Combined type prefabricated house and construction method thereof

A prefabricated house, combined technology, applied in the direction of construction, building structure, etc., can solve the problems of unrecoverable foundation, inconvenient land use, waste of resources, etc., to ensure the effect of wind resistance, easy partition, and resource saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

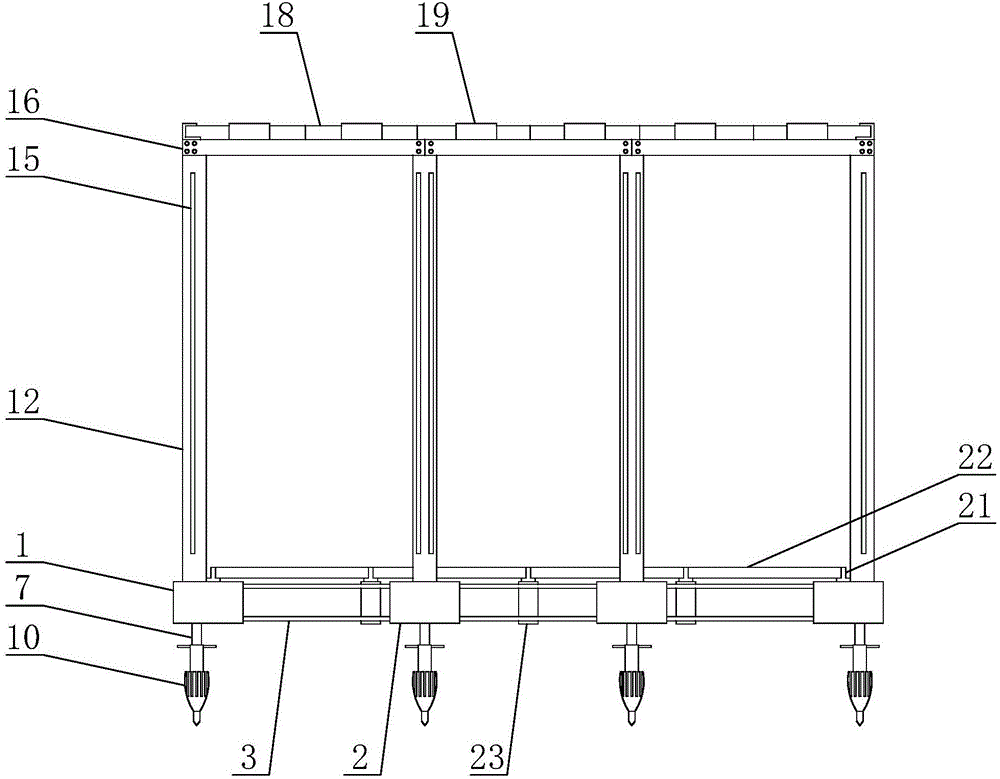

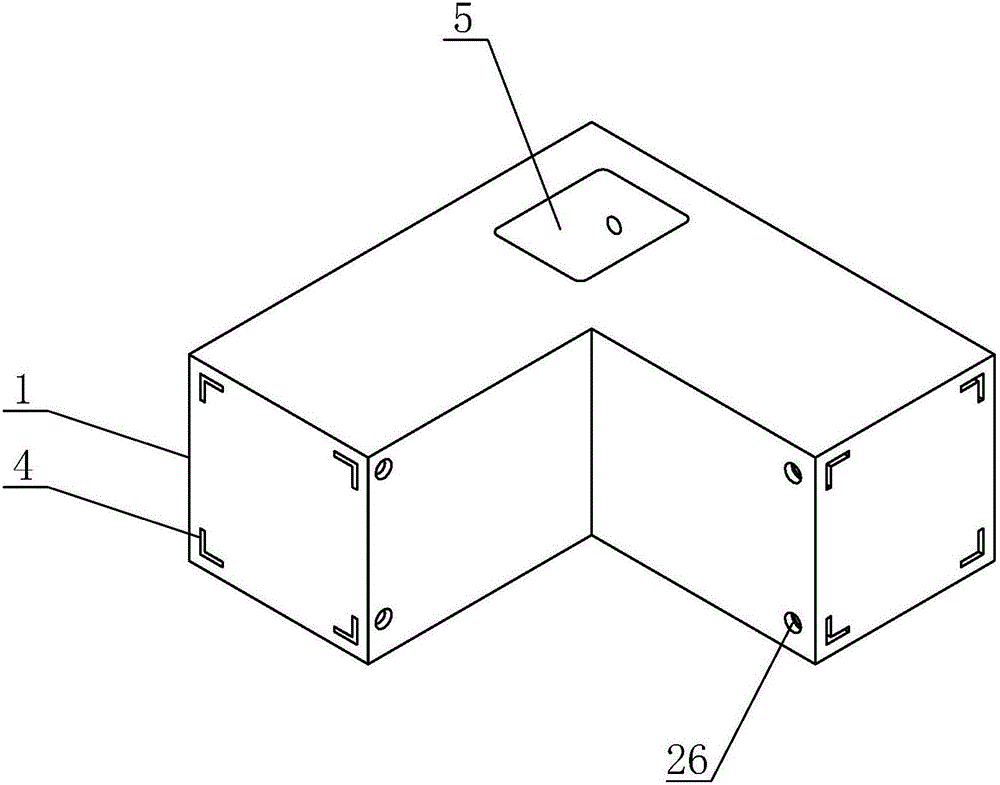

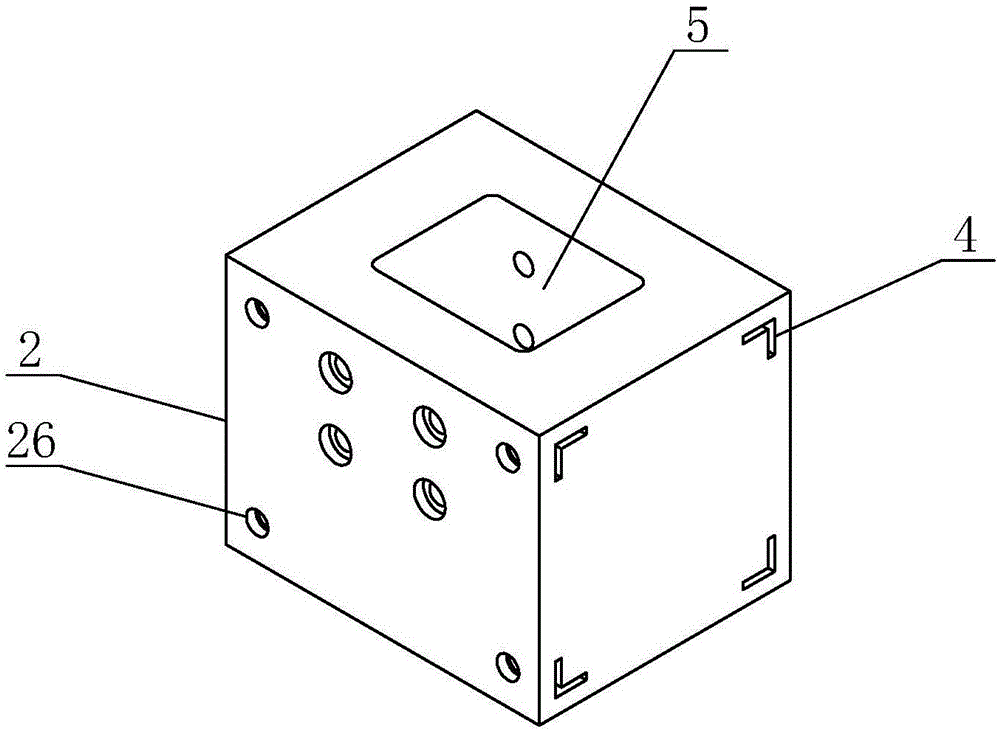

[0063] Embodiment: The present invention is a combined prefabricated house, including a foundation frame, and the outside of the foundation frame is provided with a baffle plate 30, which can close the outside of the foundation frame and facilitate the filling of gravel into the foundation frame , sandy soil, can ensure the windproof performance of the prefabricated house. The corner of the foundation frame is provided with an L-shaped corner base 1, and the partition point of the foundation frame is provided with a T-shaped corner base 24. Between the adjacent L-shaped corner bases 1 and adjacent to the T Support bases 2 are arranged between the corner bases 24, and the L-shaped corner base 1, the support base 2, and the T-shaped corner base 24 are all prefabricated by reinforced concrete. The L-shaped corner base 1, support base 2, and T-shaped corner base 24 are connected by angle steel 3 to form a Japanese-shaped foundation frame. Each end of the L-shaped corner base 1 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com