Pressure-resistant explosion-proof transfer lines for oil handling

A technology for conveying pipelines and oil treatment, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as insufficient compressive strength, avoid burst damage, ensure smooth transportation, and stick low degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

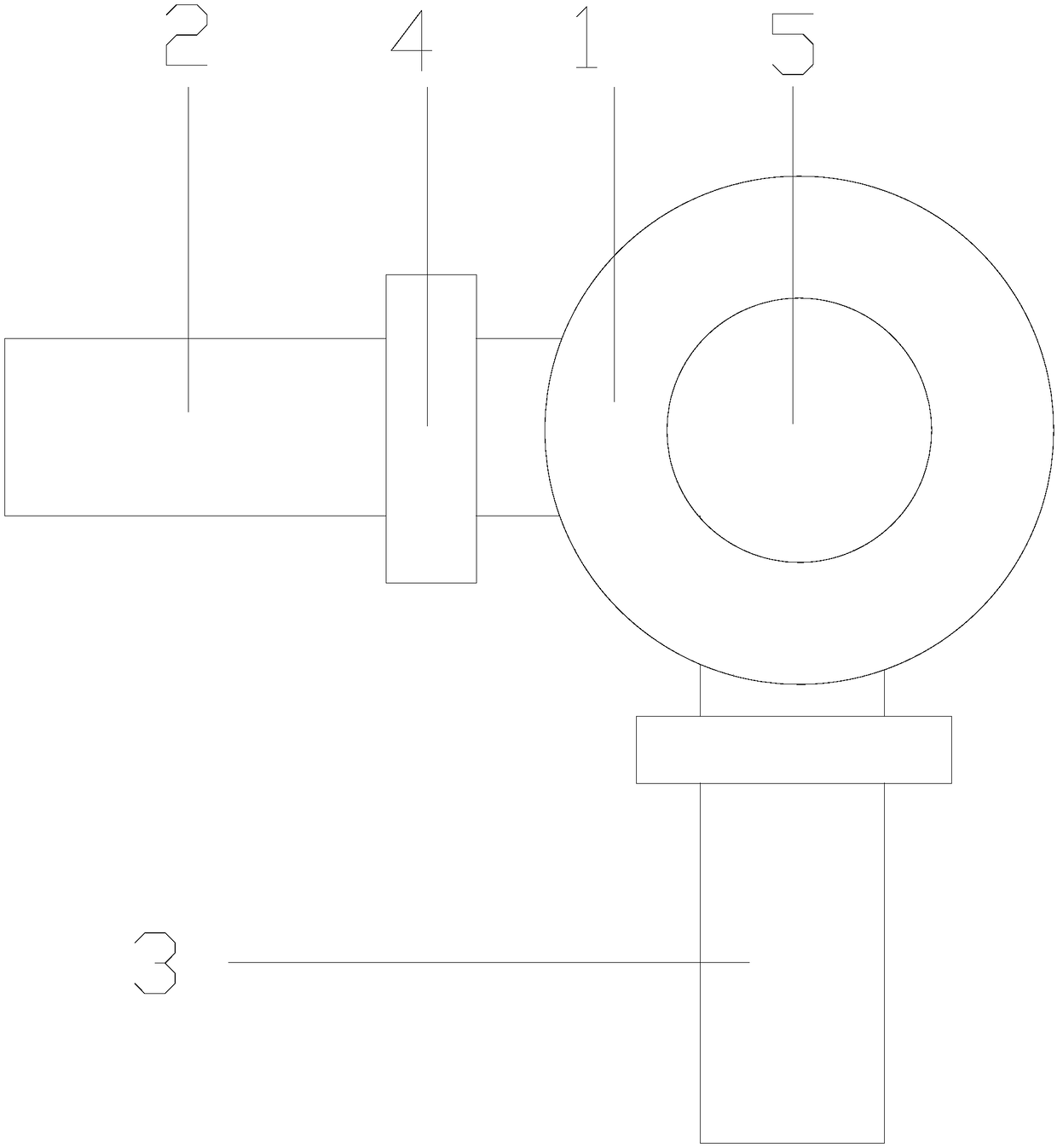

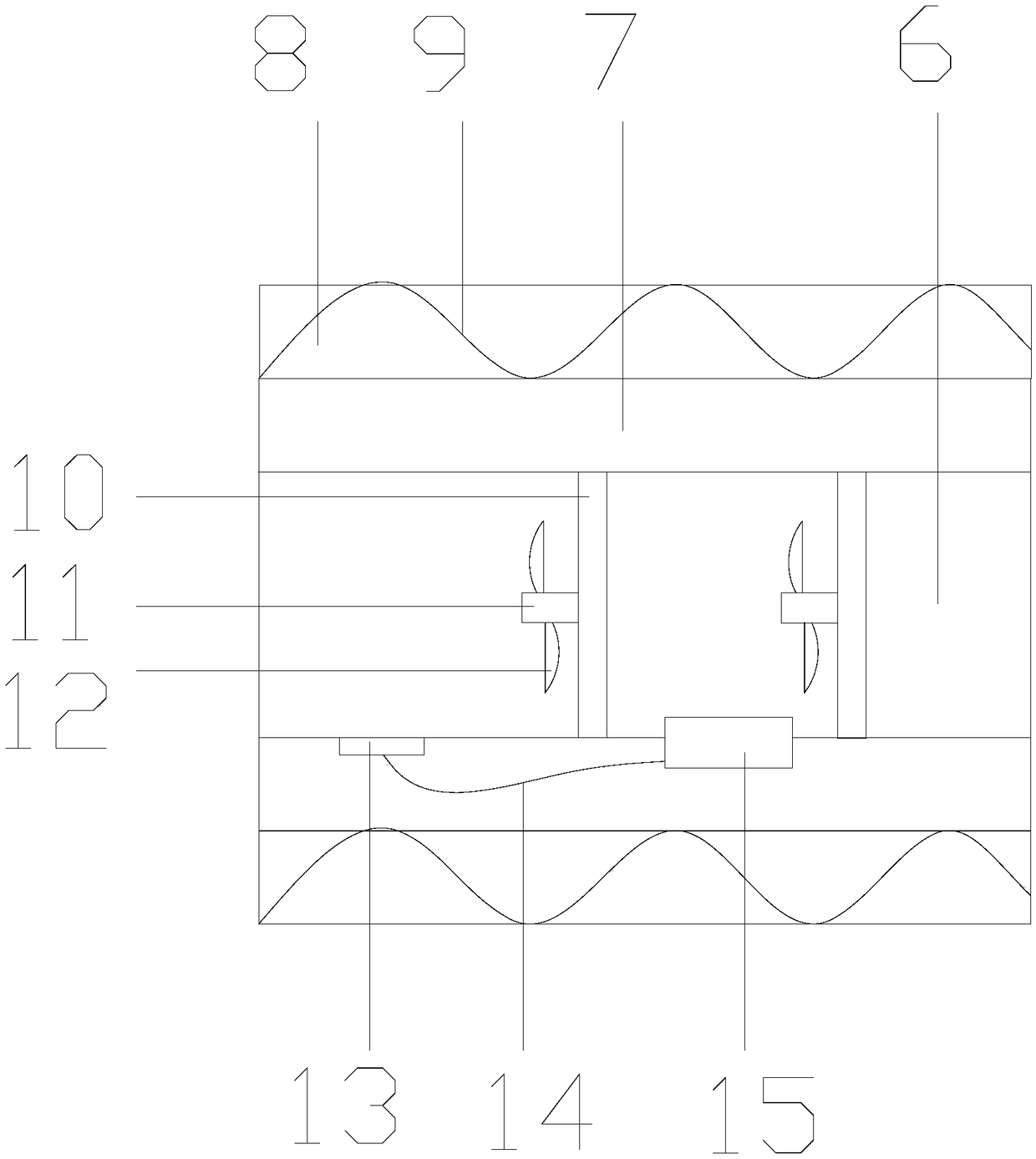

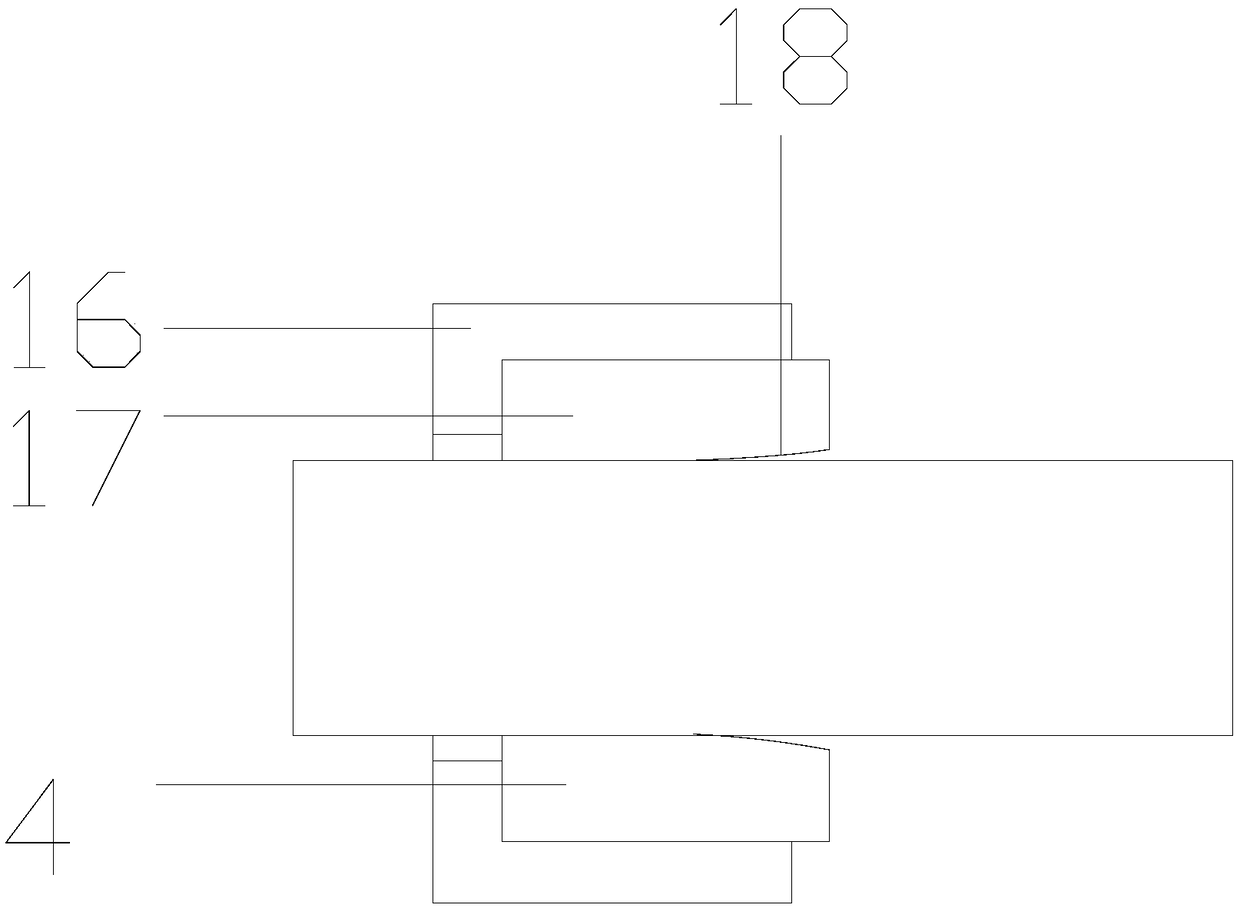

[0022] Such as Figure 1 to Figure 3 As shown, a pressure-resistant and explosion-proof delivery pipeline for oil treatment includes a pipeline body and an annular adapter 1 arranged at the bending part of the pipeline body; the pipeline body includes a first pipeline 2 and a second pipeline Two pipelines 3, the first pipeline 2 and the second pipeline 3 are straight pipelines, the annular adapter 1 is a circular pipeline connected end to end, the first pipeline 2 and the second The pipelines 3 are respectively connected to the sidewalls of the annular pipeline of the annular adapter 1, so that the oil flowing into the annular adapter 1 from the first pipeline 2 flows along both sides of the annular pipeline, and the second pipeline 3 and the annular adapter 1, which reduces the high-pressure strength of the transported liquid during the bending process of the pipeline, strengthens the protection performance of the oil pipeline, and avoids the burst damage of the bent part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com