Direct rapid measuring method capable of desorbing mash gas content with coal seam

A gas content, rapid determination technology, applied in the preparation of test samples, special data processing applications, instruments, etc., can solve the problems of high measurement cost, production impact, abnormal gas emission, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

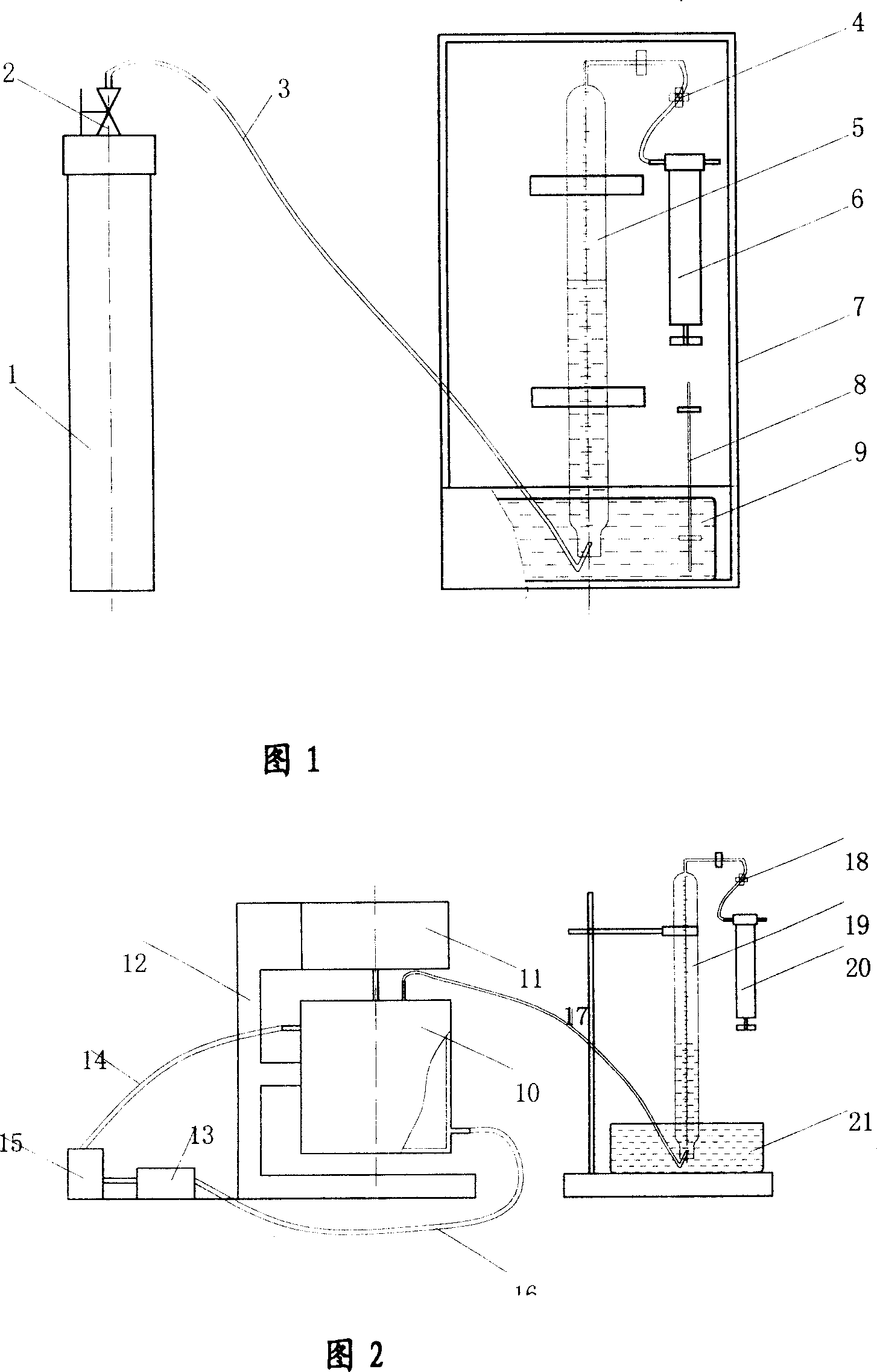

Method used

Image

Examples

Embodiment 1

[0083] Embodiment 1: Now take a certain mine of Huainan Mining (Group) Co., Ltd. as an example to illustrate the measurement process. The steps are as follows:

[0084] (1) Underground coal core sampling

[0085] Drilling layout: drilling through layers in a floor lane of the mine;

[0086] Drilling construction: Drilling is carried out vertically to the coal seam, the inclination angle is 66°, the hole diameter is φ75mm, and the drilling is stopped after seeing the coal seam floor at 55m, and the drill pipe is withdrawn.

[0087] Coal core taking: send the φ73mm single-layer core pipe to the bottom of the coal seam under the state of pressurized air, and start drilling. The time to start drilling is recorded as 18:06 on the 24th of a certain month in a certain year. Drill until the coal sample is filled with coal. Up to the sample cylinder, the end time is 18:18 on the same day, and the drilling time is t 1 After 12 minutes, exit the core tube, put the coal core into the co...

Embodiment 2

[0111] Embodiment two: now take Huainan Mining (Group) Co., Ltd. ××× mine as an example to illustrate the measurement process, and its steps are as follows:

[0112] (1) Underground coal core sampling

[0113] Drilling layout: construction of layer-by-layer drilling at the driving face of Huainan ××× mine coal roadway;

[0114] Drilling construction: Drilling is carried out along the direction of the coal seam, with an inclination of +2°, a hole diameter of φ108mm, and a drilling depth of 23m. Entering the original gas pressure zone, stop drilling, withdraw the drill pipe, and start drilling at 9:05 on the 5th of a certain year. ;

[0115] Coal core taking: Send the φ90mm double-layer core pipe to the bottom of the coal seam under the state of pressurized air, and start drilling. The time to start drilling is recorded as 9:46 on the 5th of a certain month in a certain year. Drill until the coal sample is filled with coal. Up to the sample cylinder, the end time is 10:00 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com