Surface spray paint for metal frame and anchor for tundish cover and preparation method thereof

A metal frame and anchor technology, which is applied in the field of refractory materials, can solve the problems of human body hazards of asphalt paint, and achieve the effects of improving the utilization rate of raw materials, a good buffering effect, and improving the utilization rate of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A surface spray paint for a metal frame and an anchor for a tundish cover is prepared from the following raw materials in weight percentage:

[0036] High alumina refractory fiber 45%,

[0037] Silica powder with particle size ≤1.3μm 36%,

[0038] 10% of pure calcium aluminate cement with particle size ≤0.088mm,

[0039] α-alumina fine powder with particle size ≤0.088mm 4%,

[0040] Magnesia fine powder with particle size ≤0.088mm 5%,

[0041] Add allyl polyether 2020 accounting for 0.15% of the total weight of the above raw materials and water accounting for 33% of the total weight of the above raw materials.

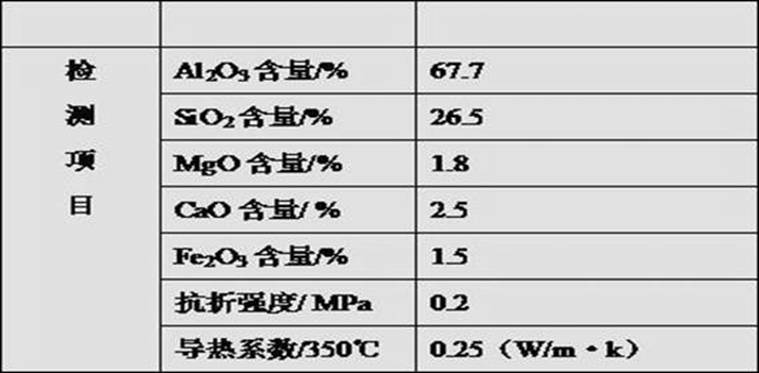

[0042] Wherein, the high-alumina refractory fiber is a by-product of fused mullite products; before the high-alumina refractory fiber is used as a raw material, the following treatment is first performed: the collected high-alumina refractory fiber is washed with clean water, and then Dry at 110±5°C for 1.8~2.5 hours to obtain high-alumina refractory fibers ...

Embodiment 2

[0049] A surface spray paint for a metal frame and an anchor for a tundish cover is prepared from the following raw materials in weight percentage:

[0050] High alumina refractory fiber 50%,

[0051] Silica powder with particle size ≤1.3μm 35%,

[0052] 7% of pure calcium aluminate cement with particle size ≤0.088mm,

[0053] α-alumina fine powder with particle size ≤0.088mm 3%,

[0054] Magnesia fine powder with particle size ≤0.088mm 5%,

[0055] Add allyl polyether 2020 accounting for 0.2% of the total mass of the above raw materials and water accounting for 35% of the total mass of the above raw materials.

[0056] Wherein, the high-alumina refractory fiber is a by-product of fused mullite products; before the high-alumina refractory fiber is used as a raw material, the following treatment is first performed: the collected high-alumina refractory fiber is washed with clean water, and then Dry at 110±5°C for 1.8~2.5 hours to obtain high-alumina refractory fibers with a...

Embodiment 3

[0063] A surface spray paint for a metal frame and an anchor for a tundish cover is prepared from the following raw materials in weight percentage:

[0064] High alumina refractory fiber 42%,

[0065] Silica powder with particle size ≤1.3μm 40%,

[0066] 10% pure calcium aluminate cement with particle size ≤0.088mm,

[0067] 4% of α-alumina fine powder with particle size ≤0.088mm,

[0068] Magnesium oxide fine powder with particle size ≤0.088mm 4%,

[0069] Add allyl polyether 2020 accounting for 0.15% of the total mass of the above raw materials and water accounting for 38% of the total mass of the above raw materials.

[0070] Wherein, the high-alumina refractory fiber is a by-product of fused mullite products; before the high-alumina refractory fiber is used as a raw material, the following treatment is first performed: the collected high-alumina refractory fiber is washed with clean water, and then Dry at 110±5°C for 1.8~2.5 hours to obtain high-alumina refractory fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com