Lifting machine

A hoist and frame technology, which is applied in the field of hoist and color sorter for color sorter feeding, can solve the problems of low work efficiency, blockage of the discharge port, and less material at one time, and achieve the process of feeding and discharging. The effect of smoothness, reduced footprint, and reduced friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution and structure of the present invention will be described below in conjunction with the accompanying drawings, so as to facilitate the understanding of those skilled in the art.

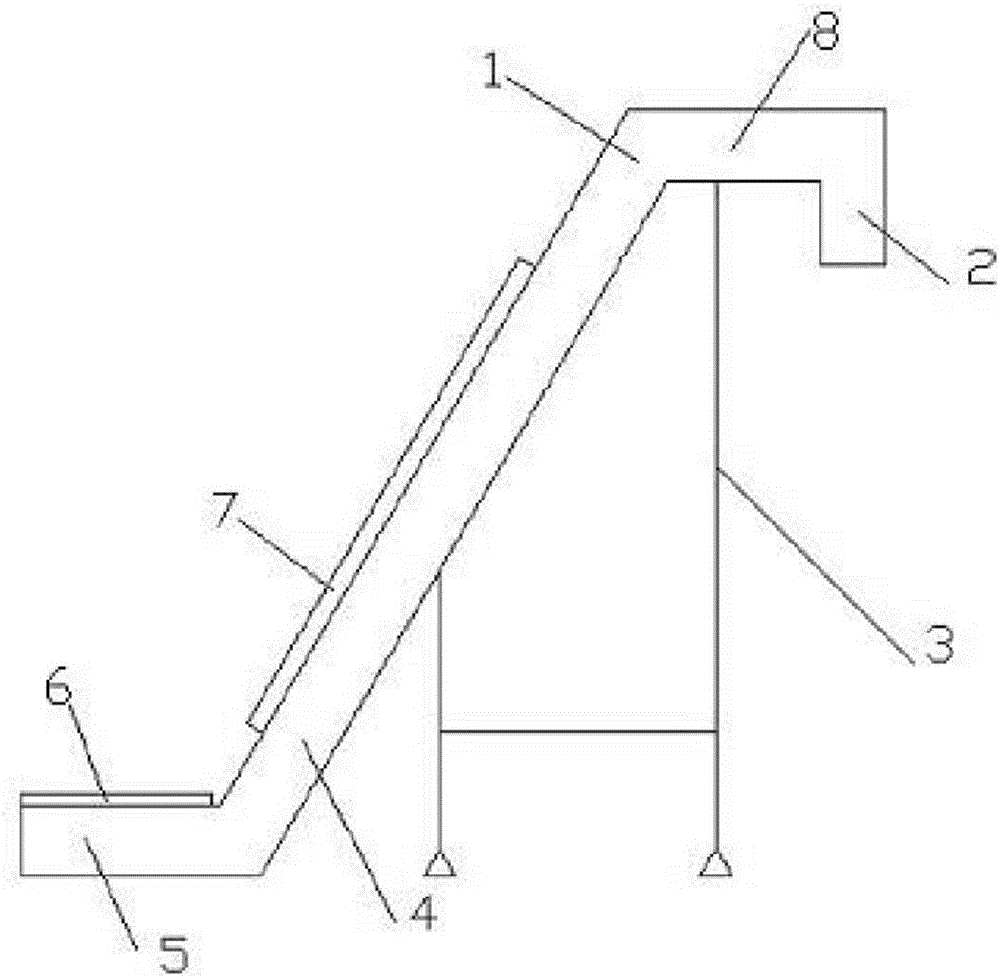

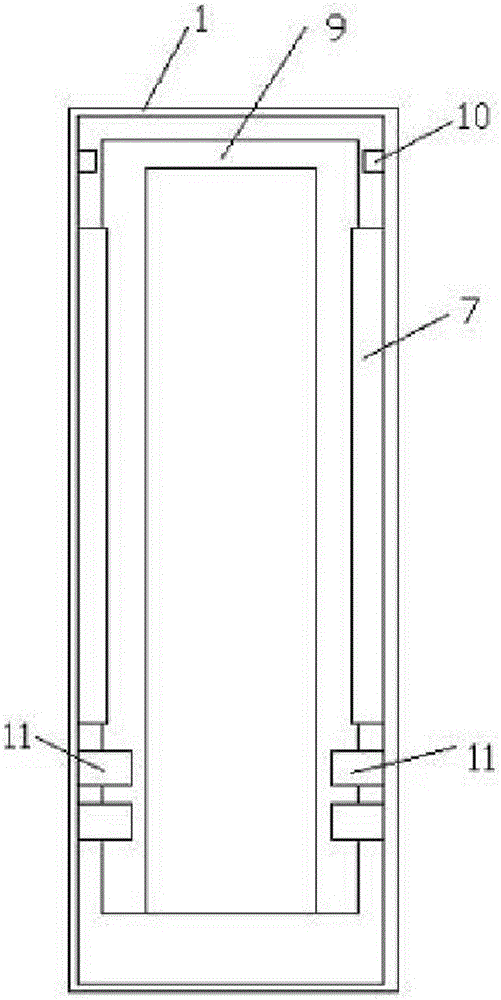

[0019] like figure 1 and figure 2 Shown, a kind of lifting machine comprises frame, and described frame interior is provided with conveyer belt, and frame includes feeding part and discharging part, is provided with lifting part between feeding part and discharging part, feeding part and The discharge part is parallel to the ground, and the lifting part is at an angle of 60 degrees to the ground. The conveyor belt passes through the feeding part, lifting part and discharging part. The left and right edges of the conveyor belt near the feeding part are equipped with pressure wheels. There are more than one pressure wheels on the left and right edges of the belt, and the pressure wheels can rotate around the axis of the pressure wheels themselves. The left and right edges...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com