A pressure wheel flying coin mechanism

A roller mechanism, fly coin technology, applied in conveyors, optical testing flaws/defects, chute and other directions, can solve the problems of uneven transportation speed, change of coin output speed, slight rotation, etc., to achieve gradual friction resistance, friction resistance The effect of smooth change and reduction of rigid shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

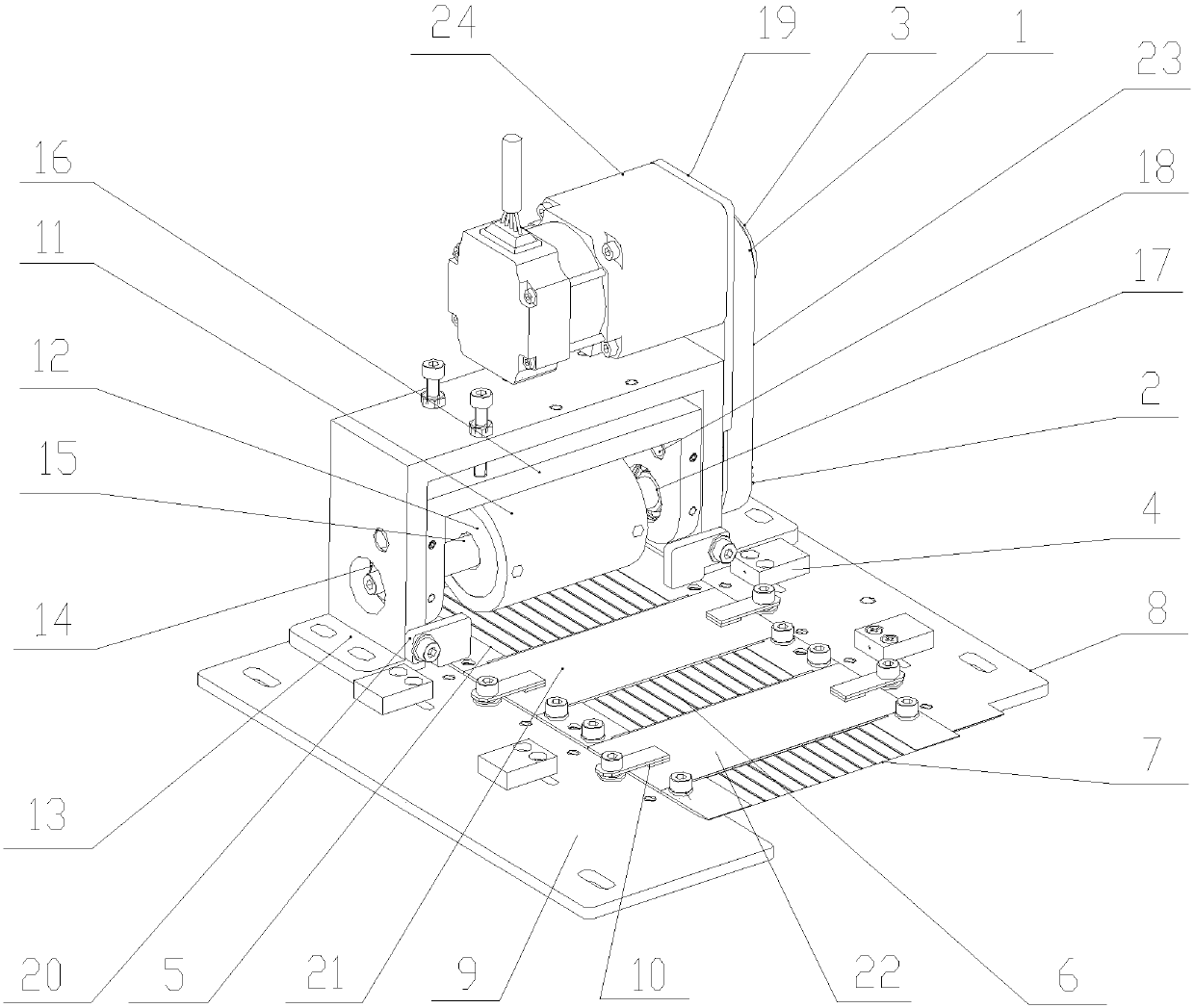

[0023] Such as figure 1 As shown, a pressure wheel flying coin mechanism includes a slideway and a roller mechanism installed at the outlet end of the conveyor belt; it also includes a first support plate 8 and a second support plate 9 arranged on both sides of the slideway; the slideway includes a spacer A ceramic slide plate and a glass slide plate are provided; the roller mechanism is arranged on the slideway, and the roller mechanism includes a roller 11 driven by a motor 24, and a certain gap is provided between the roller 11 and the slideway.

[0024] The roller mechanism of the present invention also includes an outer gantry frame 13 arranged on the first support plate 8 and the second support plate 9, the outer gantry frame 13 is connected with an inner gantry frame 16, and the inner gantry frame 16 is internally installed Roller 11 is arranged, and described roller 11 rotates on inner gantry frame 16 through rotating shaft 15, and described rotating shaft 15 passes th...

Embodiment 2

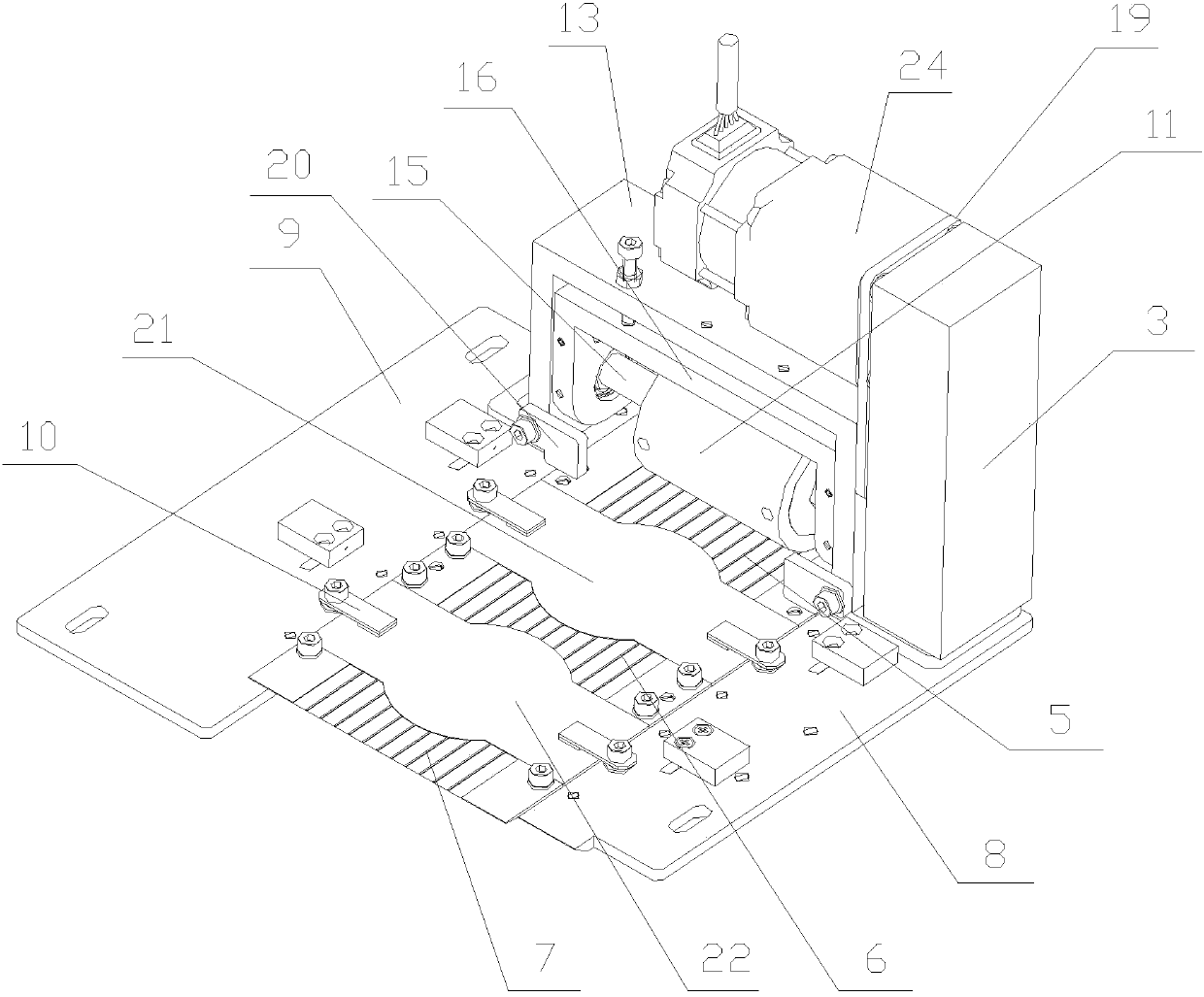

[0029] Such as figure 2 As shown, a pressure wheel flying coin mechanism includes a slideway and a roller mechanism installed at the outlet end of the conveyor belt; it also includes a first support plate 8 and a second support plate 9 arranged on both sides of the slideway; the slideway includes a spacer A ceramic slide plate and a glass slide plate are provided; the roller mechanism is arranged on the slideway, and the roller mechanism includes a roller 11 driven by a motor 24, and a certain gap is provided between the roller 11 and the slideway.

[0030] Both sides of the glass sliding plate of the present invention are symmetrically provided with arc-shaped transition blocks, and both sides of the ceramic sliding plate are provided with arc-shaped notches matching the arc-shaped transition blocks.

[0031] In order to effectively control and reduce the change of the sliding speed and sliding direction of the coin during the flying coin conveying, when designing the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com