Method for measuring static state weight difference in two sides of elvator balancing coefficient

A technology of balance coefficient and measurement method, applied in static/dynamic balance test, measurement device, machine/structural component test, etc., can solve problems such as difficulty in obtaining elevator balance coefficient, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

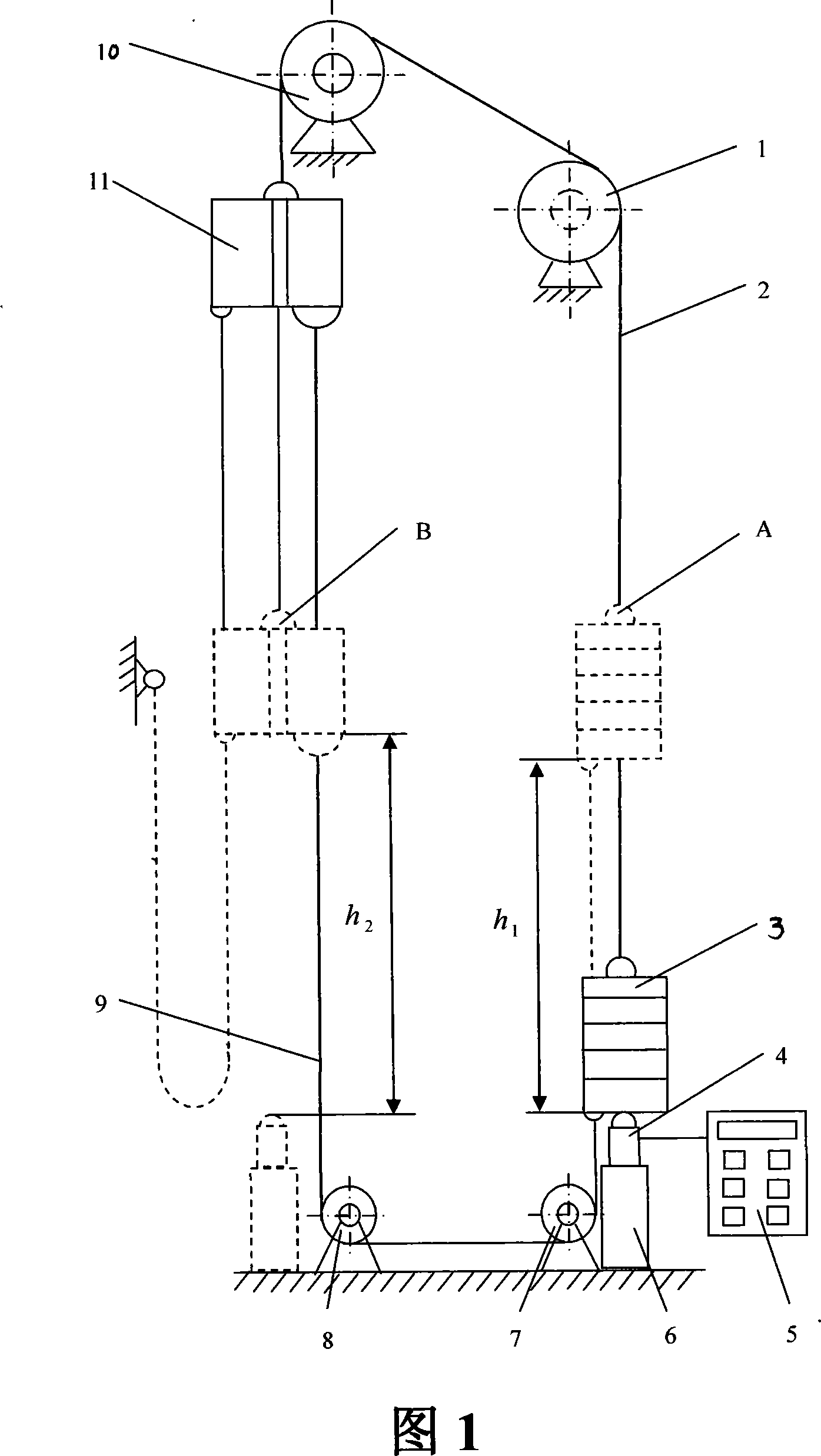

[0027] As shown in Figure 1, the elevator traction wire rope 2 is connected to the car 11 and the counterweight 3 through the traction sheave 10 and the driven wheel 1, and the compensation chain 9 under the car 11 is connected to the bottom of the counterweight 3 through the pulleys 7, 8 to transmit force. The device 4 is installed on the buffer or bracket 6, and the output of the force transmitter 4 is connected to the test instrument 5.

[0028] When measuring, first adjust the car 11 and the counterweight 3 to an appropriate position, so that the connecting points A and B of the traction rope 2 with the car 11 and the counterweight 3 are in the same horizontal position (the position shown by the dotted line in the figure) ) To record the location. At the same time to obtain μ, N, ρ 1 , Ρ 2 value.

[0029] When the elevator is empty, run the elevator car 11 to the top of the elevator hoistway, make the counterweight 3 descend to the bottom of the hoistway, and keep the distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com