Capacitive force sensing touch panel

A touch panel, capacitive technology, applied in the direction of electrical digital data processing, instrumentation, data processing input/output process, etc., can solve the problem that capacitive touch panels are difficult to obtain pressure sensing results, pressure sensing distortion, capacitance Sensing volume changes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

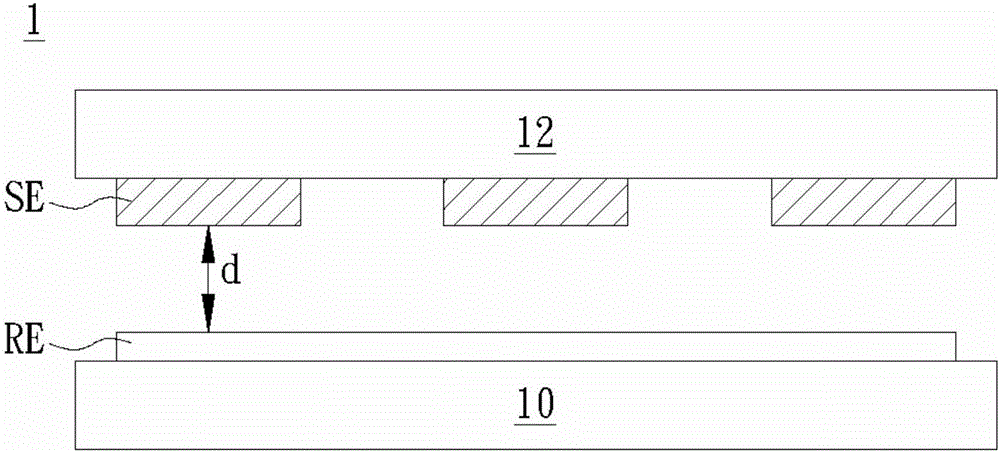

[0104] A specific embodiment according to the present invention is a capacitive pressure sensing touch panel. In this embodiment, the capacitive pressure sensing touch panel of the present invention can have different touch panel structures such as in-cell, on-cell or out-cell, and can be shielded by arranging opposite upper electrodes or Dividing the electrodes into touch-sensing electrodes and pressure-sensing electrodes according to their functions effectively prevents the capacitive sensing value from being distorted by the change of finger pressing area during pressure sensing, thereby improving the deficiencies of the prior art.

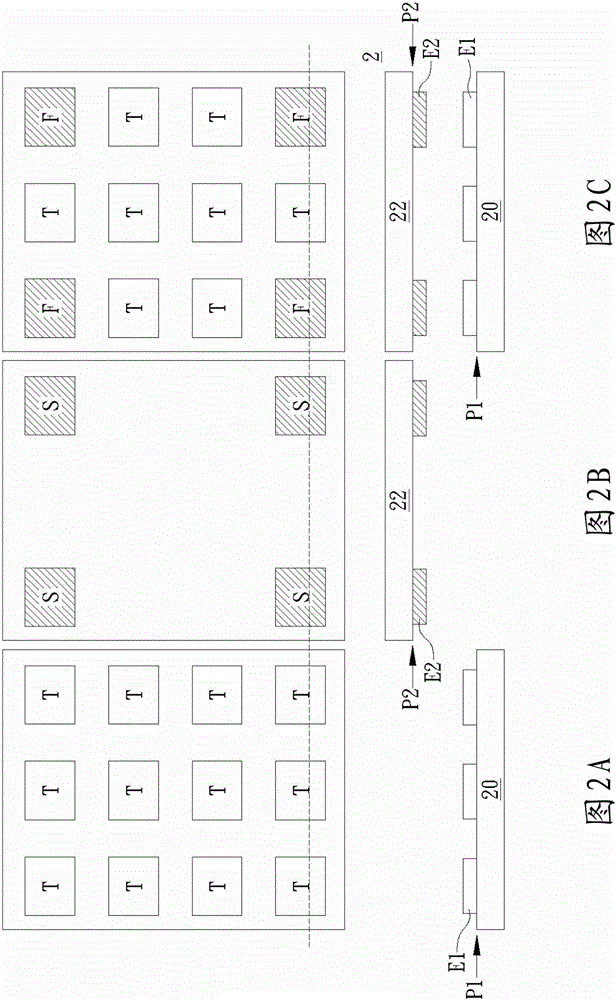

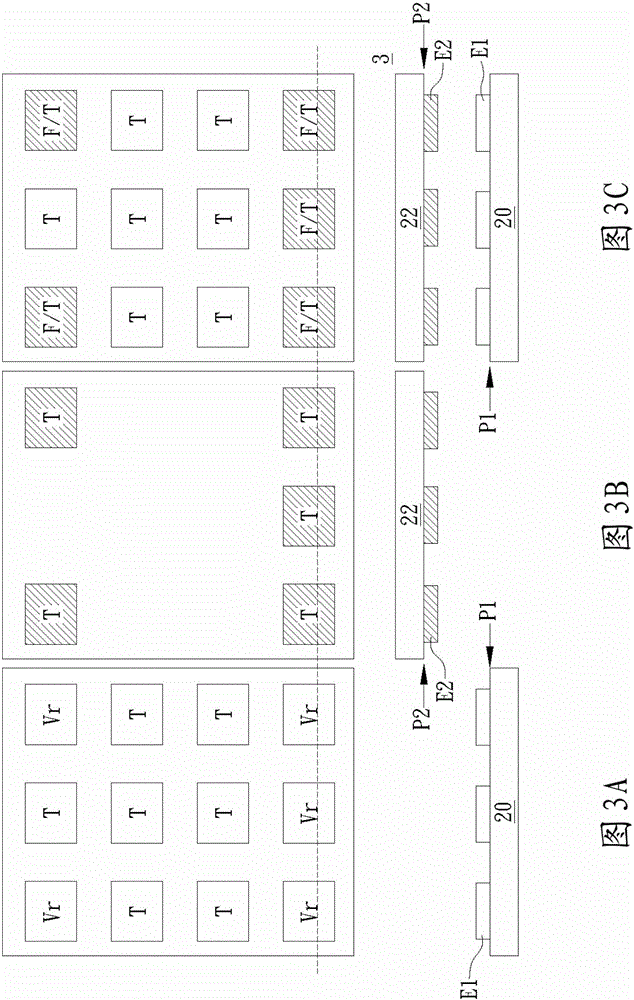

[0105] First, please refer to FIG. 2A to FIG. 2C , in this embodiment, the capacitive pressure sensing touch panel includes a plurality of pixels. The stacked structure 2 of each pixel includes a first substrate 20 , a second substrate 22 , a plurality of first electrodes E1 and a plurality of second electrodes E2 . Wherein, the plurality of f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com