Underground direct measuring integral device for coal seam methane content

A coal seam gas and measurement device technology, which is applied in the direction of measurement devices, fuel oil testing, instruments, etc., can solve the problems of small maintenance, long measurement period, large engineering quantity, etc. continuous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

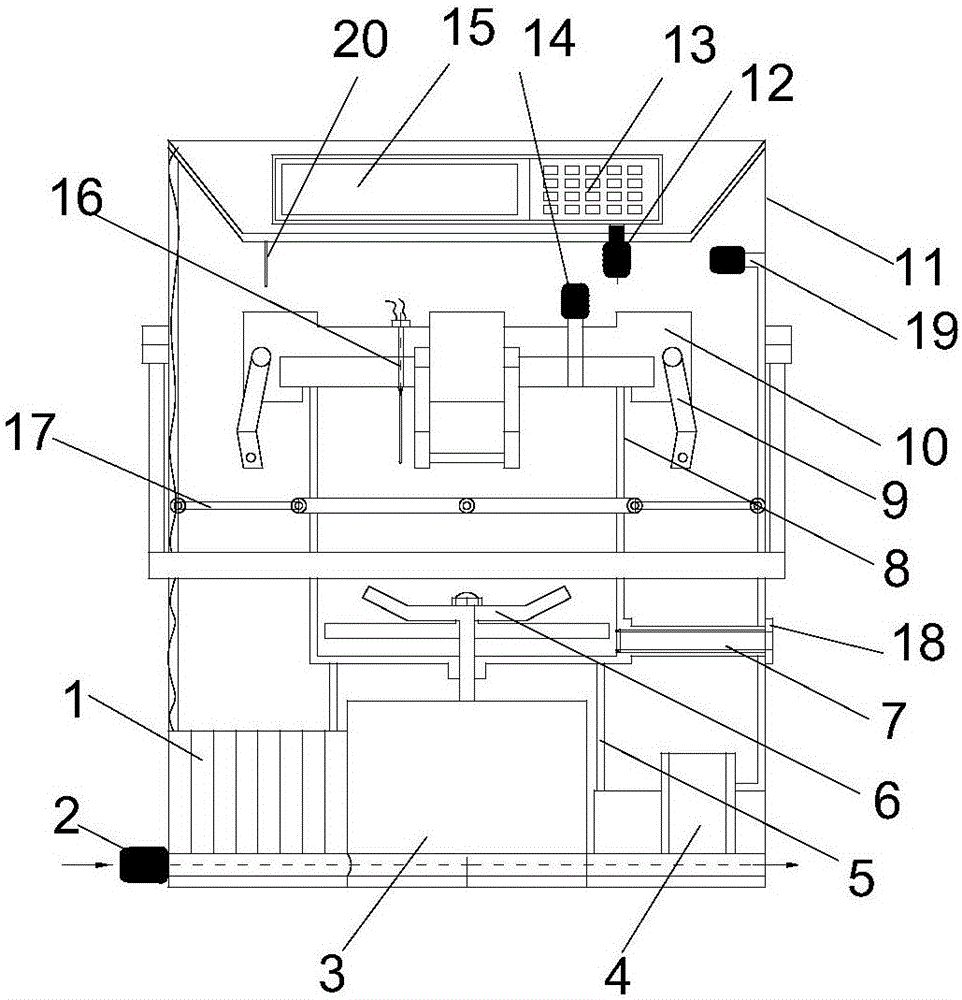

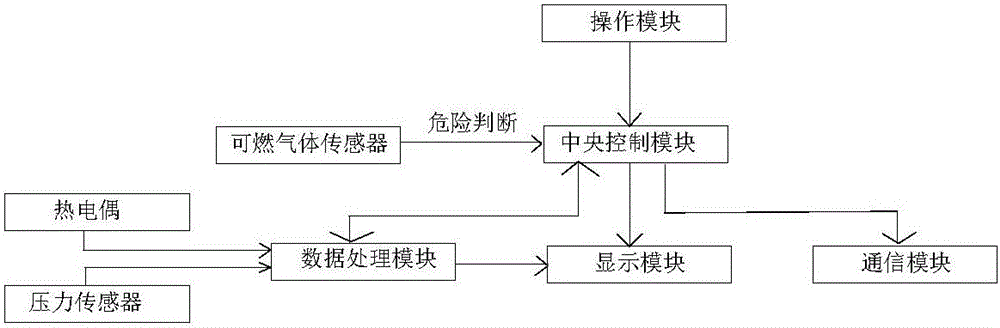

[0022] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a functional block diagram of the processing unit of the present invention, as shown in the figure: the coal seam gas content underground direct measurement integrated device of the present invention includes a casing 11, a sealed crushing desorption tank 8 and a processing unit;

[0023] The sealed pulverizing desorption tank 8 is arranged in the shell 11, and the sealed pulverizing desorption tank 8 is positioned by the fixture 17 and the support rod 5; the sealed pulverizing desorption tank is provided with a pressure measuring device and a pressure measurement device for measuring its internal pressure. A temperature measuring device for measuring its internal temperature, the output ends of the pressure measuring device and the temperature measuring device are connected to the processing unit;

[0024] The shell is the carrier of the whole device and each device in the device; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com