Film unwinding structure for digital film printing

A technology of digital printing and membrane structure, applied in printing devices, printing and other directions to achieve the effect of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

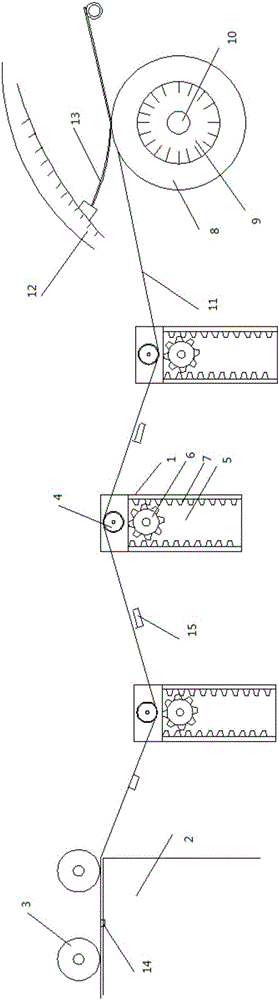

[0010] Referring to the accompanying drawings, a film release structure for film digital printing includes several side-by-side staggered high and low preload adjustment seats, a printing platform 2, and a pressure roller 3 is arranged on the printing platform 2. The preload adjustment seat includes a square Adjusting seat 1, the upper end of the adjusting seat 1 is equipped with a preload wheel 4, the lower part of the adjusting seat 1 is provided with a notch 5, the notch 5 is provided with a driving gear 6, and the two sides of the notch 5 are respectively provided with gears meshing with the driving gear 6. Rack 7; a code disc 9 is arranged coaxially with the film release wheel 8, and the film release wheel 8 is driven by a motor 10, and a film 11 is wound on the film release wheel 8, and the other end of the film 11 passes through the preload adjustment seat 1 in turn Pretensioner 4, pressure roller 3, code bar 12, arc code pin 13 are arranged on the top of code disc 9, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com