Lamp bar fixed structure, backlight module and displayer

A technology for fixing structures and light strips, which is applied in the directions of instruments, optics, nonlinear optics, etc., can solve the problems of increased cost and cumbersome assembly, and achieve the effects of easy disassembly, simplified assembly process, and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

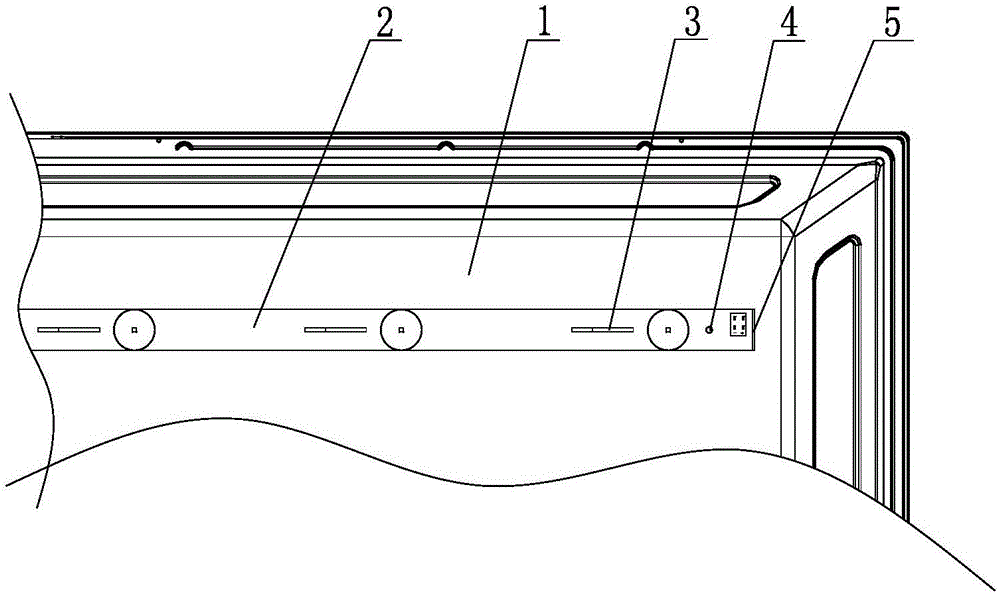

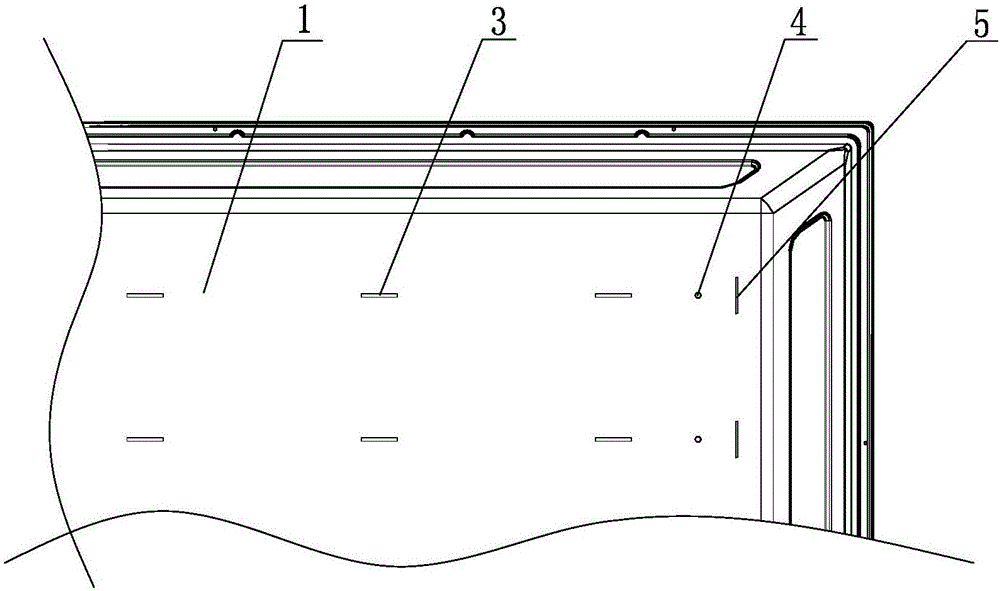

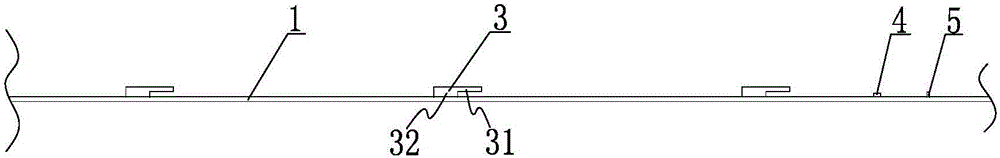

[0033] Please refer to the attached figure 1 to attach Figure 4 , a light bar fixing structure, used for positioning and fixing the light bar 2 and the back plate 1, including the light bar 2 and the back plate 1, wherein:

[0034] Several pre-positioning holes 21 and at least one position-limiting positioning hole 22 are provided on the light bar. In this embodiment, the pre-positioning holes are horizontally arranged on the light bar, and two limit positioning holes are provided, which are respectively symmetrically distributed on the side near the end of the light bar at both ends.

[0035] The back plate can be made of metal, and there are several hanging lugs 3 corresponding to the pre-positioning holes one by one and at least one positioning post 4 cooperating and fixedly connecting with the limiting positioning holes 22 protruding from the back plate. In this embodiment, the hanging ear 3 includes a connecting part 32 and a pressing part 31, the connecting part 32 pr...

Embodiment 2

[0044] The only difference between this implementation and Embodiment 1 is the structure of the limit stopper. The limit stopper in this embodiment is replaced by a blocking strip longitudinally arranged on the back plate, which is used to limit the end of the light bar. The bottom can also prevent the light bar from slipping out, and the structure is simple. The features of other components of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com