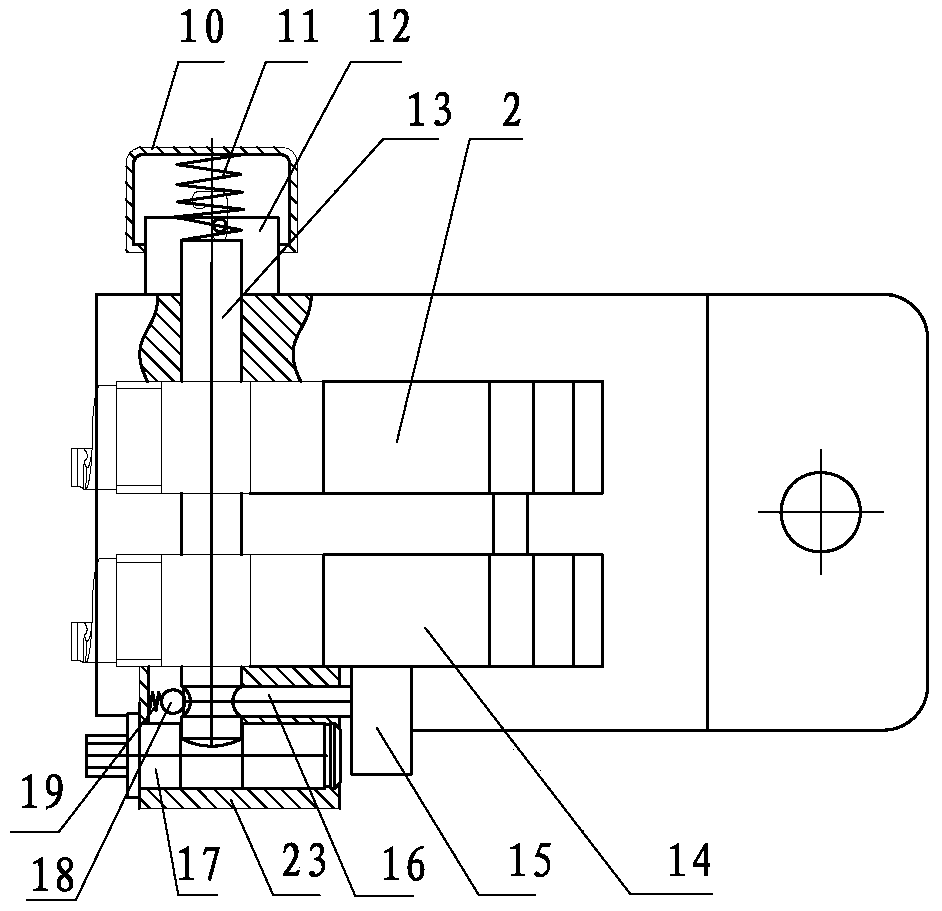

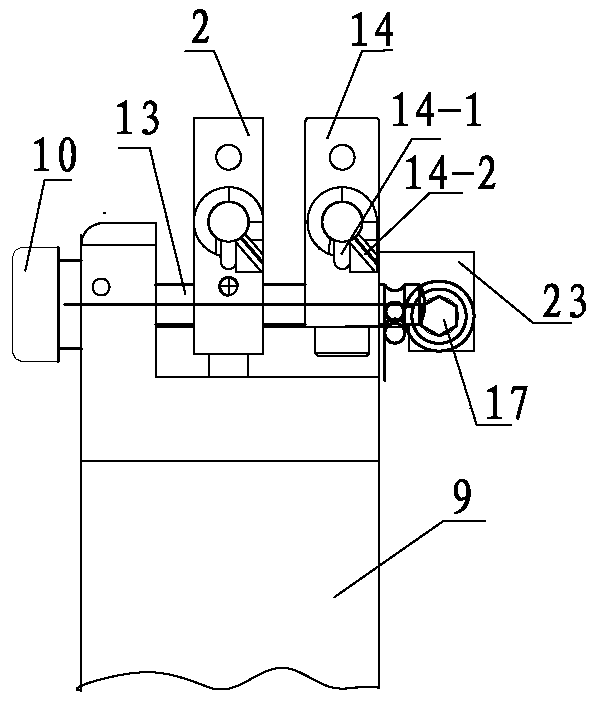

[0032]As shown in the figure, the high-frequency friction connection tool of the present invention includes a handle 9, the upper end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com