Full-life-cycle management method of aluminum electrolysis anode and aluminum electrolysis anode

A full life cycle, aluminum electrolytic anode technology, applied in the field of aluminum electrolysis, can solve the problem of anode consumption rate suppliers and batches can not be correlated and traced, can not accurately collect aluminum guide rod repair and replacement spare parts and material information, anode location , status tracking difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

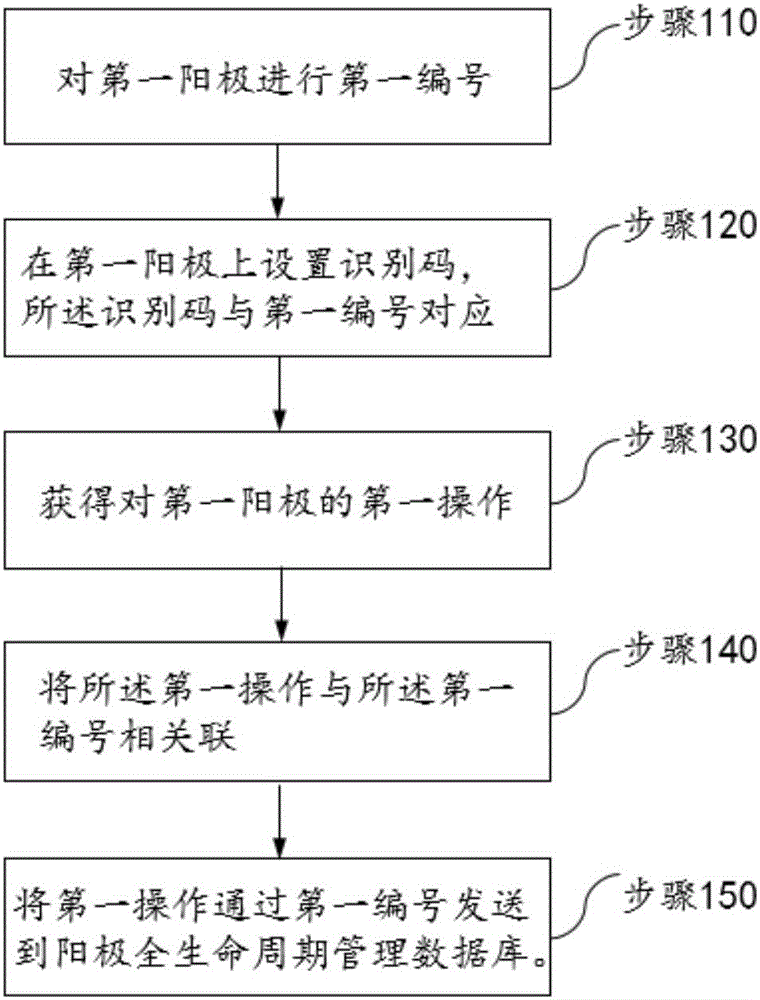

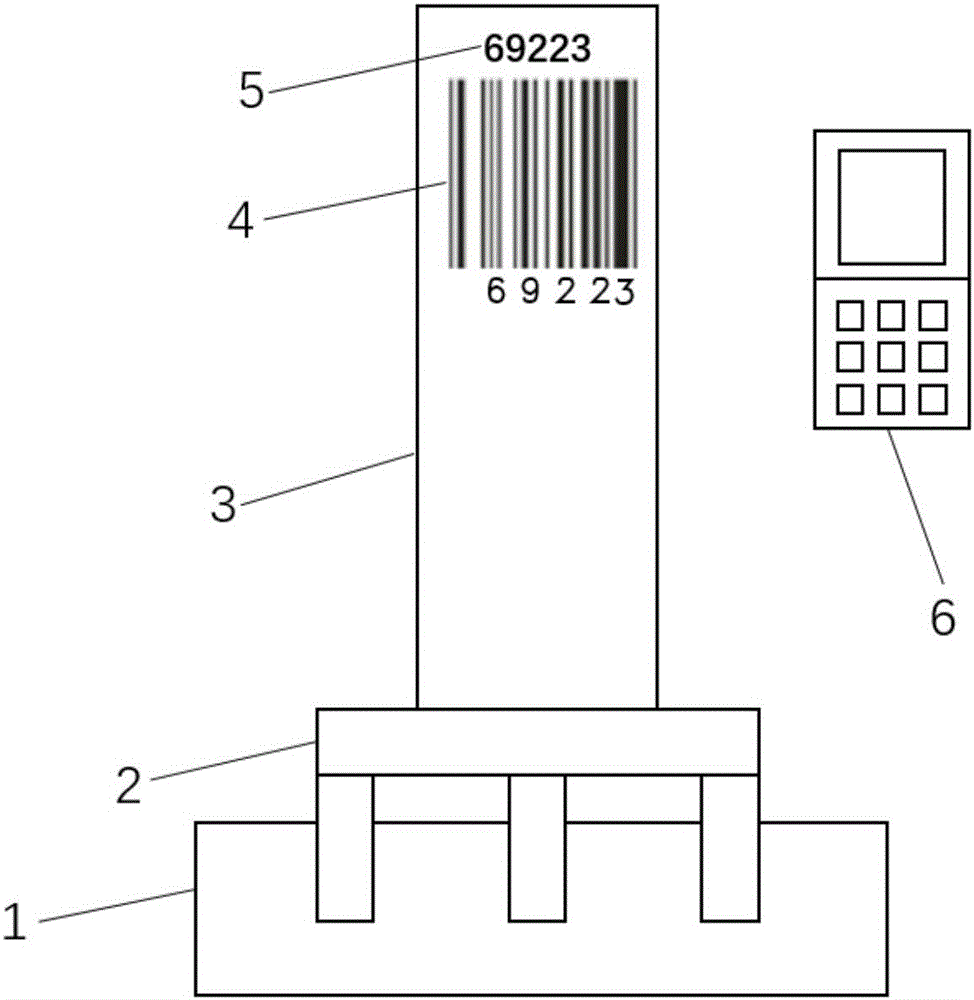

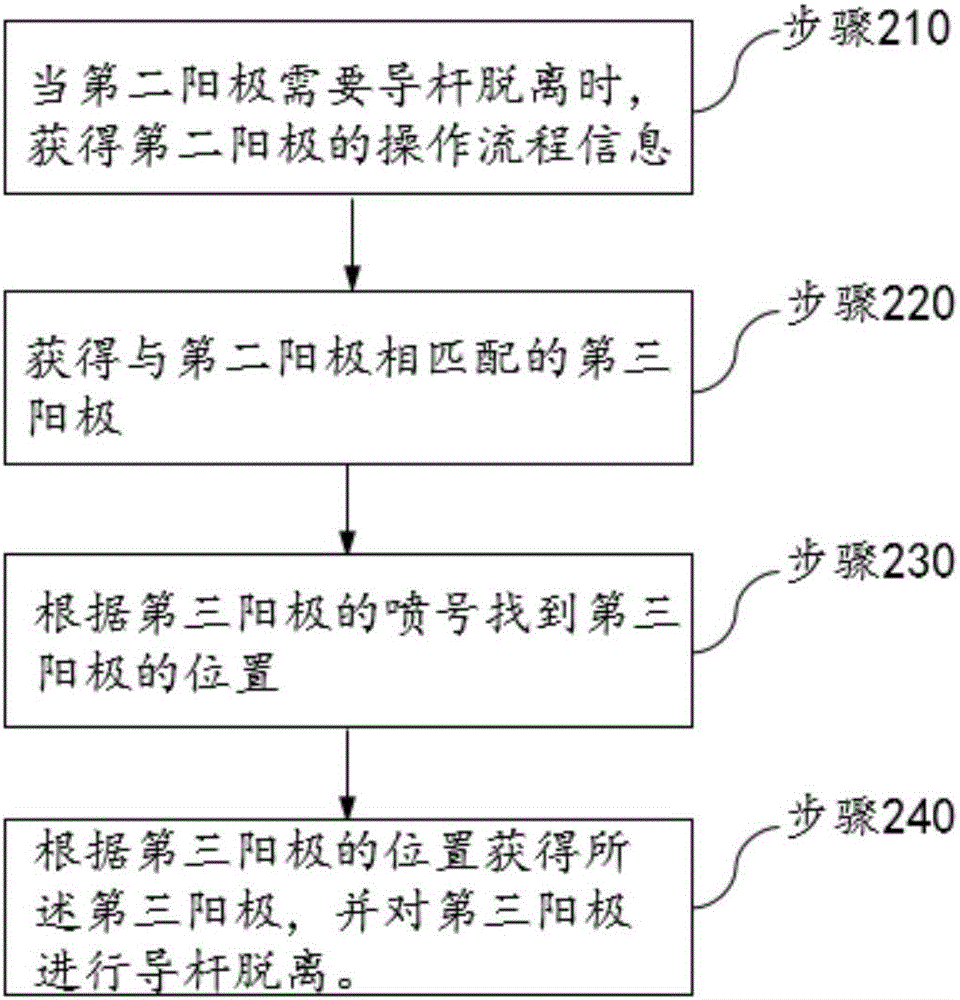

[0032] Such as figure 1 As shown, the embodiment of the present application provides a full life cycle management method for aluminum electrolytic anodes, wherein the method includes:

[0033] Step 110: Carry out a first number for the first anode;

[0034] Specifically, in order to achieve effective management of the aluminum electrolytic anodes, each anode needs to be identified, and after identification, the use, inspection, management, etc. of each anode are stored in the computer, and according to the computer's Information entry, information change management.

[0035] For this application, the first numbering of the first anode is the process of establishing the correspondence between each anode and the management information in the computer, that is to say, each anode will be numbered in the management information of the computer, so that the actual Each anode in the computer has its own ID, ie number, in the management information of the computer.

[0036] For exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com