Quasi-trapezoidal inclined baffle shell and tube heat exchanger

A shell-and-tube heat exchanger and baffle technology, which is applied to indirect heat exchangers, heat exchanger types, heat exchanger shells, etc., can solve the complex process and difficult production of continuous spiral baffle heat exchangers. and other problems, to achieve the effect of improving the heat transfer coefficient and comprehensive performance, reducing the pressure drop on the shell side, and improving the heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

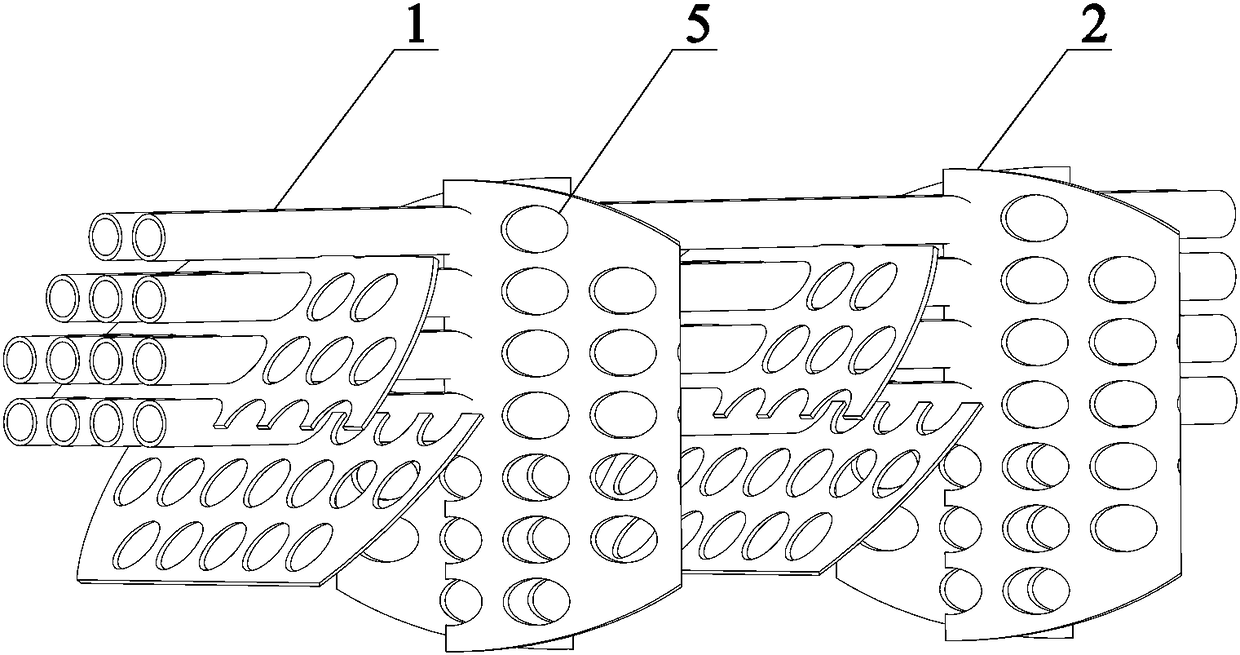

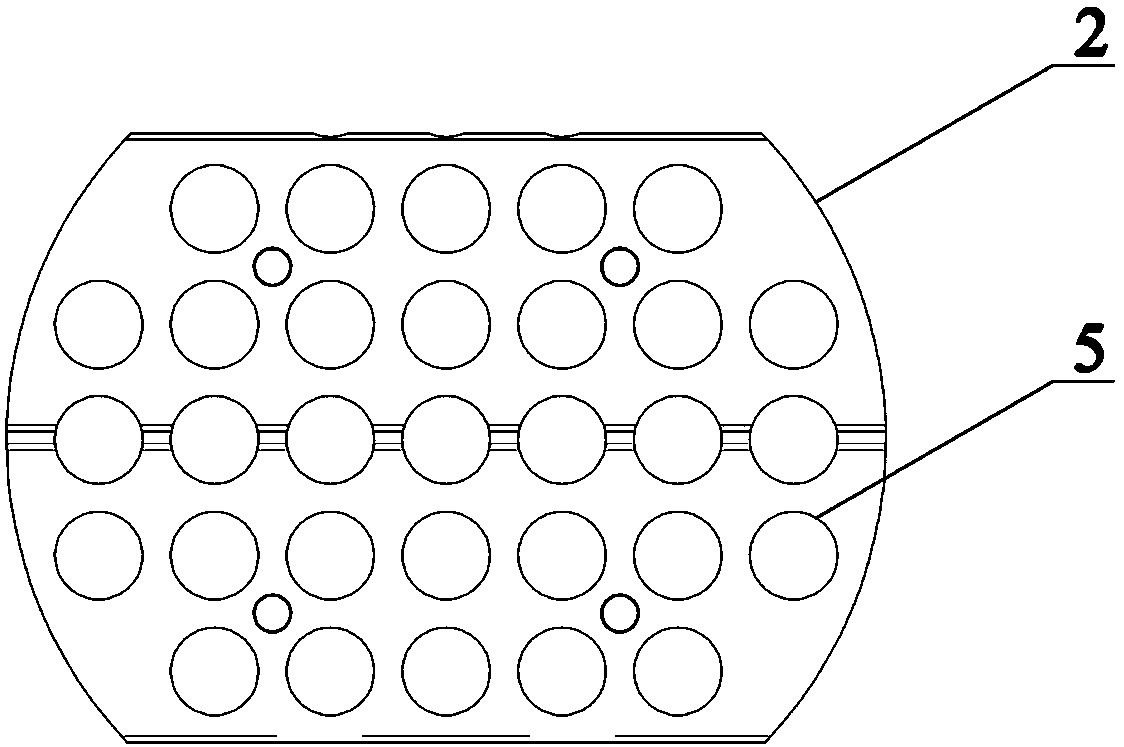

[0030] This embodiment provides a trapezoidal inclined baffle shell-and-tube heat exchanger, including a shell, a heat exchange tube 1, a tube sheet, tie rods and a trapezoidal baffle 2, such as Figure 1~5 As shown, two adjacent sets of trapezoidal baffles 2 are arranged orthogonally, and two sets of trapezoidal baffles 2 are arranged in parallel, each group includes two parallel trapezoidal baffles 2, and the trapezoidal baffles The flow plate 2 corresponds to the heat exchange tube 1 with several holes 5 evenly distributed, the heat exchange tube 1 is arranged through the hole 5, the trapezoidal baffle 2 is arranged obliquely, and the trapezoidal baffle 2 and The heat exchange tube 1 includes an angle α=45°, and the flow state schematic diagram when the shell-side fluid flows through a set of trapezoidal baffles 2, as shown in Figure 9 As shown, after the shell-side fluid flows in one direction in one set of trapezoidal baffles 2, it flows in another direction after flowin...

Embodiment 2

[0034] Such as Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that two sets of alternate trapezoidal baffles 2 are arranged symmetrically;

Embodiment 3

[0036] Such as Figure 8 As shown, the difference between this embodiment and the above-mentioned embodiment is that each group includes three trapezoidal baffles 2, and the distance between the trapezoidal baffles 2 in each group is The quasi-trapezoidal baffles 2 in the middle of each group are cut from the two ends of the major axis by the elliptical plate, and the height is The bow-shaped plate is made; the trapezoidal baffles 2 at both ends of each group are cut from the two ends of the long axis of the elliptical plate with a height of He Gaowei made of a segmented plate, where R is the radius of the shell and the major axis of the ellipse is The minor axis is 2R.

[0037] In other embodiments, the difference from the above embodiments is that: the angle α between the trapezoidal baffle plate 2 and the heat exchange tube 1 can be set according to requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com