Intelligent stepping tightening and loosing device for flat knitting machine

A flat knitting machine and intelligent technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of small adjustment range, limitation, and inability to automatically correct errors, etc., to achieve the effect of improving accuracy and widening adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

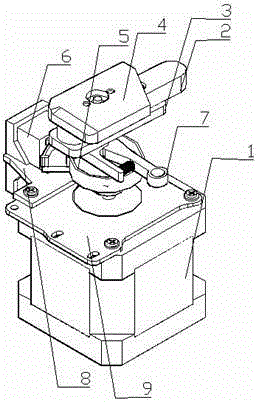

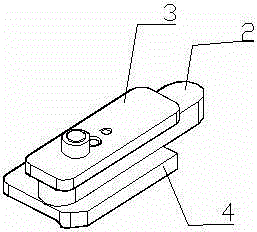

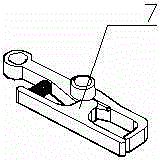

[0013] Please refer to the accompanying drawings, the present invention is an intelligent flat knitting stitch tightening device, which includes a stitch motor 1, a slider 2, a sliding bracket 3, a baffle plate 4, a snail-shaped cam 5, an inductor 6, a sliding elastic bracket 7, Fixed support 8 and fixed bracket 9 are formed. Wherein, the stitch motor 1 is fixed on the intelligent flat knitting machine by a fixed bracket 9; the stitch motor 1 is connected with the snail-shaped cam 5, and the stitch motor 1 drives the snail-shaped cam 5 to rotate; the sliding elastic bracket 7 and the snail Adopt sliding connection between shaped cam 5, when snail shaped cam 5 rotates, can drive the pulley motion of sliding elastic support 7 in the groove, thereby drive whole sliding elastic support 7 motions.

[0014] Described sliding bracket 3 and sliding elastic bracket 7 also adopt sliding connection, and the pulley on the sliding bracket 3 is fitted with the groove of sliding elastic brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com