a heat shrinking machine

A technology of heat shrinking machine and shrinking space, which is applied in the directions of wrapping paper shrinkage, packaging, wrapping paper, etc., can solve the problems of poor effect, poor heat shrinkage effect, and inability to realize heat shrinkage of packaging, so as to reduce the work and improve the Air flow, the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

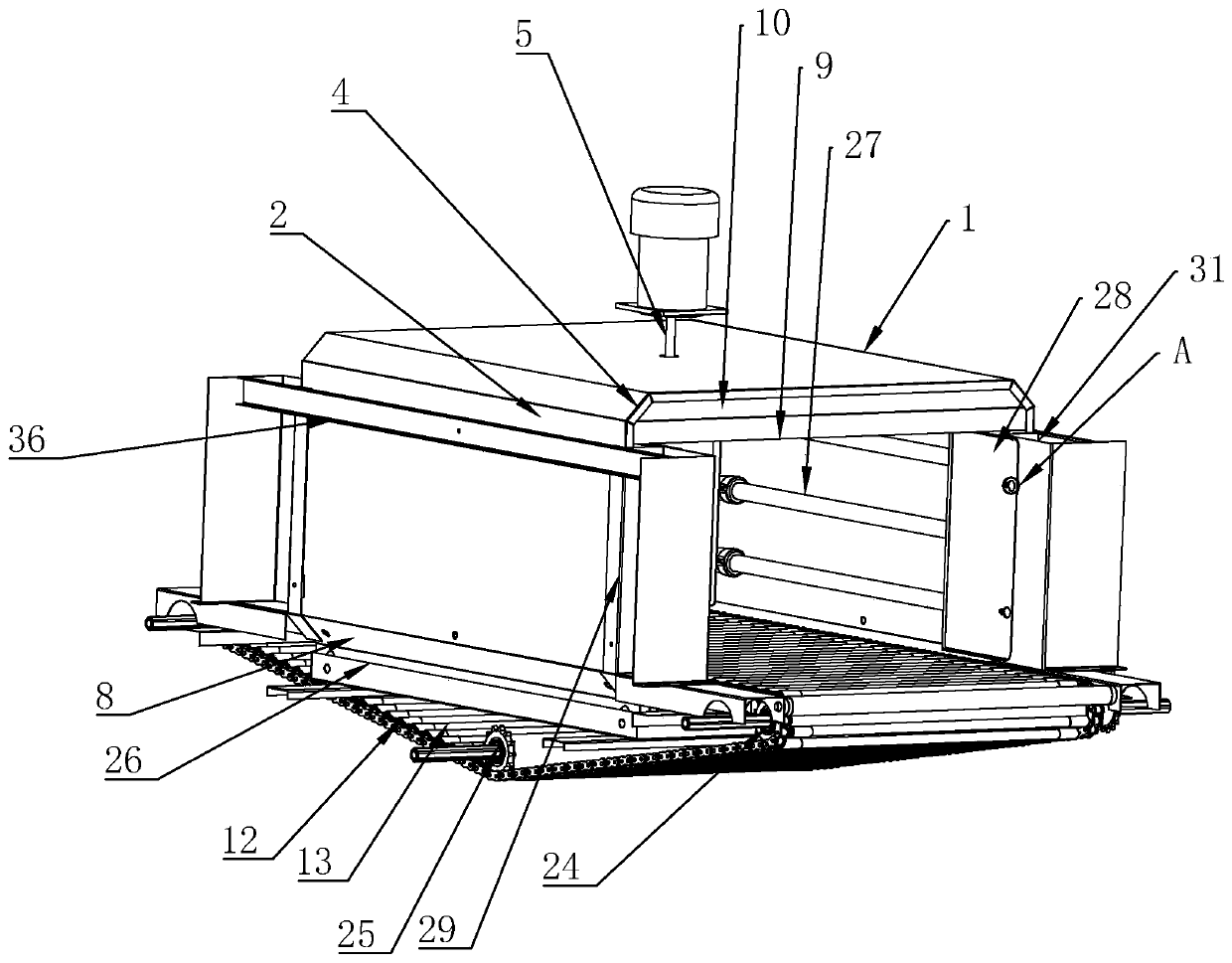

[0041] As a specific embodiment of the improvement, a second inclined plate 8 is provided on the side of the side mounting plate 2 facing away from the top plate 1, and the second inclined plate 8 is inclined toward the heat shrinkable space 3.

[0042] Through the arrangement of the second inclined plate 8, it is possible to make the air flow more smoothly under the guidance of the second inclined surface when the air flow passes under the heat shrink space 3, and further promote the uniform distribution of the hot air flow.

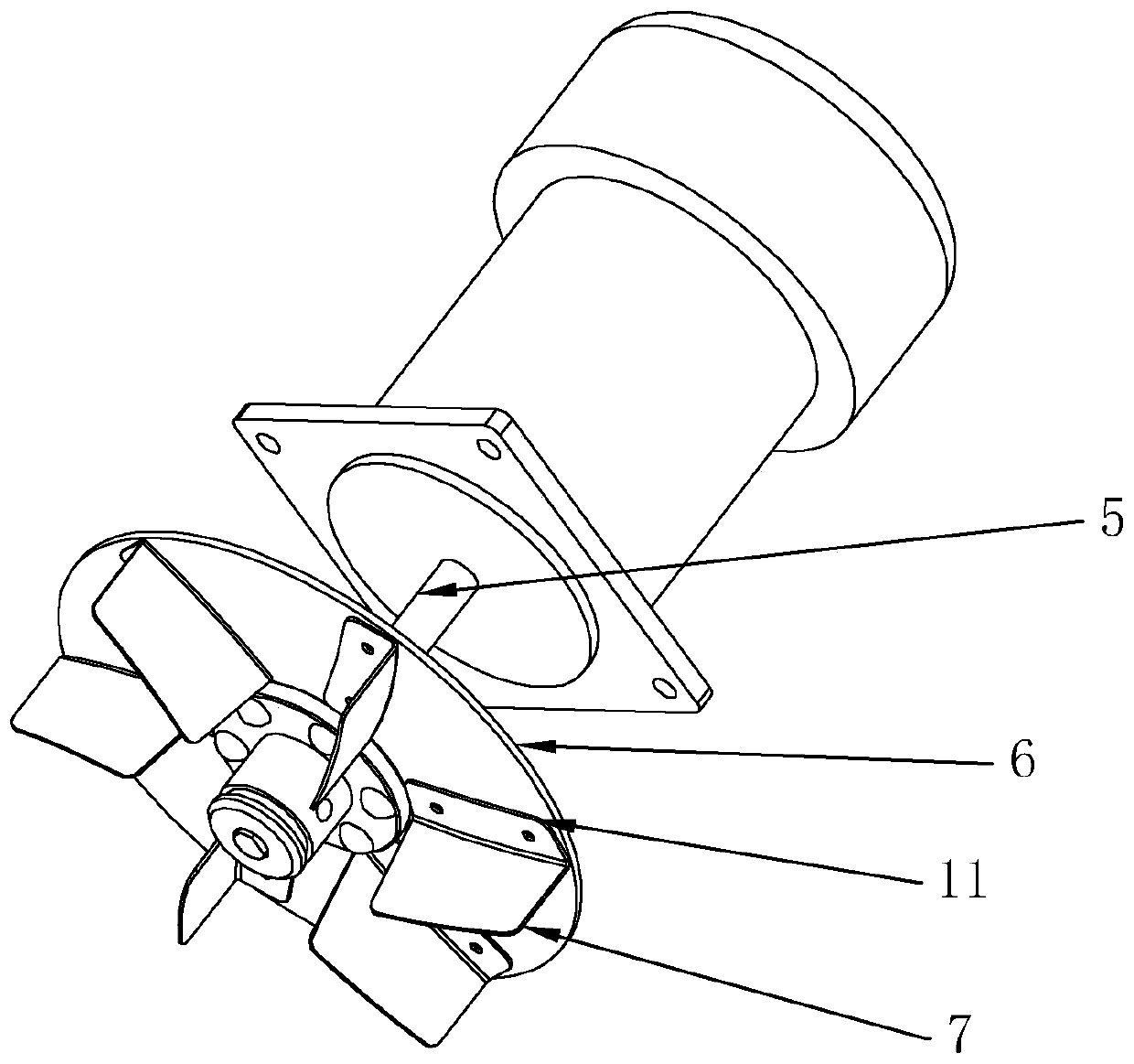

[0043] As an improved specific embodiment, the mounting plate 11 is fixed on the rotating disk 6.

[0044] Since the hot air flow will flow upward, the arrangement of the upper sealing plate 9 can block the hot air flow in the material conveying direction of the material conveying channel and avoid the loss of heat. At the same time, the arrangement of the third inclined plate 10 can play a role of diversion in the material conveying direction of the material ...

specific Embodiment approach

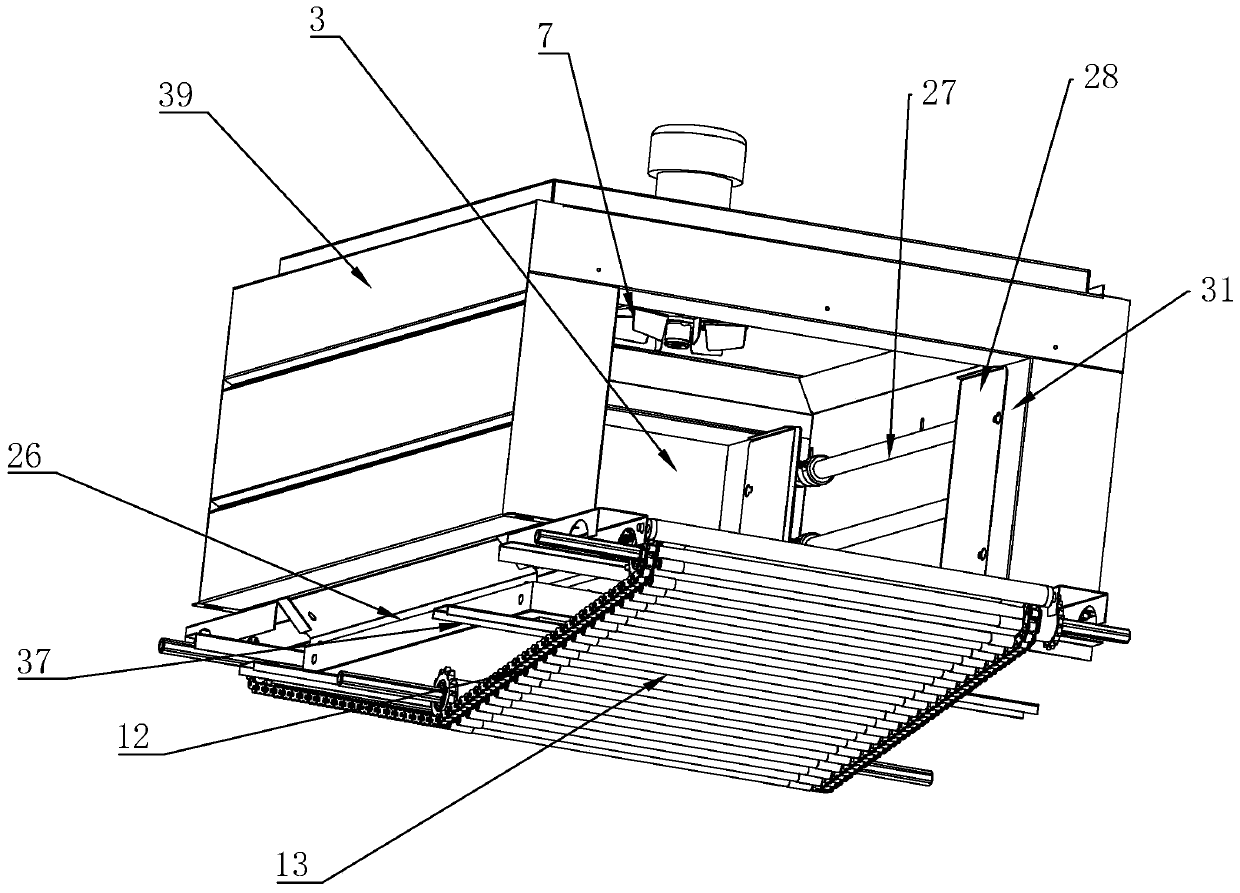

[0060] As an improved specific embodiment, a lower mounting plate 26 is provided below the side mounting plate 2. The lower mounting plate is located in the annular hollow formed by the transmission chain 12. The side mounting plate 2 and the lower mounting plate 26 A heater 27 is provided toward the heat shrink space 3, the side mounting plate 2 is provided with side baffles 28 at the entrance and exit of the transmission mechanism, and the heater 27 on the side mounting plate 2 is located at the entrance and exit of the transmission mechanism It is located between the side mounting plate 2 and the side baffle 28, leaving a gap between the side baffle 28 and the heater 27.

[0061] The lower mounting plate 26 is arranged in the annular hollow formed by the transmission chain 12, so that it can also play an additional role under the package transported on the transmission chain 12, so that the entire package can be completely heat-shrinked during the heat shrinking process . In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com