Measuring system and method for hydrogen sulfide gas content in coal seam

A technology of gas content and measurement system, which is applied in the field of coal seam operations, can solve the problems of lack of instruments and technologies, and achieve the effects of short measurement period, small measurement engineering quantity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

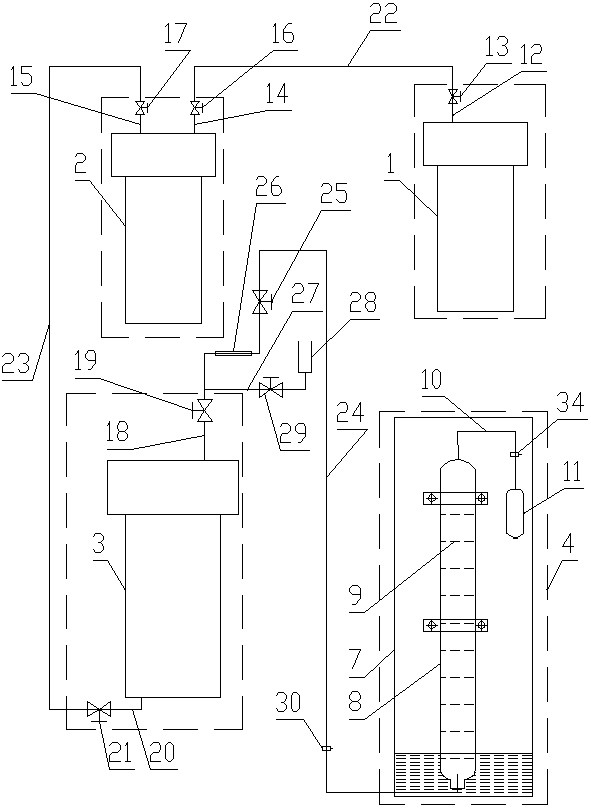

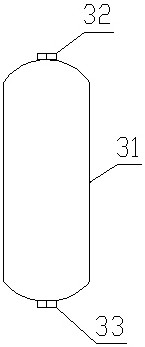

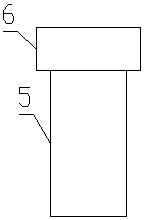

[0056] Such as Figure 1 to Figure 3 As shown, the coal seam hydrogen sulfide gas content measuring system of the present invention comprises coal sample tank 1, gas sample tank 2, reaction tank 3 and desorption instrument 4, and coal sample tank 1, gas sample tank 2 and reaction tank 3 are identical in structure, all comprise A tank body 5 and a tank cover 6 detachably connected to the top of the tank body 5;

[0057] Desorption instrument 4 comprises the box body 7 of open top, and the bottom of box body 7 is filled with water, is provided with measuring tube 8 in the box body 7, is provided with scale mark 9 on measuring tube 8, and the bottom end of measuring tube 8 is provided with opening, The bottom opening of the measuring tube 8 is located below the water surface in the casing 7, the top of the measuring tube 8 is higher than the water surface in the casing 7 and is positioned at the top of the casing 7, the top of the measuring tube 8 is connected with a suction hose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com