Box turnover device

A flipping device, box technology, applied in the direction of packaging, transportation and packaging, conveyor objects, etc., can solve the problems of high production and maintenance costs, low production efficiency, lack of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

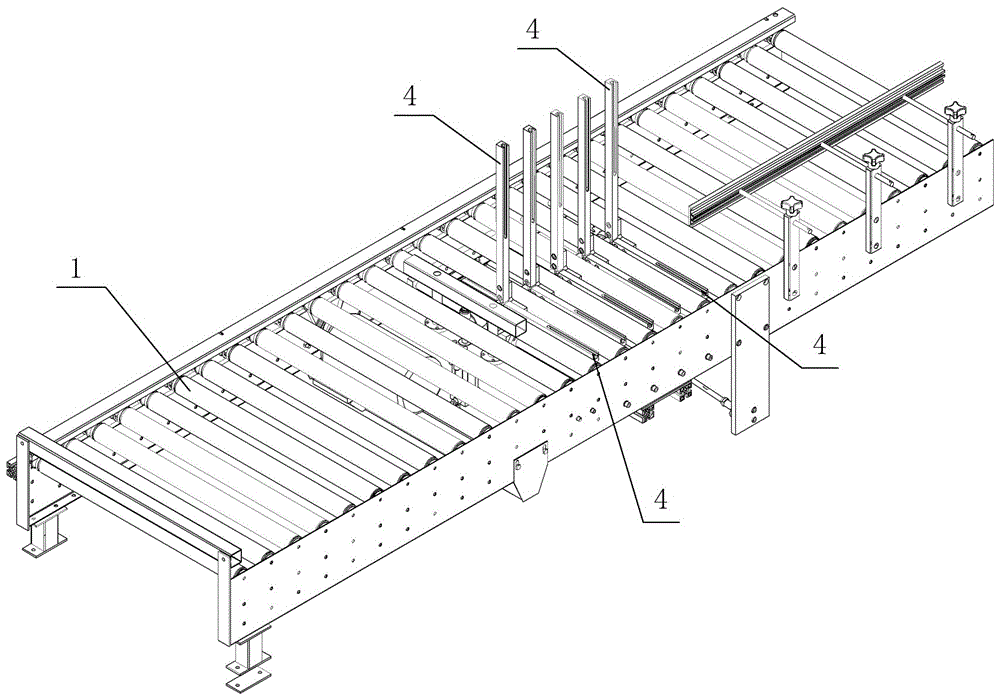

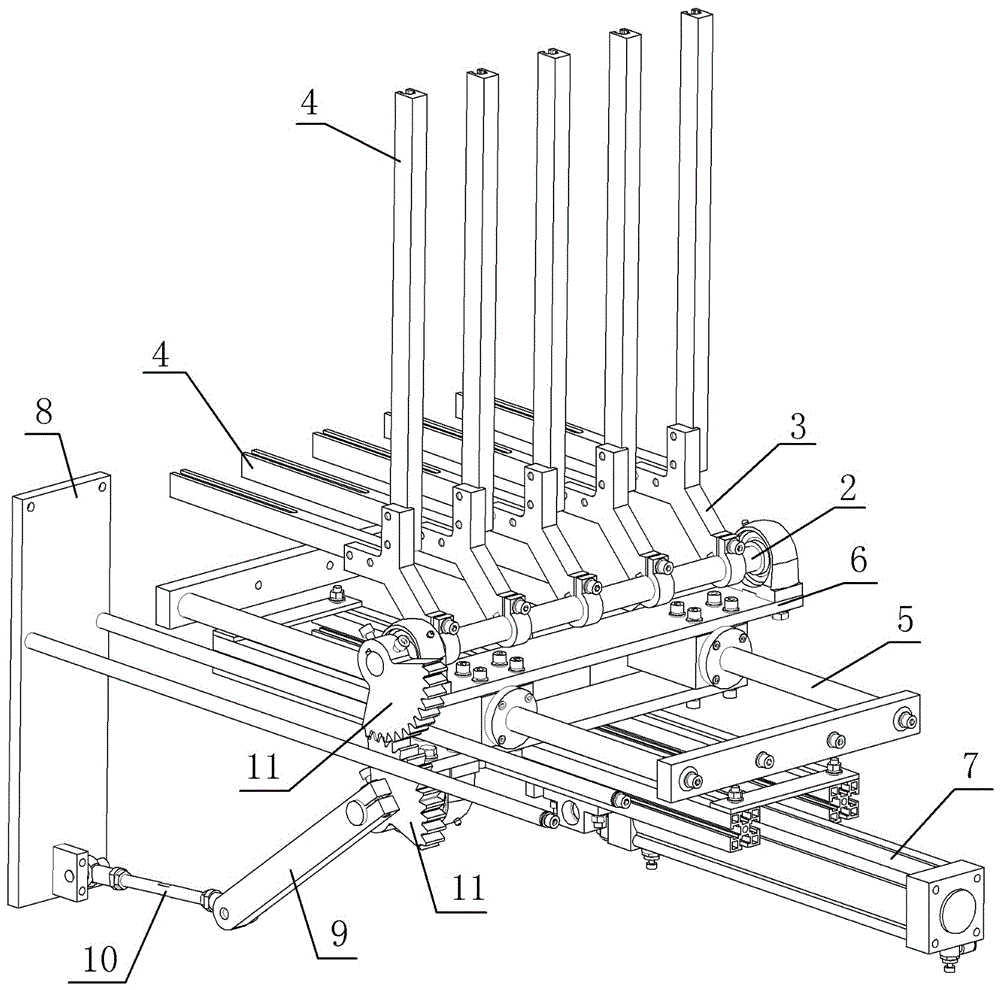

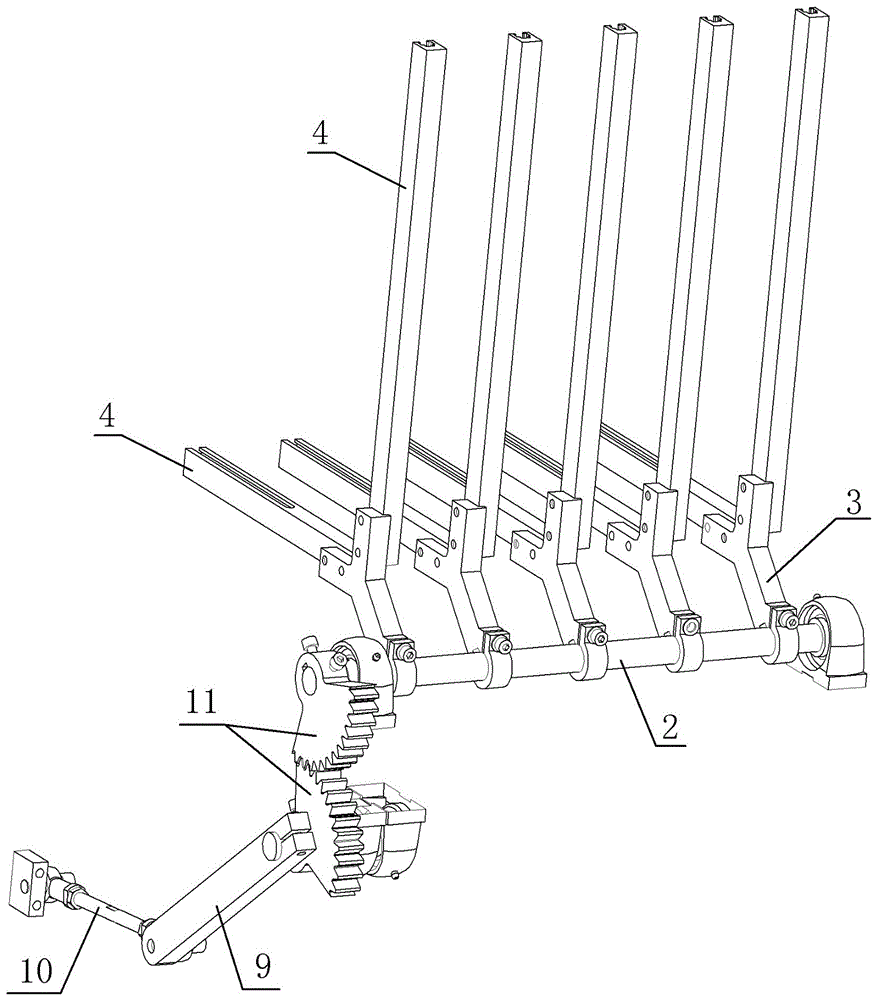

[0010] Such as Figure 1-3 shown.

[0011] A box turning device, comprising a roller conveyor belt 1 for transporting boxes, a rotating shaft 2 that rotates around its own axis, and a drive assembly that drives the rotating shaft to rotate. The rotating shaft is arranged under the drum, and the axis of the rotating shaft is aligned with the axis Vertically, there is a support rod 3 that rotates with the rotating shaft. The supporting rod is perpendicular to the shaft body of the rotating shaft and is arranged below the gap between adjacent rollers. One end of the supporting rod is fixedly installed on the rotating shaft, and the other end is equipped with two mutual The vertical overturning rod 4 can drive two overturning rods to protrude above the drum at the same time during the rotation of the pole with the rotating shaft, or drive one of the overturning rods to move to no higher than the top surface of the drum; the pole 3 and the two The included angle between the 4 turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com