Material bag automatic scratching feeding device

A technology of feeding device and material bag, which is applied in packaging, transportation and packaging, and unsealing of objects, etc., to achieve the effects of saving raw materials, simple design structure, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, various embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

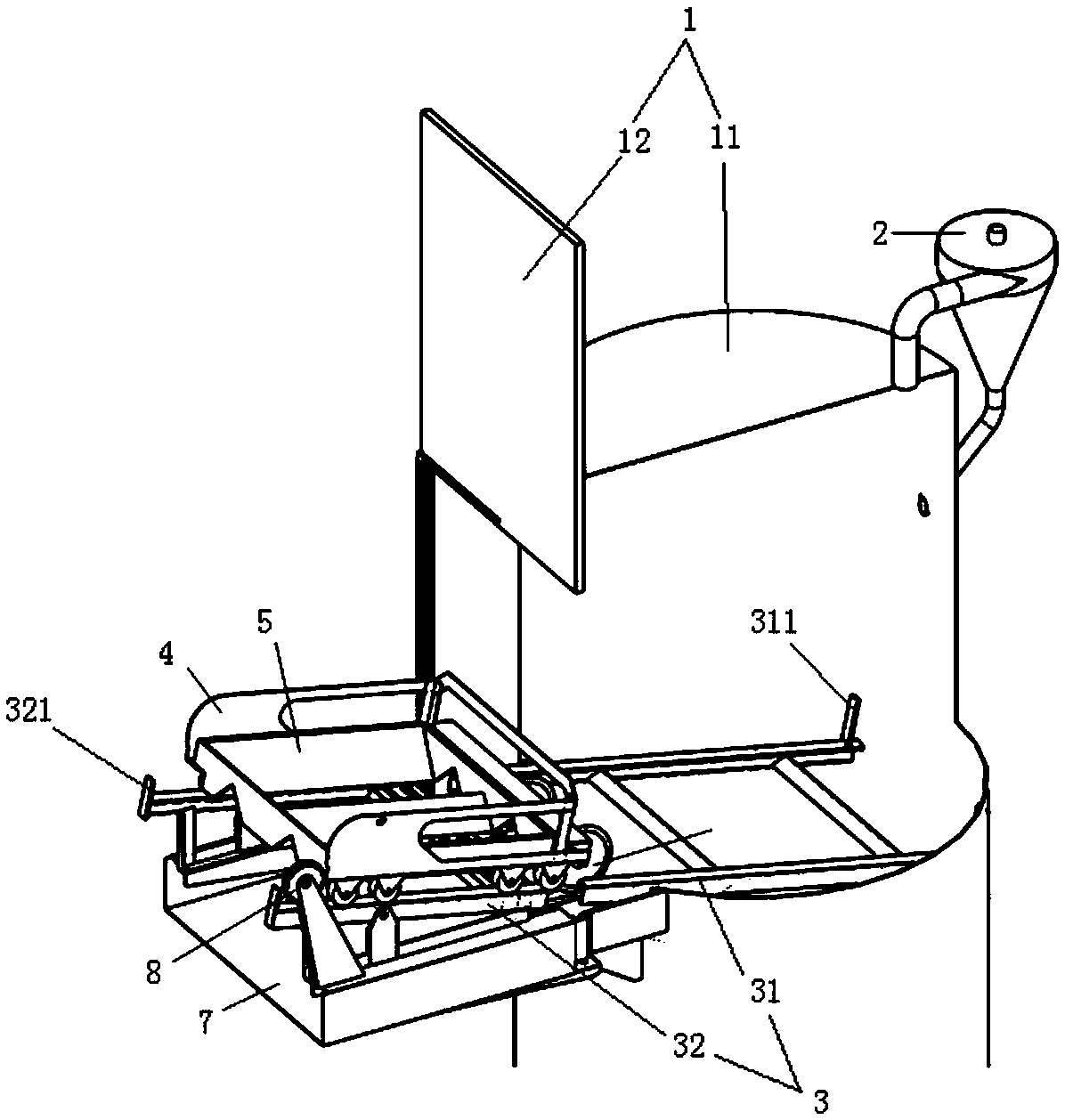

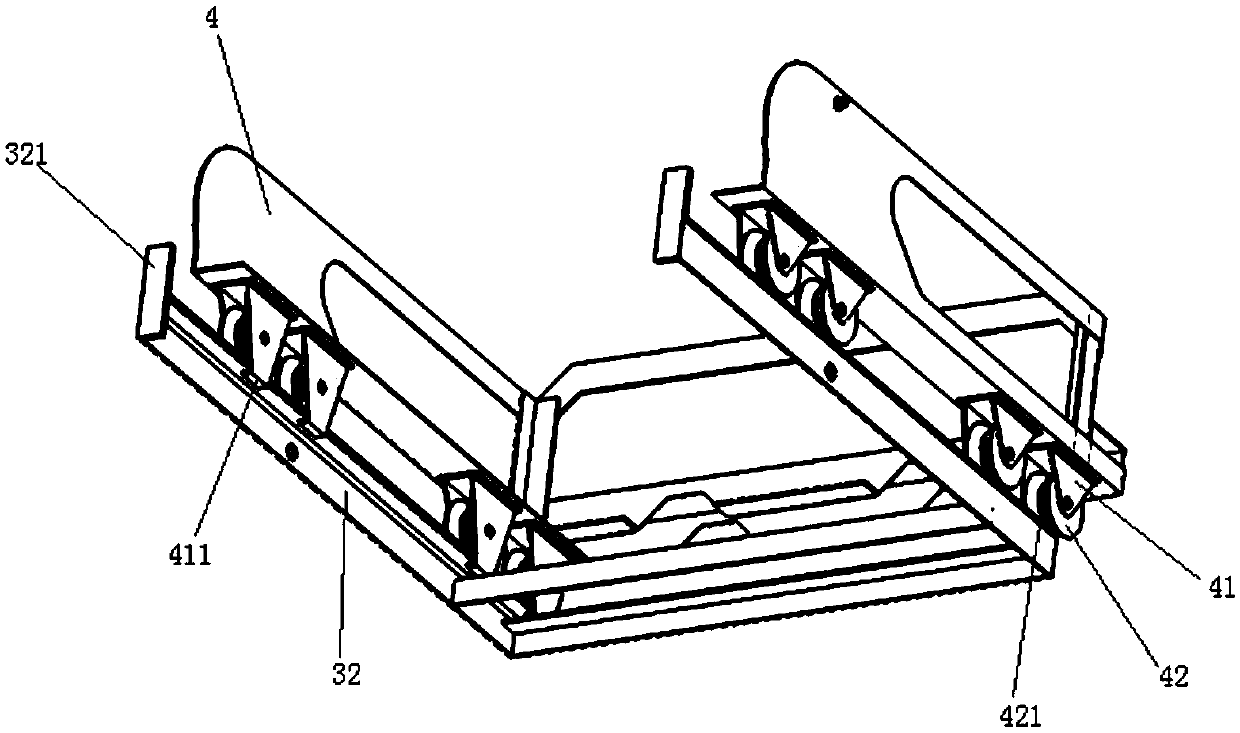

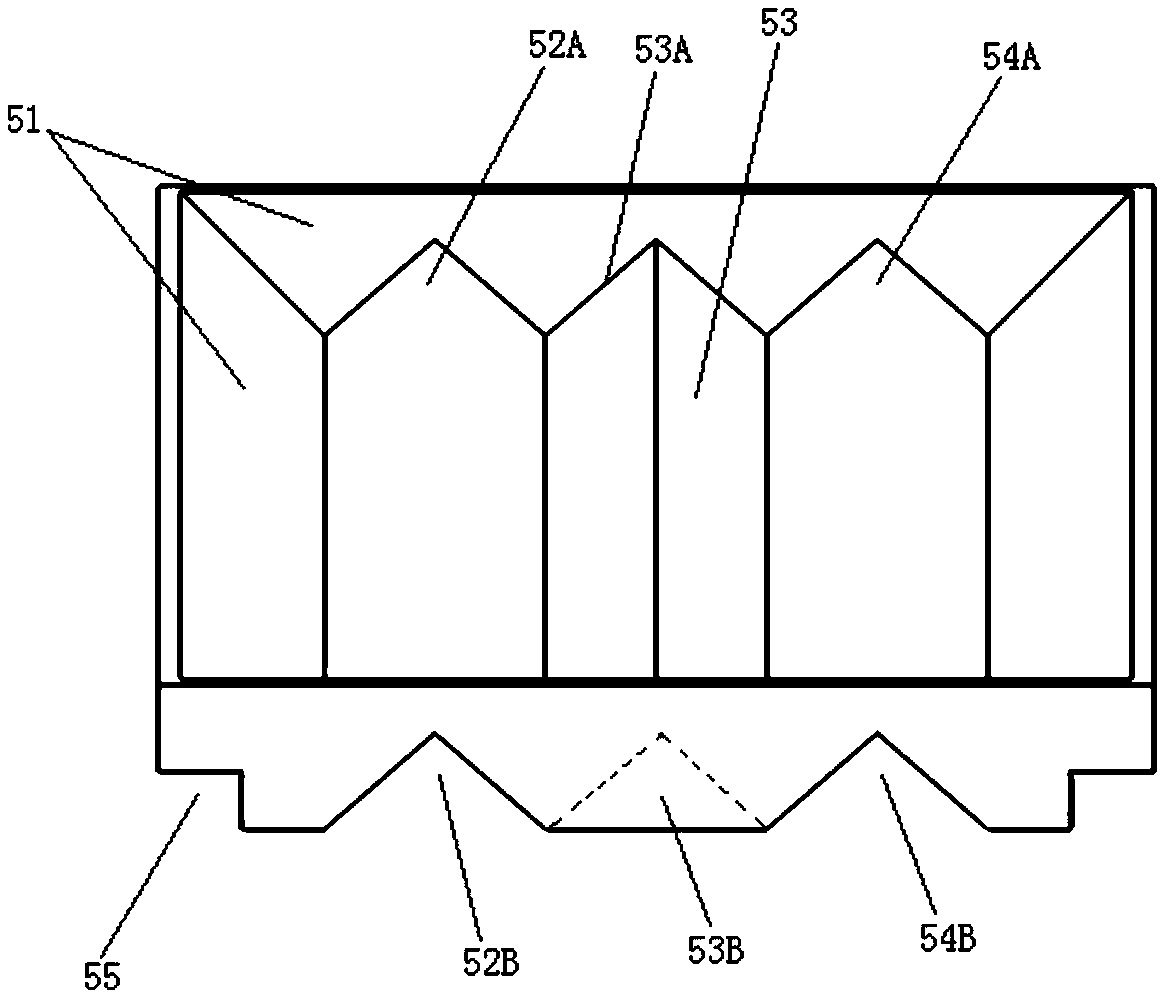

[0030] like Figure 1-3 As shown, a material bag automatic scratch feeding device includes a material tower 1, a cyclone separator 2, a guide rail 3, a transport mechanism and a cutting knife 6, the cyclone separator 2 is installed on the top of the material tower 1, and the cyclone separator 2 It is used for ventilation, so that the dust at the entrance of the material tower 1 is not easy to raise and the material is recovered into the material tower 1 by centrifugal force; the guide rail 3 extends to the inside of the material tower 1, and the transportation mechanism transports the material on the guide rail 3; it is located at the entrance of the material tower 1 A cutting knife 6 is installed on the guide rail 3 at the place, and the cutting kn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com