Automatic constant-temperature heating system and control method thereof

A technology of constant temperature heating and control method, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of large volume, artificial irrigation, docking and sharing of purifying faucets, etc., to achieve a clean heating environment and reduce Bacteria growth and the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

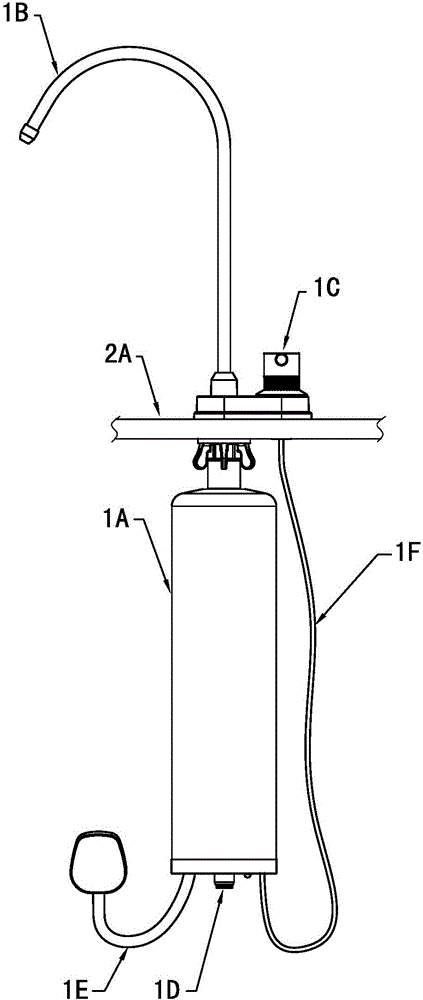

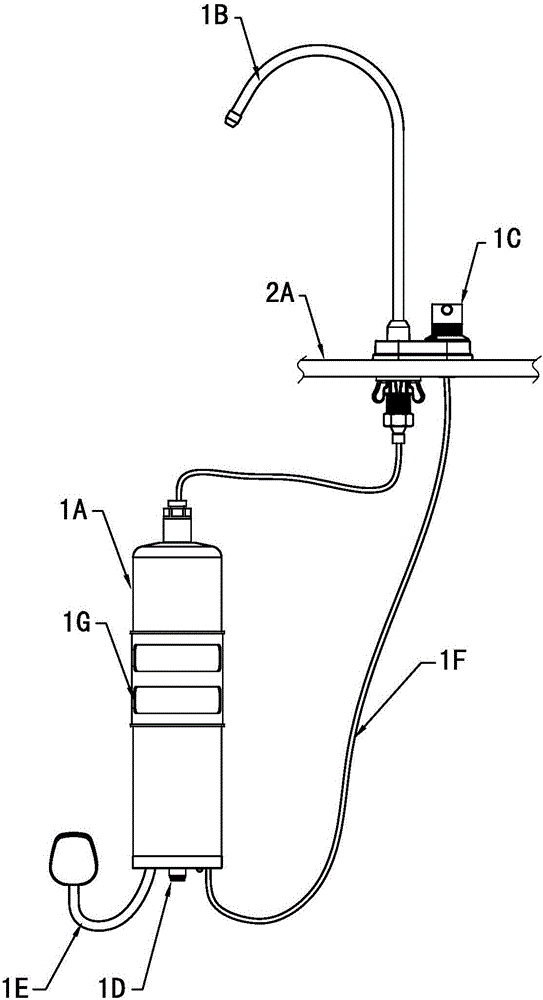

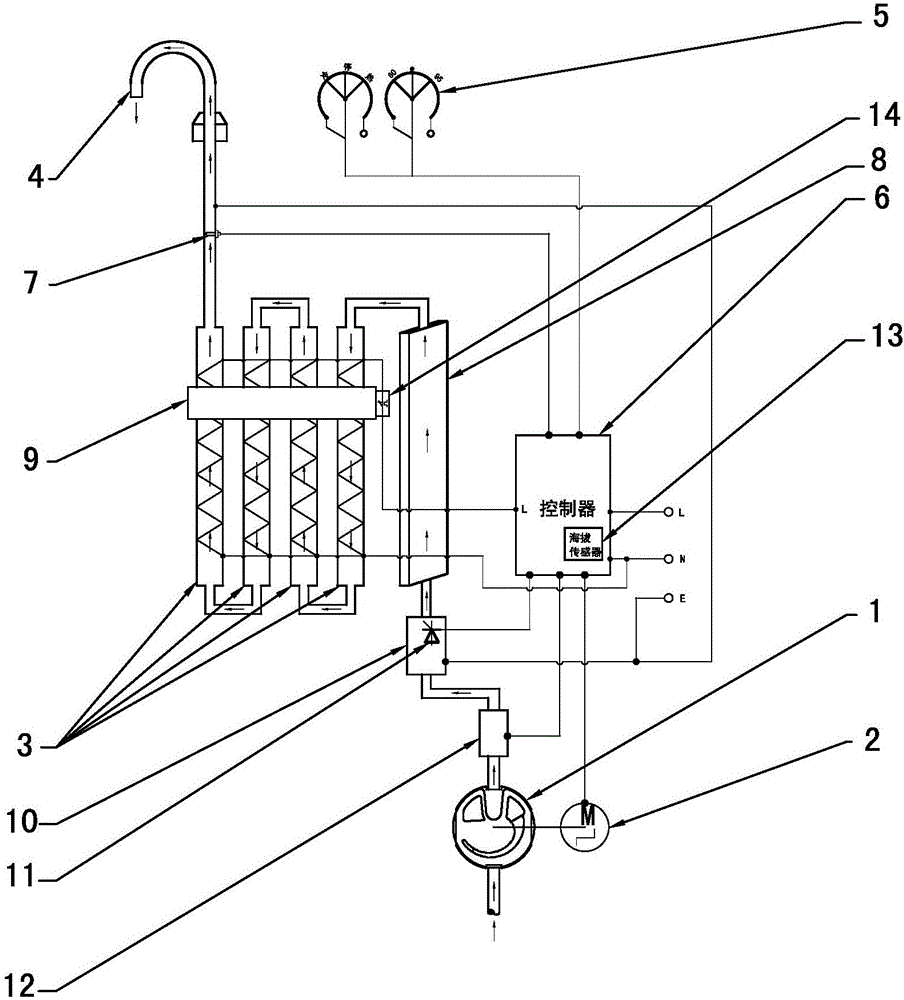

[0035] combine figure 1 and figure 2 As shown, an automatic constant temperature heating system includes a constant temperature heating unit 1A arranged under the table top 2A, an on-table control unit 1C and a water outlet unit 1B on the table top 2A, wherein the above-board control unit 1C is a knob switch 5, a water outlet The unit 1B is a faucet 4, and the rotary switch 5 is electrically connected to the constant temperature heating unit 1A through a signal line 1F. The water inlet 1D of the constant temperature heating unit 1A under the table is connected to pure water, and the constant temperature heating unit 1A is used for heating. The lower end of the constant temperature heating unit 1A is provided with a power cord 1E and a socket for connecting to a power supply. exist figure 1 Among them, the water inlet with external thread at the water outlet unit 1B on the stage is directly connected to the internal thread water outlet of the constant temperature heating uni...

Embodiment 2

[0061] According to the automatic constant temperature heating system proposed in the above embodiment, this embodiment proposes a control method for the automatic constant temperature heating system

[0062] Such as Figure 6 Shown, a kind of control method of automatic constant temperature heating system, comprises steps:

[0063] S1. When the user turns on the water flow through the knob switch 5 and sets the water temperature (that is, adjust the switch knob to the hot water level at this time, and adjust the temperature knob to the corresponding degree to set the corresponding water temperature), the knob switch 5. Transfer the water temperature setting value information to the controller 6;

[0064] S2. The controller 6 receives the water temperature setting value information, and obtains the outlet water temperature information sent by the temperature sensor 7, and the controller 6 judges the required water flow according to the water temperature setting value informat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com