A pole piece processing technology

A processing technology and pole piece technology, applied in the field of pole piece processing technology, can solve the problems of pole piece burrs, different pole piece elongation, pole piece serpentine bending, etc., so as to improve the yield, avoid wrinkling problems, and improve production The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

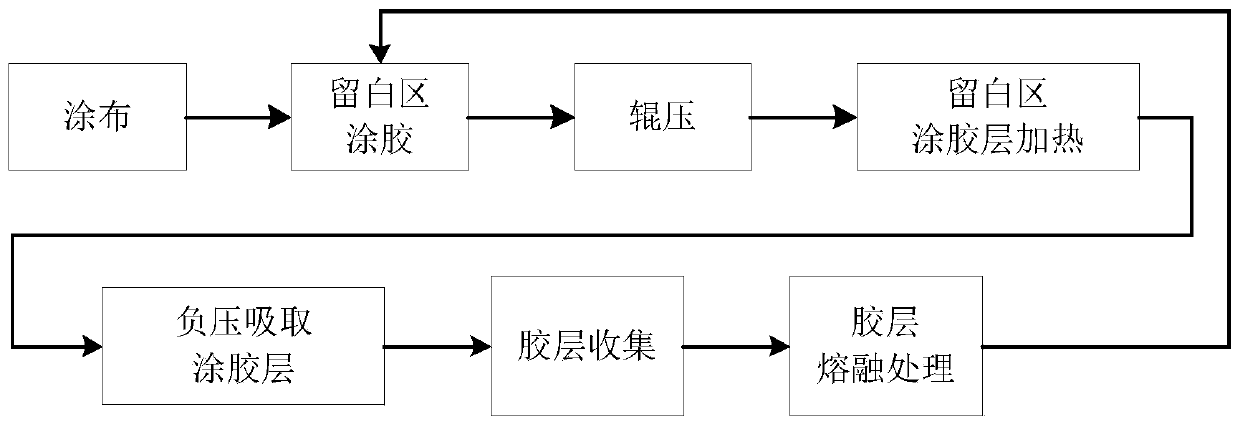

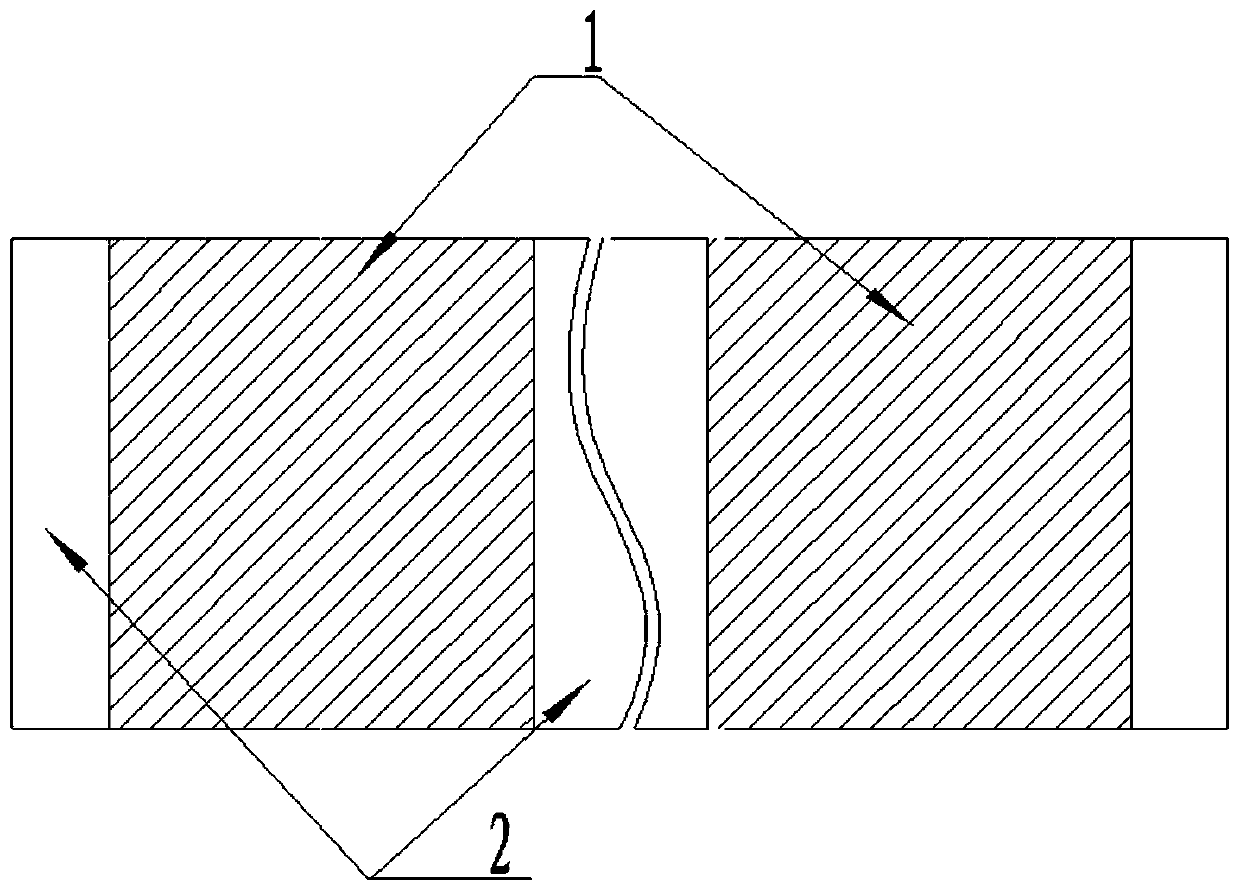

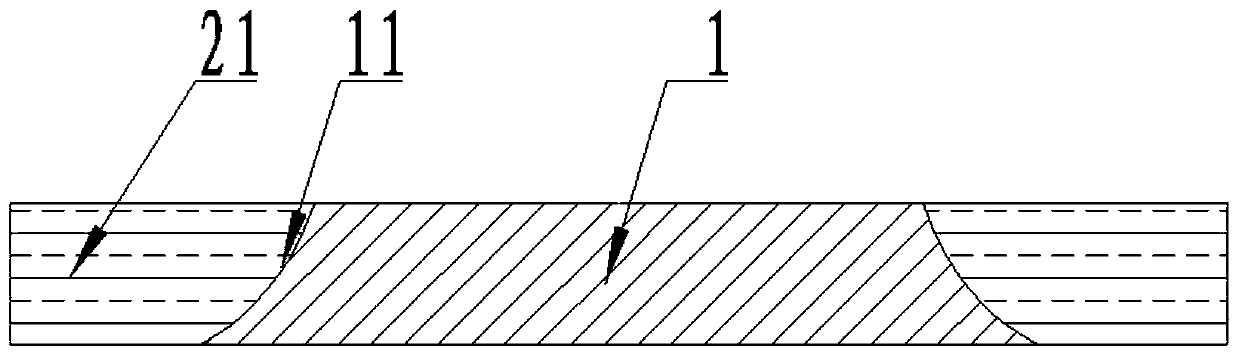

[0019] Such as figure 1 , figure 2 As shown, continuous coating is carried out on the front and back sides of the current collector of the pole piece. There are multiple coating areas 1 evenly distributed in the width direction of the pole piece, and vertical blank areas 2 are distributed between the coating areas 1 . The edge 11 on both sides of the coating area 1 is thinned, and the coating thickness of the edge 11 of the coating area is less than the thickness of other parts of the coating area 1, such as image 3 shown. The front and back coating areas of the pole piece are symmetrical. Melt the heat-sensitive adhesive and apply it to the blank area 2 of the pole piece by extrusion coating to form an adhesive layer 21. The thickness of the adhesive layer 21 is the same as that of the coating area 1. At the same time, the adhes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com