Compensation hole and center valve type brake master cylinder opening sealing structure

A technology of brake master cylinder and sealing structure, applied in the direction of brakes, brake transmissions, vehicle components, etc., can solve the problems of unstable movement performance, affecting sealing performance, short guiding distance, etc., to improve the sealing efficiency of products, use The effect of improved performance and long guiding distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

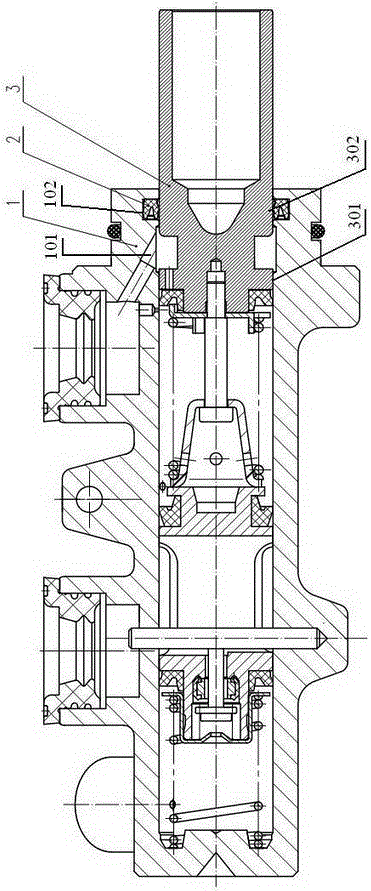

[0007] The inner end of the first piston 3 is slidingly connected with the master cylinder 1 through the first contact 301 and the second contact 302, and the oil inlet hole 101 of the master cylinder is located between the first contact 301 and the second contact 302. There is a sealing ring groove 102 on the main cylinder body that is slidingly connected with the second contact point 302 of the first piston 3 , the outer lip of the auxiliary cup 2 is in sealing connection with the sealing ring groove 102 , and the inner lip is connected with the second sealing ring groove of the first piston 3 . The outer diameters of the two contact parts 302 are sealed and connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com