Spiral bevel gear tooth root bending stress testing method in consideration with dynamic load based on similarity theory

A technology of spiral bevel gear and bending stress, which is applied in the field of life design and prediction analysis of spiral bevel gear transmission system, and can solve problems such as difficult verification work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0132] Step (1): Selection of the main parameters in the dynamic load similarity model of the spiral bevel gear;

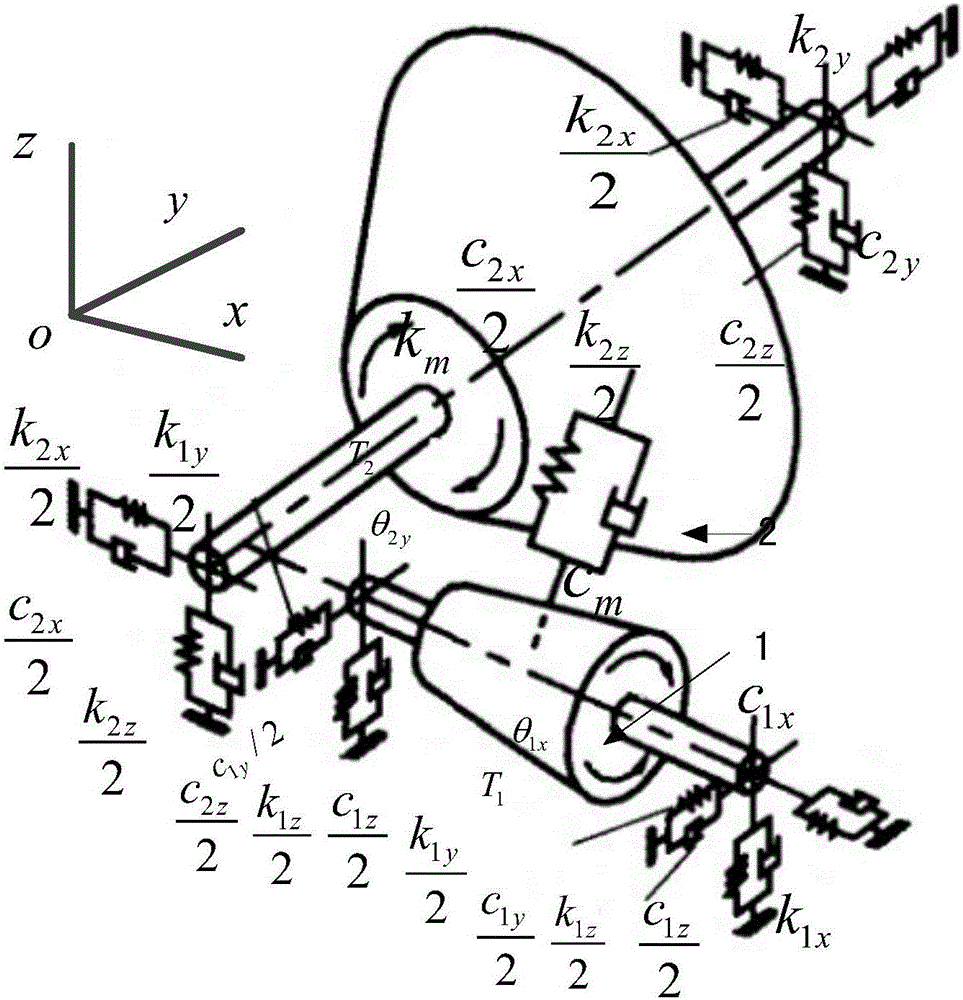

[0133] The relative displacement along the normal direction of the meshing point between the meshing points of two bevel gear tooth surfaces due to vibration and error is:

[0134] lambda n =(x 1 -x 2 )a 1 -(y 1 -y 2 )a 2 -[(z 1 + r 1 θ 1y )-(z 2 + r 2 θ 1x )]a 3 -e n (t).

[0135] Where: x i 、y i 、y i (i=1,2) are the vibration displacements of the driving wheel 1 and the driven wheel 2 along the x-axis, y-axis and z-axis respectively, where i=1 represents the driving wheel 1, i=2 represents the driven wheel 2; θ 1x , θ 2y are the torsional vibration displacements of the driving wheel 1 around its own axis x-axis and the driven wheel 2 around its own axis y-axis, where the driving wheel 1 is smaller than the driven wheel 2, a 1 =cosδ 1 sinα n , a 2 =cosδ 1 cosα n sinβ 1 , a 3 =cosα n cosβ 1 , e n (t) is the normal transmission static ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com