DCS control method for acid production process in hydrogen chloride production

A control method, hydrogen chloride technology, applied in the direction of program control, electrical program control, comprehensive factory control, etc., can solve problems such as high labor intensity, affecting equipment safety, chlorine gas ratio imbalance, etc., achieve high degree of automation, reduce production costs, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

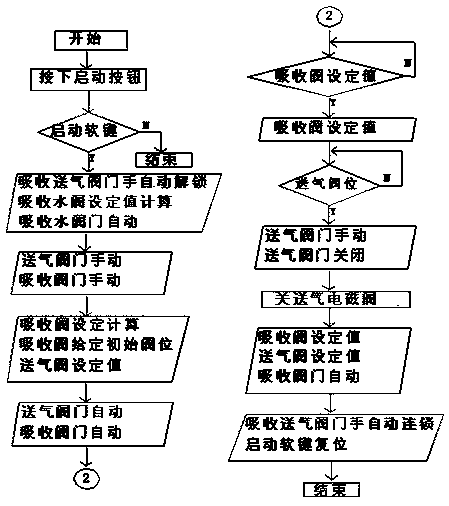

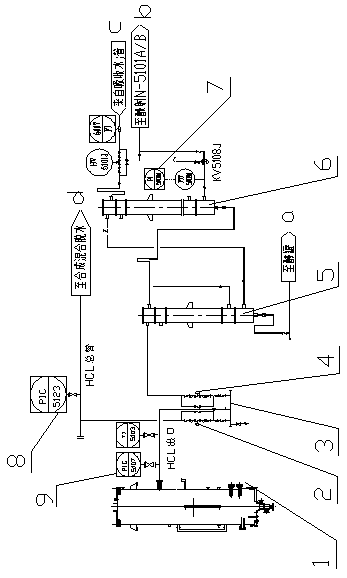

[0033] Refer to attached figure 1 , the specific embodiment of the present invention is as follows:

[0034] A DCS control method for the acid production process in the production of hydrogen chloride: in the production of hydrogen chloride, the hydrogen chloride gas produced by the synthesis furnace (1) is exported from the bottom of the cooler of the synthesis furnace through the hydrogen chloride outlet pipe, and enters the hydrogen chloride distribution table (3), where the hydrogen chloride The outlet pipe is equipped with a hydrogen chloride outlet pressure gauge PIC5107 (9); the hydrogen chloride distribution table is equipped with an absorption regulating valve PV5123A (4) and an air supply regulating valve PV5123B (2); the hydrogen chloride main pipe is equipped with a hydrogen chloride main pipe pressure gauge PIC5123 (8) The hydrogen chloride gas is sent to the falling film absorber to absorb hydrochloric acid under the control of the absorption regulating valve PV5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com