An in-situ test device for seepage in fractured rock mass that can be assembled and disassembled

A cracked rock mass, in-situ test technology, applied in the field of rock mass seepage characteristics research, can solve the problems of lack of natural stress state, poor effectiveness, heavy workload, etc., to overcome the limitation of sample size, easy assembly and disassembly, Guaranteed Effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

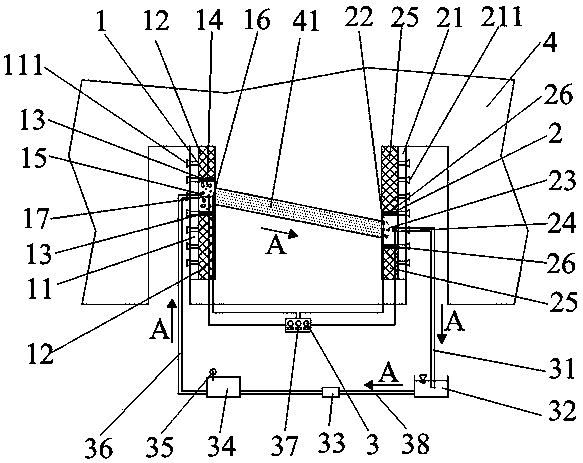

[0016] see figure 1 As shown, the present invention is made up of the first fixed closing device 1, the second fixed closing device 2 and the control system 3, the first fixed closing device 1 and the second fixed closing device 2 are respectively fixedly arranged in the rock mass 4, and the control system 3 respectively connected with the first fixed closing device 1 and the second fixed closing device 2, and the first fixed closing device 1 and the second fixed closing device 2 communicate with the crack 41 respectively;

[0017] The first fixed sealing device 1 comprises a first organic glass 11, a first pressure sensor 16 and a temperature sensor 17, the first organic glass 11 is fixedly arranged in the rock mass 4, and there are several first water inlets on the first organic glass 11 111, there are two sets of first sealing capsules 12 and first water-proof layers 13 between the first plexiglass 11 and the rock mass 4, and the two groups of first sealing capsules 12 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com