Coiled tubing clamping device and injection head adopting the clamping device

A technology of tubing injection head and clamping device, which is applied in the direction of drill pipe, casing, earthwork drilling, etc., and can solve the problem of easy wear or damage of the clamping surface of the clamping block, damage or deformation of the coiled tubing surface, and easy stress concentration and other problems to achieve the effect of reducing work costs, saving maintenance time, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention will be described in detail below in conjunction with accompanying drawing:

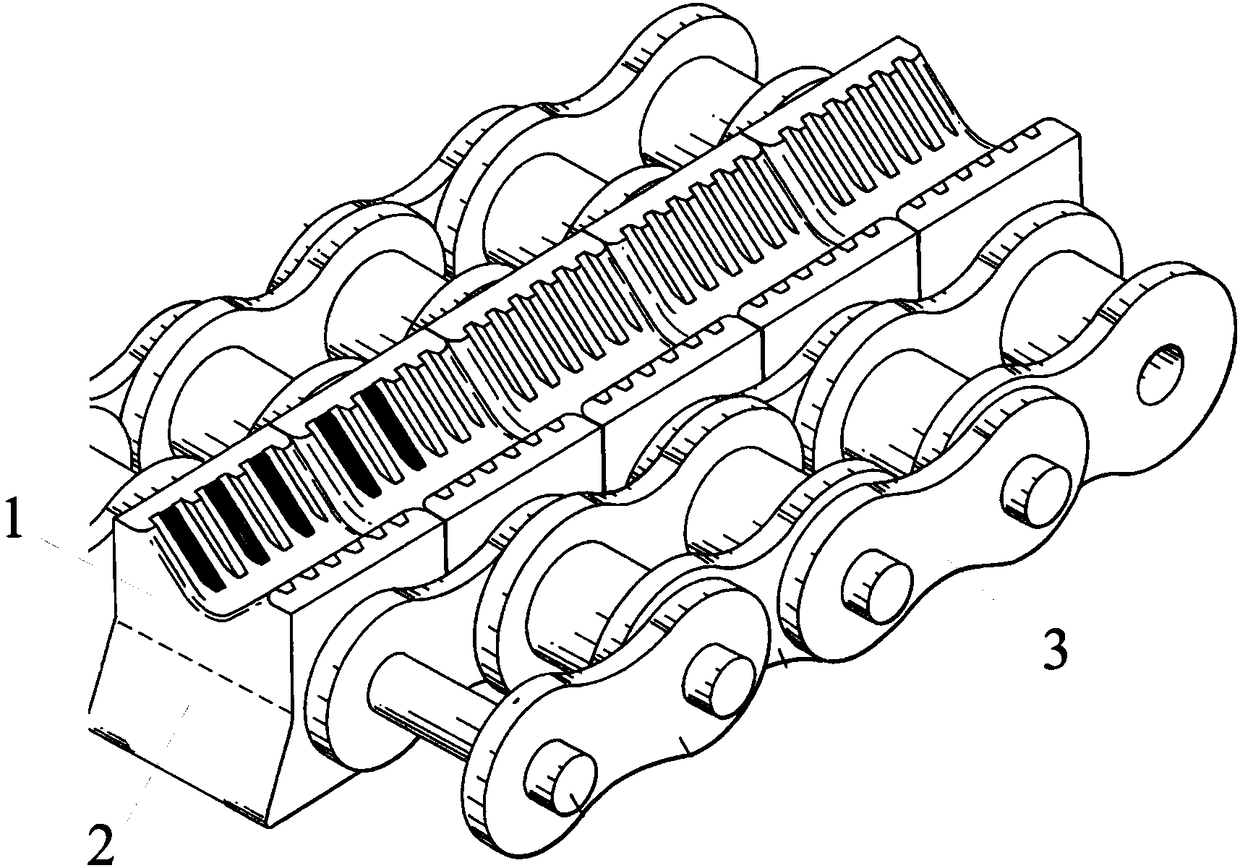

[0024] Such as figure 1 As shown, an injection head clamping device includes a clamping block 1, a clamping seat 2 and a transmission chain 3, wherein the clamping block 1 is movably connected to the clamping seat 2, and the clamping seat 2 is fixedly connected to the transmission chain 3 , thereby forming the entire injection head clamping device;

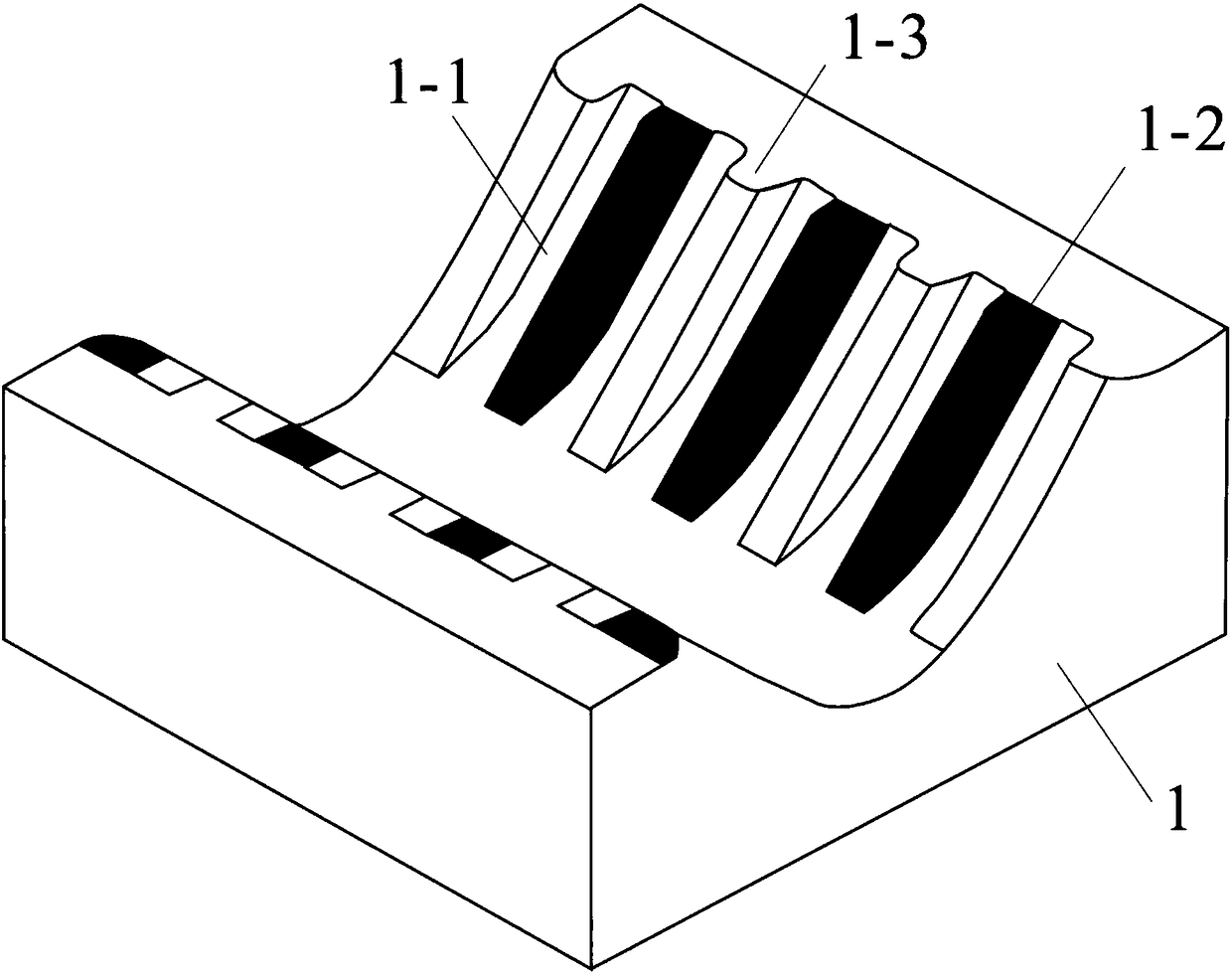

[0025] Such as figure 2 As shown, the inner surface of the clamping block 1 is a trapezoidal clamping opening, the bottom of the clamping opening is arc-shaped, and there are clamping ribs and grooves 1-1 alternately distributed on both sides of the clamping opening. , wherein the clamping ribs include plastic clamping ribs 1-2 and hard clamping ribs 1-3, the plastic clamping ribs 1-2 and the hard clamping ribs 1-3 are alternately arranged;

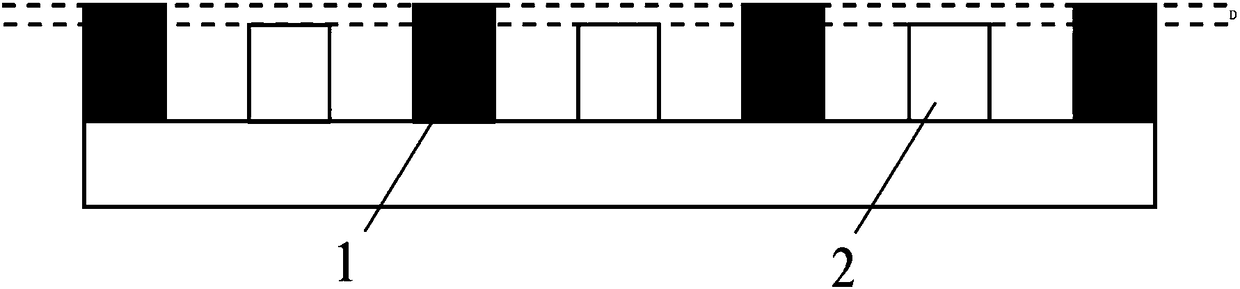

[0026] Such as image 3 As shown, the height differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com