Four-way joint

A technology of four-way joints and main pipes, which is applied in the direction of pipes/pipe joints/fittings, branch pipelines, pipes, etc., to achieve the effects of improving connection sealing, improving stability, and avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

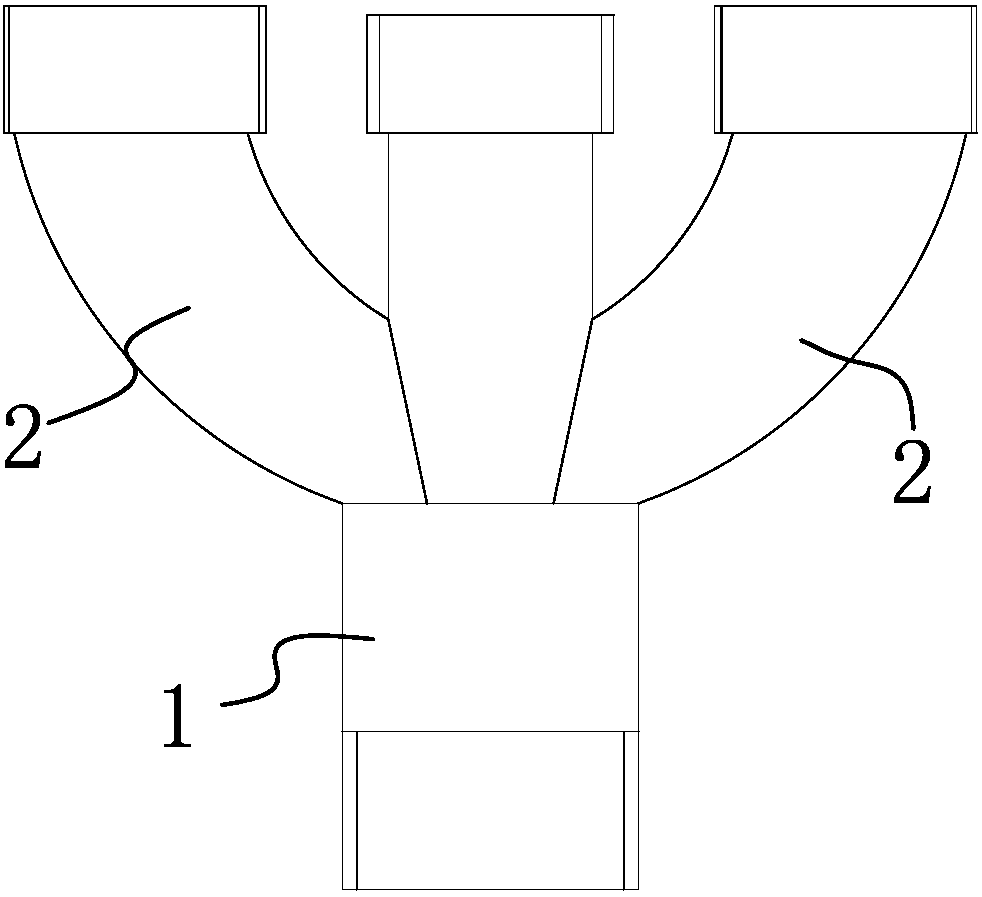

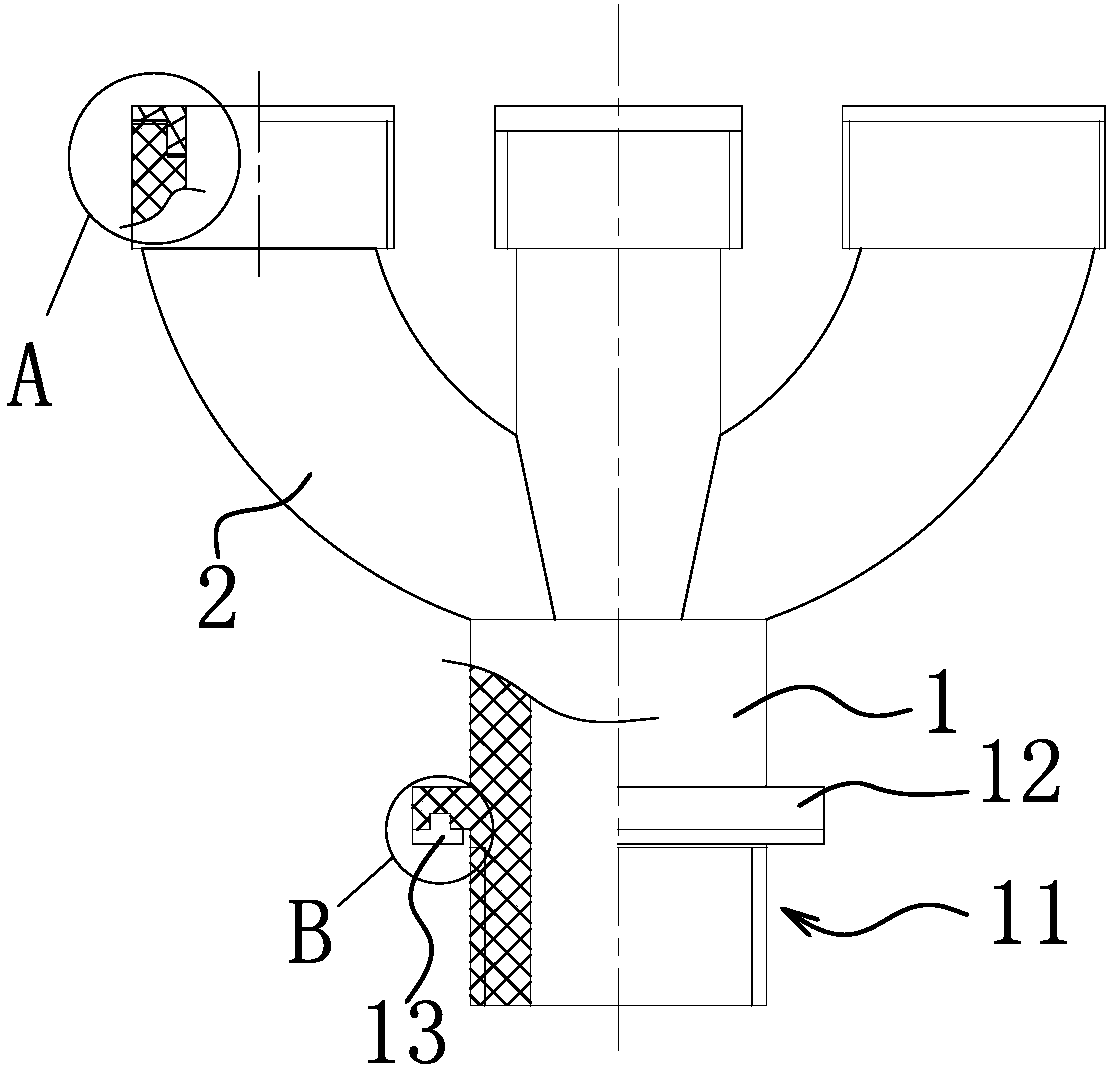

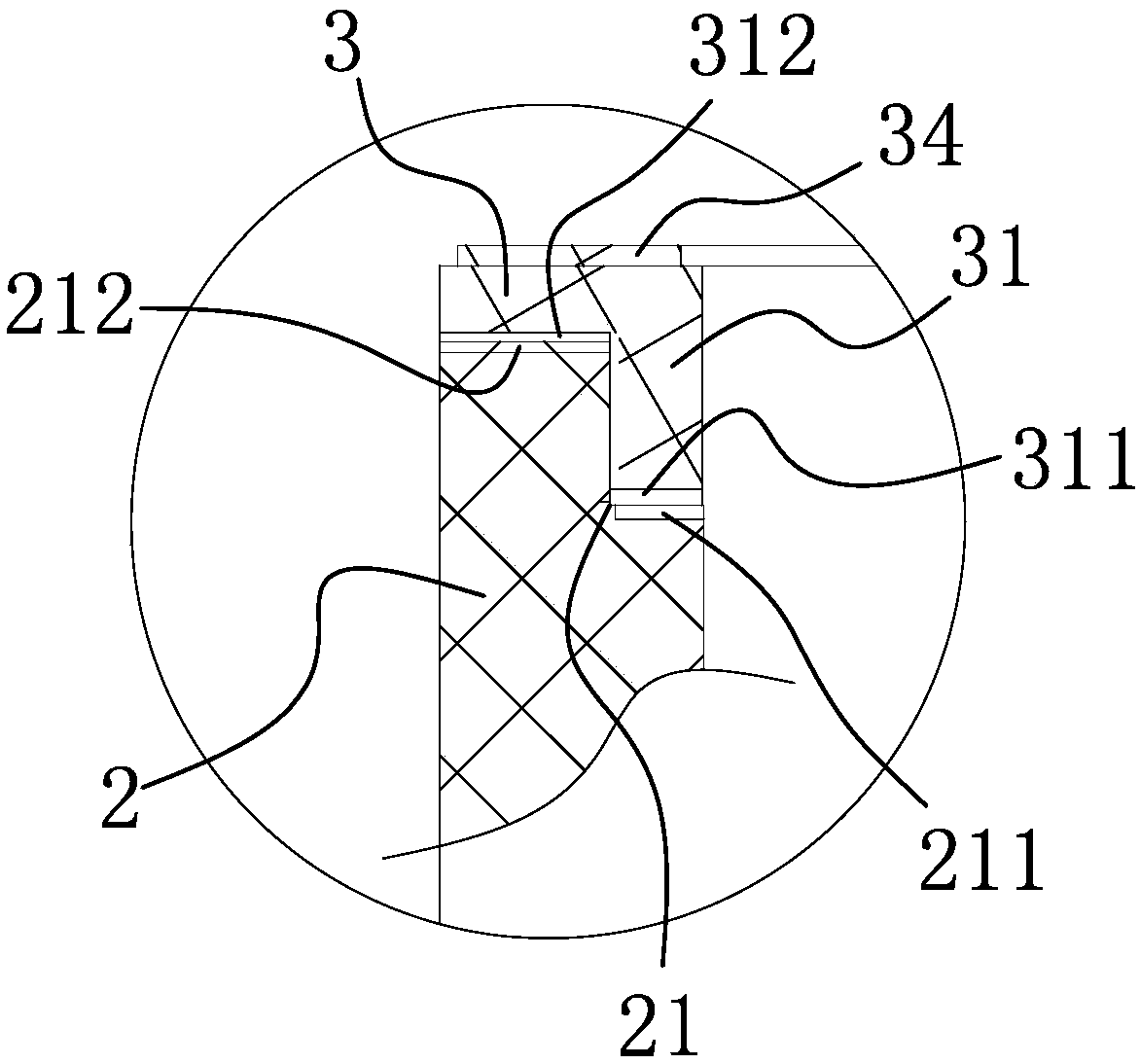

[0024] like Figure 1-4 As shown, the four-way joint includes a main pipe 1, and a first sealing connection mechanism 11 is provided at one end of the main pipe 1. Specifically, the first sealing connection mechanism 11 includes an external thread arranged on the outer wall of the main pipe 1 away from the sub-pipe 2, The external thread is connected with the internal thread of the connecting screw cap, and the outer wall of the main pipe 1 is also provided with an annular blocking portion 12 at the end of the external thread, and the side of the annular blocking portion 12 close to the external thread is provided with an annular gasket 13 .

[0025] The annular sealing gasket 13 can improve the sealing performance of the contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com