Screw

A screw and screw body technology, applied in the direction of screws, threaded fasteners, connecting components, etc., can solve the problems of easy loss of screws and waste of raw materials, and achieve the effect of saving raw materials and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

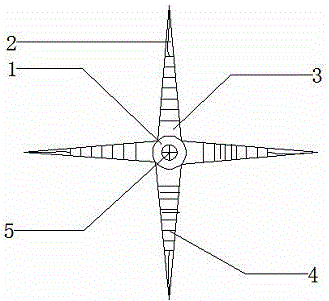

[0014] Such as figure 1 Shown, a kind of screw comprises screw body 5, and described screw body 5 is cylindrical and its outer surface is provided with serrated thread, and the head surface of described screw body 5 is provided with cross-shaped groove; Said screw body There is an annular connector 1 on the edge of the head of 5, and four conical screws are welded on the connector 1. The surface of each screw consists of three parts, and the smooth surface 3 starts from the head near the screw body 5. , Thread surface 4 and blade surface 2. The surface of the screw body 5 is coated with a polymer material. The included angle of the four conical screws is 90 degrees.

[0015] An embodiment of the present invention has been described in detail above, but the content described is only a preferred embodiment of the present invention, and cannot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com